Manganese deoxidier and its preparation method and application

A deoxidizer and manganese-based technology, applied in the direction of chemical change purification/separation, etc., can solve the problems of low deoxidation capacity and high regeneration temperature, achieve large deoxidation capacity, improve mechanical strength, and prolong the effect of regeneration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

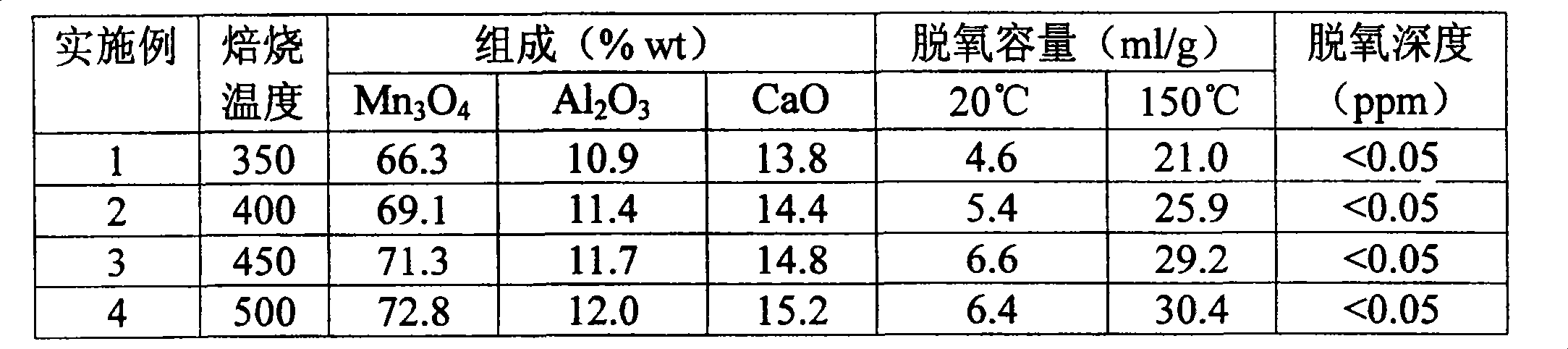

Embodiment 1~4

[0046] Weigh 420g triangular rhomboid MnCO 3 Fine powder, 60g pseudo-boehmite powder (bulk density 0.28g / ml, specific surface area 280m2 after roasting at 450°C 2 / g, weight loss 25%), 60g CaO fine powder, the three are fully mixed. Add an appropriate amount of distilled water and knead well. Then use extruder to prepare strips of Φ5; place overnight and dry in the air; dry at 120°C for 3 hours; cut into small sections with a length of 3 to 5 mm after cooling. The sample was evenly divided into 4 parts, which were respectively fired at 350, 400, 450, and 500° C. under an air atmosphere for 4 hours (Examples 1-4). Take a small amount of samples and use X-ray energy spectrometer to analyze the Mn of four deoxidizers 3 o 4 、Al 2 o 3 , CaO content. Take 50ml of deoxidizer respectively and put them into a Φ25 stainless steel reactor, and pass H at 280°C 2 Reduction 12h, H 2 Airspeed is 10h -1 . After cooling down, under the pressure of 0.4Mpa, respectively at the tempera...

