Method for changing A356 alloy primary aluminum liquid using cerium-enriched mixing rare earth

A cerium-rich mixed rare earth and mixed rare earth technology, which is applied in the field of cerium-rich mixed rare earth metamorphic A356 alloy primary aluminum liquid, to achieve the effects of good heredity, good metamorphic effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

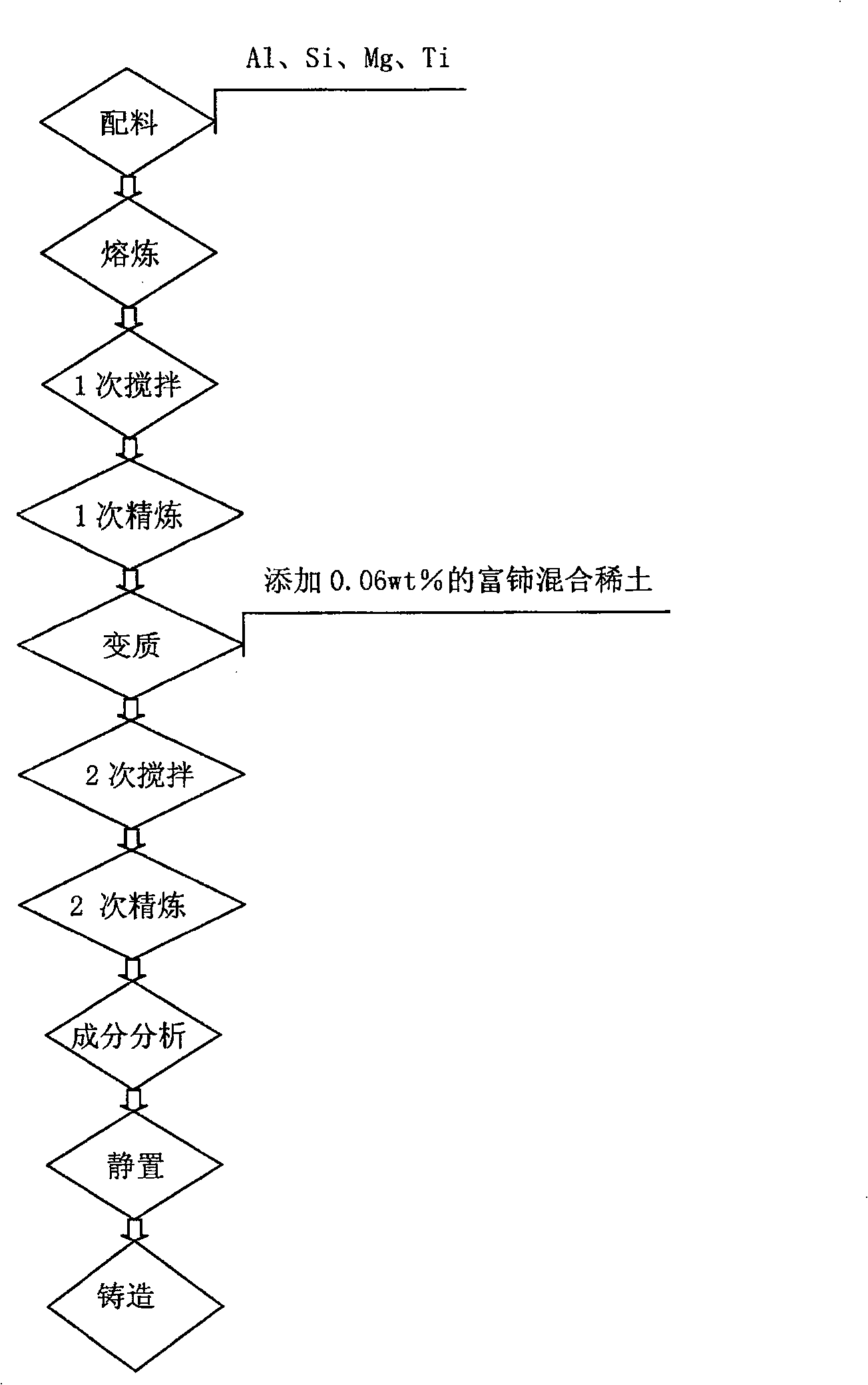

[0015] In the industrial mixing furnace (16t) of the aluminum alloy foundry, first add 0.8t of solid metal silicon particles; then add 10t of aluminum melt and 1.75t of titanium-containing primary aluminum liquid; then add 44kg of pure metal magnesium; smelting and refining after batching ; After refining and removing slag, add 61kg of cerium-rich mixed rare earth master alloy (Al-6.78%wtRE).

[0016] The specific process parameters are as follows:

[0017] Melting temperature: 736°C

[0018] Melting time: 120min

[0019] Stirring time for the first time: 30min

[0020] The first refining temperature: 689°C

[0021] The first refining time: 40min

[0022] Refining agent dosage: 72kg

[0023] Metamorphic temperature: 736°C

[0024] Metamorphic time: 10min

[0025] The second stirring time: 10min

[0026] Second refining temperature: 689°C

[0027] Second refining time: 40min

[0028] Standing time: 40min

[0029] Casting temperature: 677°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com