Vulcanization mechanical electrical heating device

An electric heating device and technology for heating devices, which are applied to tires, other household appliances, household appliances, etc., can solve the problems of difficult close contact of electric heating pipes, complicated processing of steam hot plates, inconvenient equipment maintenance, etc., and achieve small surface temperature difference, Simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

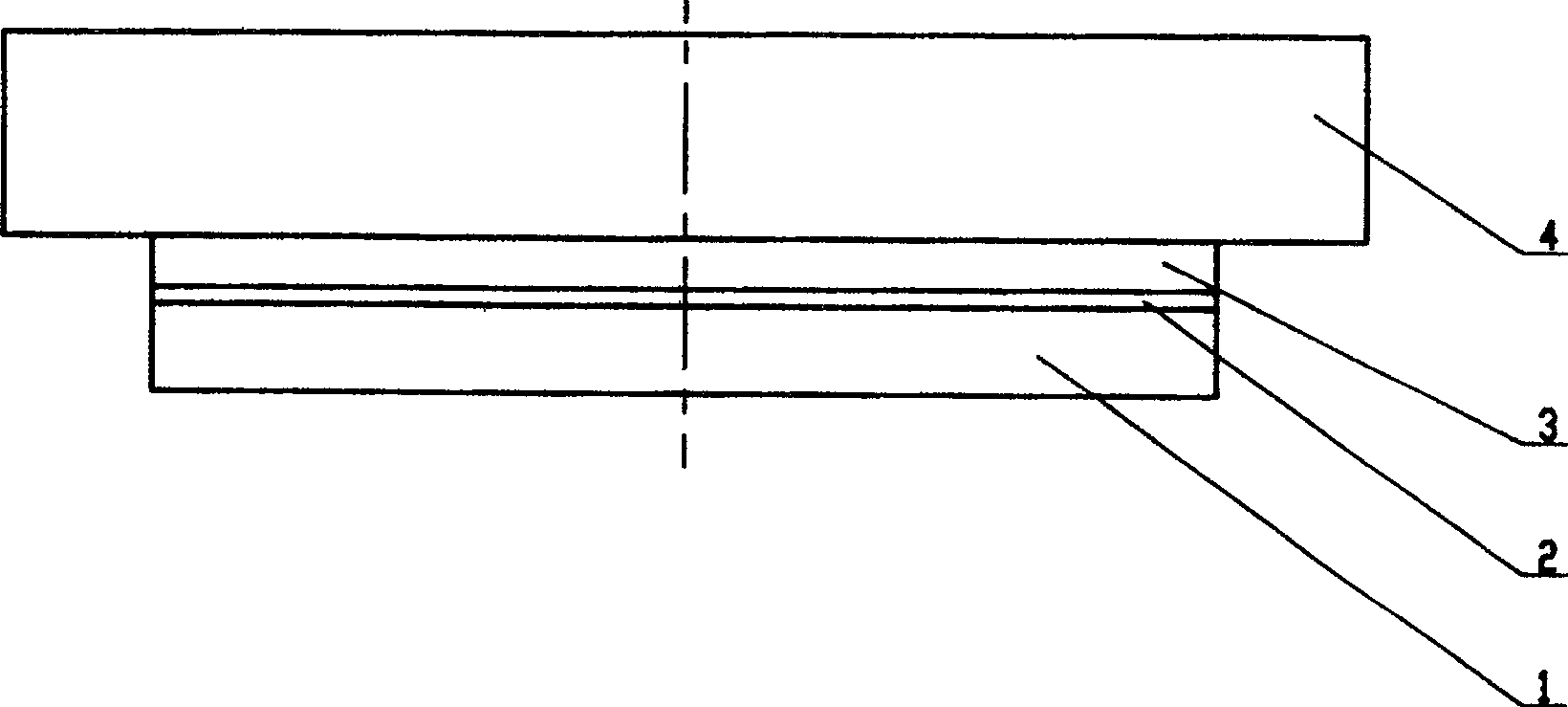

[0013] Example 1: Attached figure 1 Shown is a plate-type electric heating device - an electric hot plate. The heat transfer element 1, the electric heating film 2, and the heat insulating element 3 of the installation model are overlapped and fastened to the hot plate support of the vulcanizer—the pallet 4 by means of screws.