Embodiment 5~8

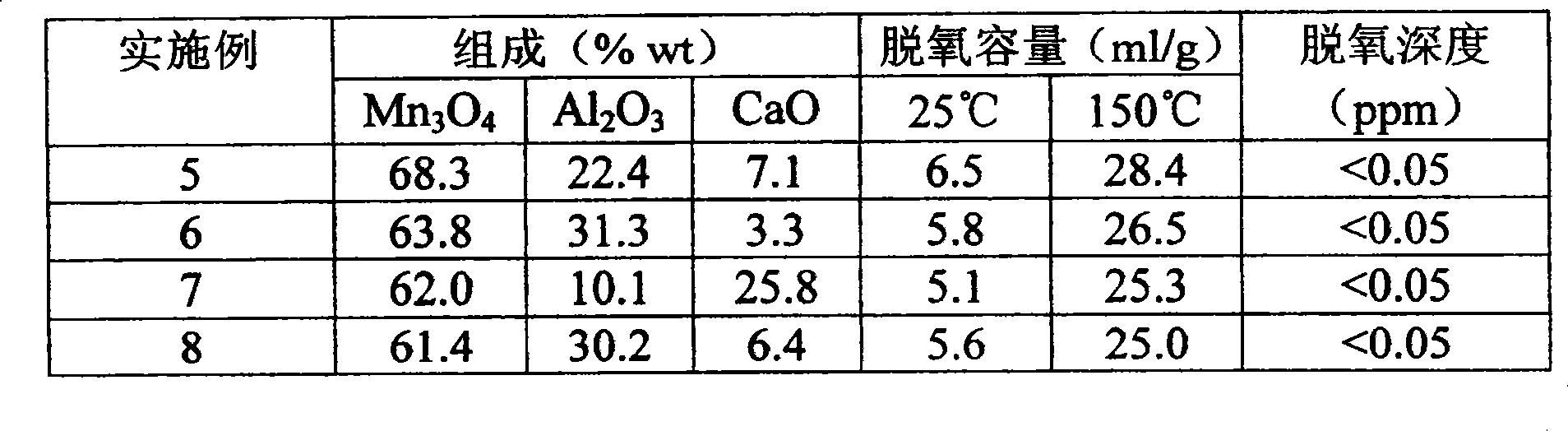

[0050] According to the trigonometric rhombohedral MnCO 3 : Pseudoboehmite (bulk density 0.28g / ml, specific surface area 260m2 after calcination at 450°C 2 / g, weight loss 24%): CaO is respectively in weight ratio 7:2:0.5 (embodiment 5), 7:3:0.25 (embodiment 6), 7:1:2 (embodiment 7), 7:3 : 0.5 (embodiment 8) prepares four parts of samples, fully mixes, each adds appropriate amount of 1.0% dilute nitric acid and kneads, then prepares the strip shape of Φ5 with extruder; Place overnight, dry in the air; 120 ℃ of oven dry 3 hours ; After cooling, cut into small sections with a length of 3 to 5 mm. It was then fired at 450°C for 4 hours in an air atmosphere. The prepared deoxidizer was activated and evaluated under the same operating conditions as in Example 1, and the evaluation results are shown in Table 2.

[0051] Table 2 Chemical composition and deoxidizer performance of Examples 5-8

[0052]

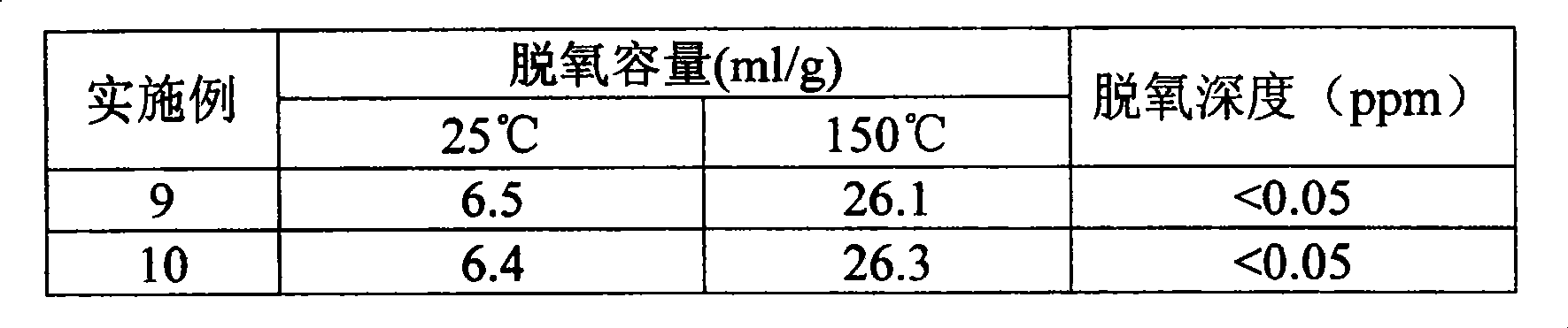

Embodiment 9

[0054] 10 grams of MgO was used to replace 10 grams of CaO powder in Example 3, and the deoxidizer was prepared, activated and evaluated under the same conditions as in Example 3. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com