High frequency source electric heating heat setting roller

An electric heating and heat setting technology, which is applied in the field of textile machinery, can solve problems such as difficult maintenance, damage to heat setting rollers, and poor safety, and achieve good process applicability, high temperature adjustment accuracy, and small surface temperature difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

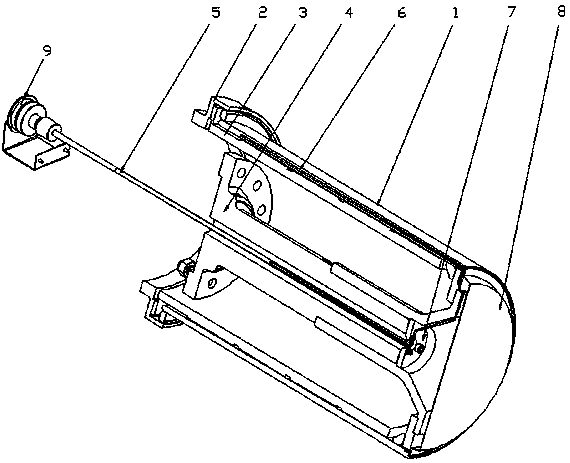

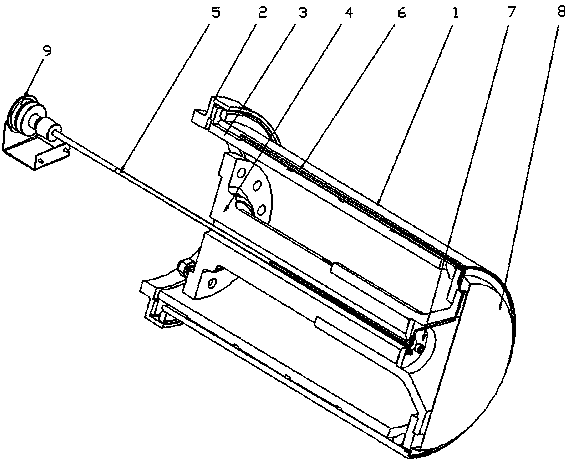

[0015] Such as figure 1 As shown, a high-frequency source electric heating heat setting roller includes a roller 1, a fixed sleeve 2, a heating coil 3, a spline shaft 4, a thermometer 6 and an inner end cover 7, and one end of the roller 1 is provided with an outer end Cover 8, the other end of the roller 1 is fixedly installed on the fixed sleeve 2, and the fixed sleeve 2 is fixed on the frame; the spline shaft 4 is arranged at the axis center of the roller 1, and one end of the spline shaft 4 passes through It is fixedly connected with the external hollow drive shaft, and the other end of the spline shaft 4 is fixedly connected with the roller 1 and axially fixed by the inner end cover 7; the heating coil 3 is set in the roller 1, and the side wall of the roller 1 An axial temperature measuring hole is provided, and the thermometer 6 is arranged in the temperature measuring hole;

[0016] In this embodiment, the spline shaft 4 is a hollow spline shaft, and a through hole is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com