Embodiment 2

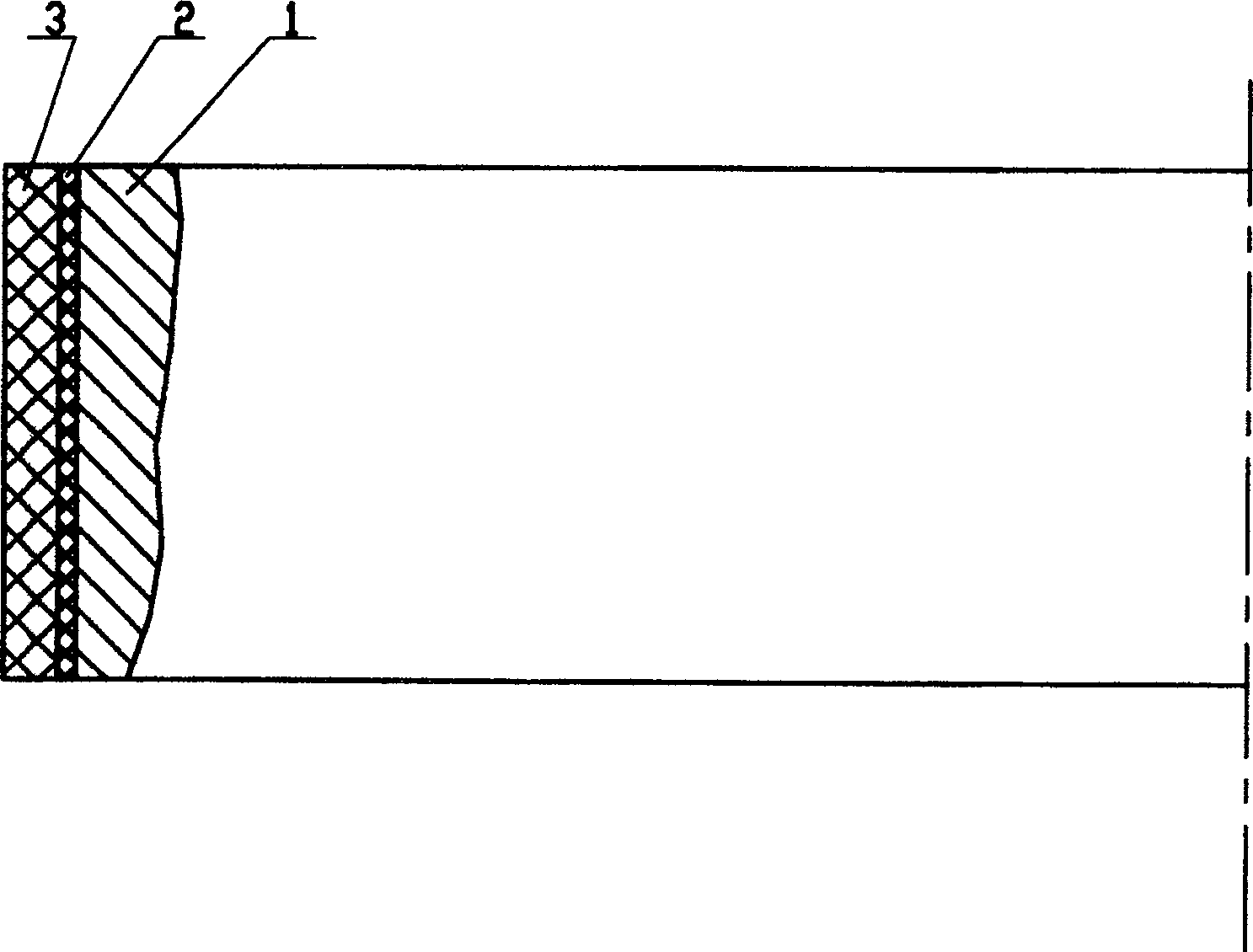

[0014] Example 2: Attached figure 2 Shown is the jacket type electric heating device - electric heating jacket. At this time, the heat transfer element 1 of the installation model is the guide ring of the tire vulcanization flexible mold, the electric heating film 2 is close to the outside of the guide ring, and the heat insulating element 3 tightly surrounds the electric heating film 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com