Precise temperature adjustment system and its control method

A technology of temperature regulation and control method, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve problems such as it is difficult to meet the uniform control requirements of panel surface temperature, liquid crystal panel damage, etc., to achieve automatic control , Improve the accuracy of temperature regulation and avoid the effect of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

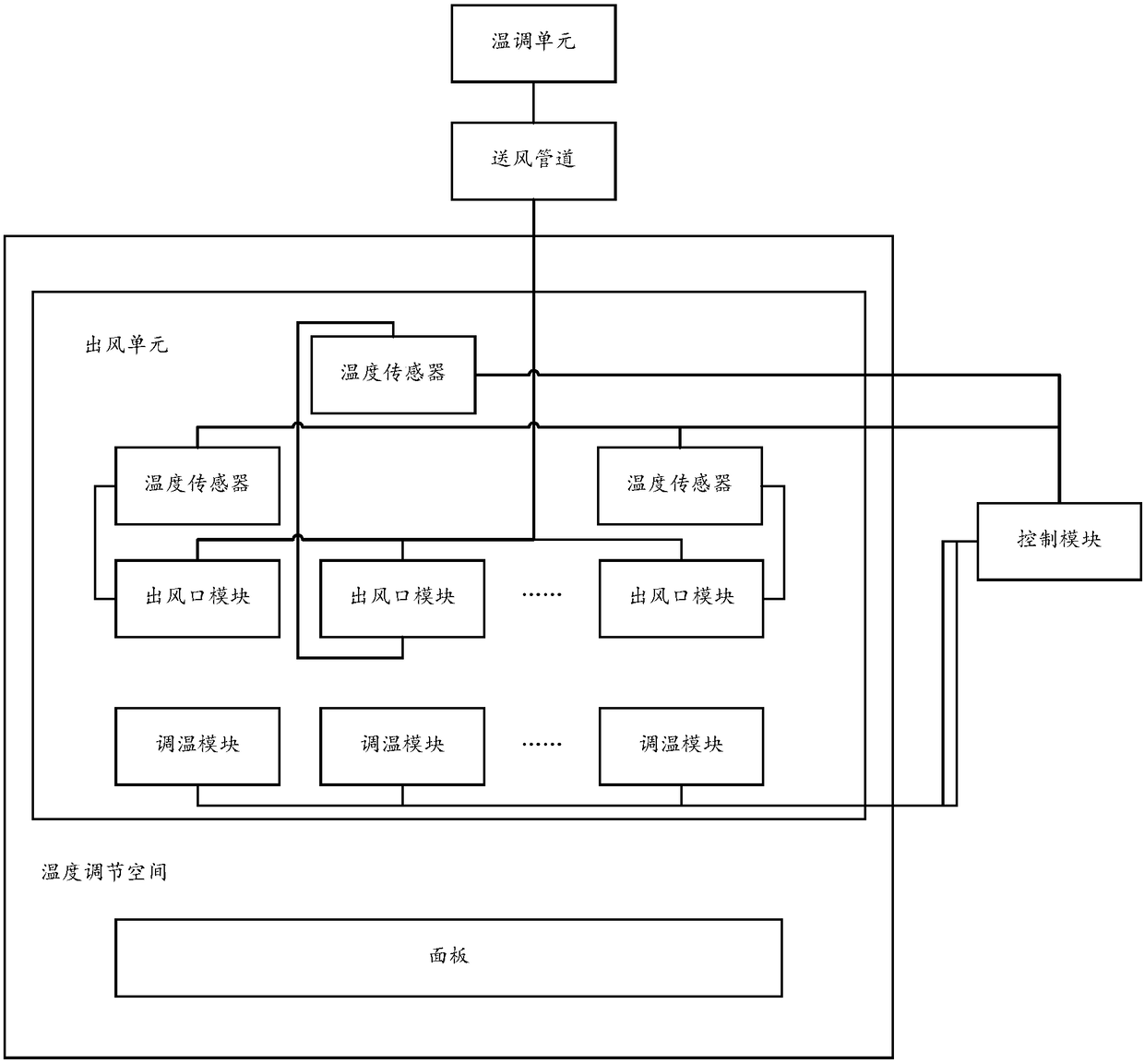

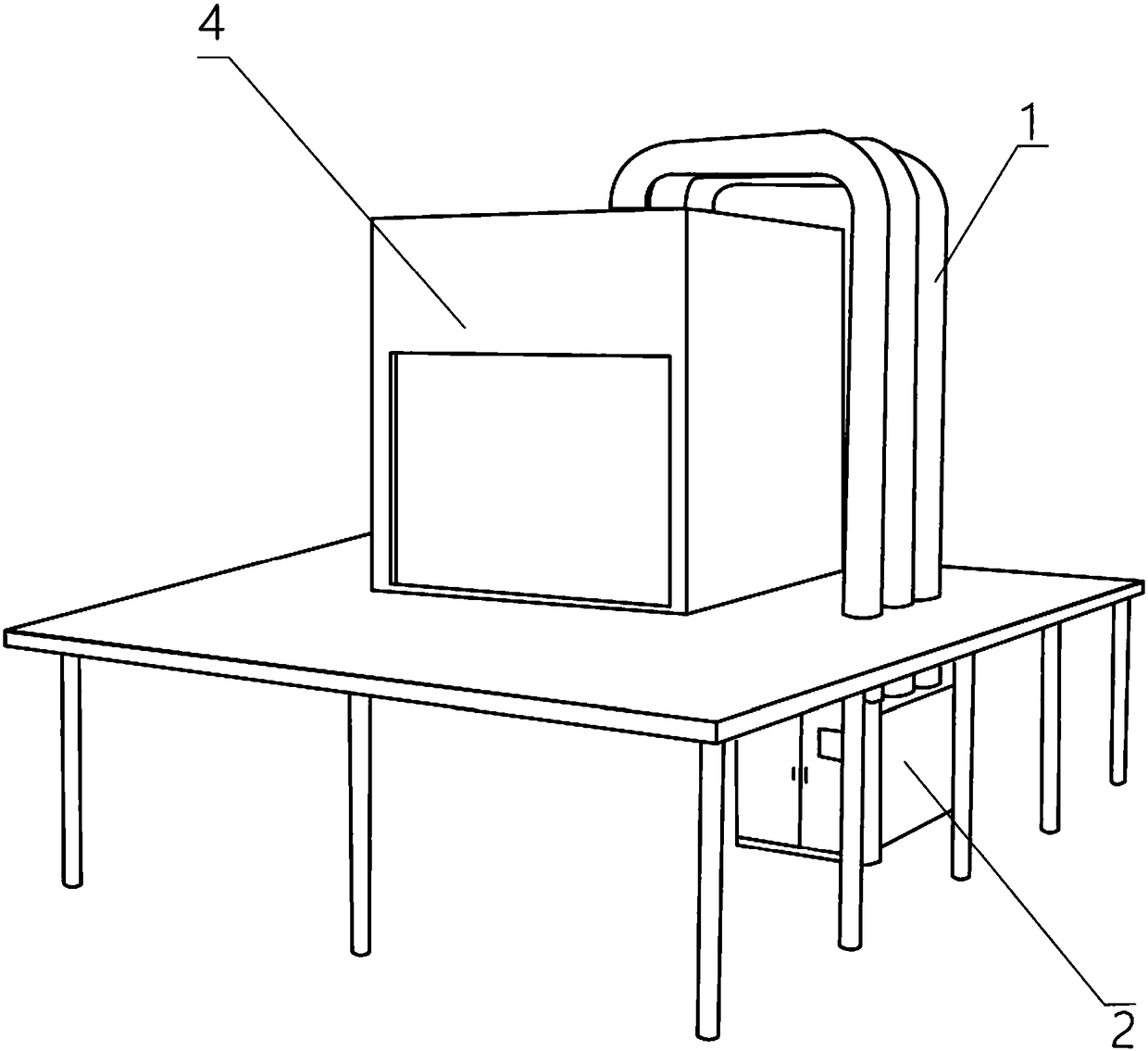

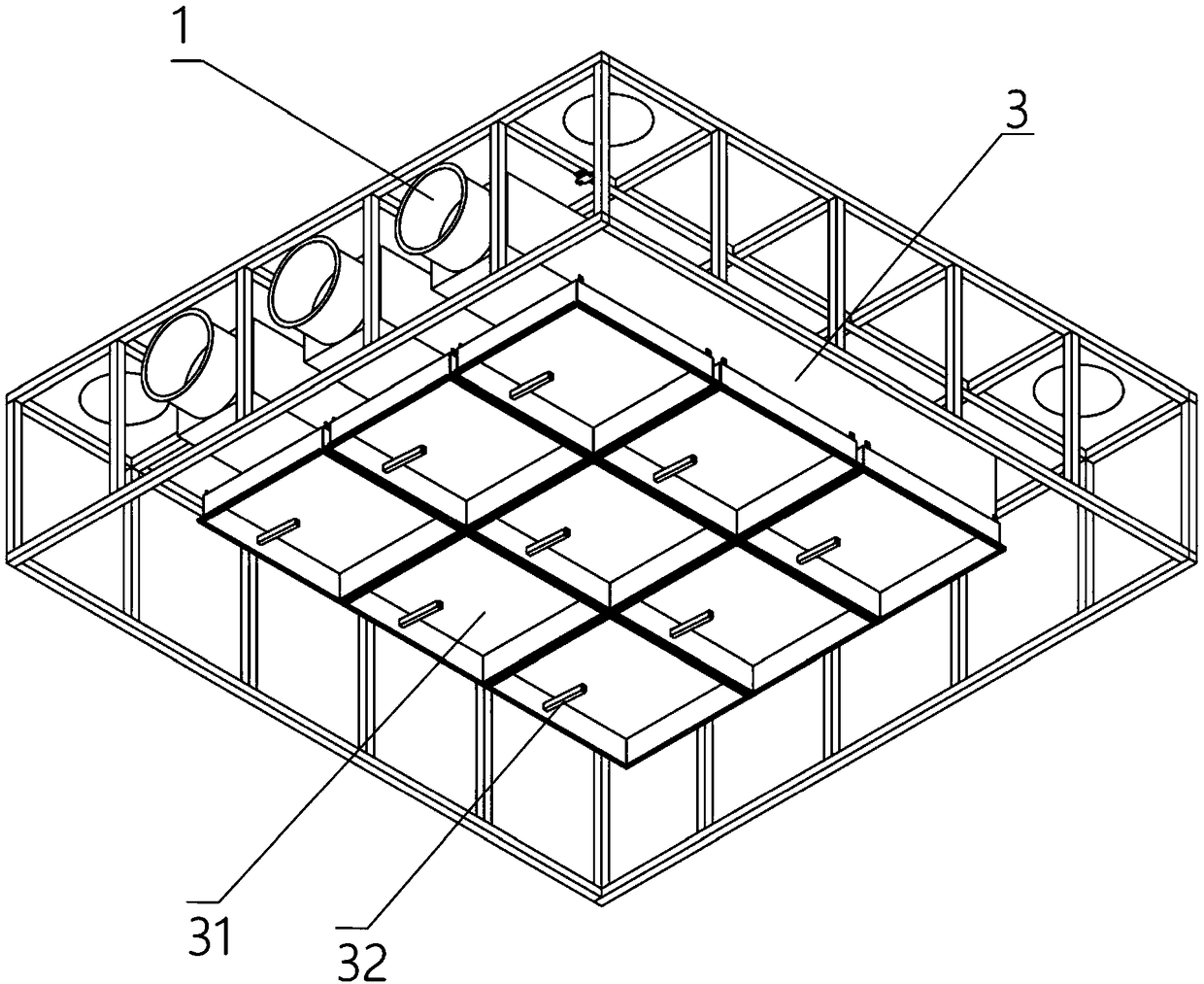

[0031] The first embodiment of the present invention provides a precision temperature regulation system for temperature regulation of the panels arranged in the temperature regulation space 4, see figure 1 , figure 2 , image 3 and Figure 4 Combined with the shown, it includes: a control module, a temperature adjustment unit 2, an air outlet unit 3 arranged in the temperature adjustment space 4, and an air supply pipe 1 connected between the temperature adjustment unit 2 and the air outlet unit 3; After the unit 2 has adjusted the temperature, it is sent out to the air outlet unit 3 through the air supply duct 1; the air outlet unit 3 includes: N air outlet modules 31 arranged opposite to the panel in an array, and N is a natural number greater than or equal to 2 A plurality of temperature sensors 32 are used to detect the air outlet temperature at the air outlet module 31; a plurality of temperature regulation modules 33 are used to regulate the temperature of the gas blo...

Embodiment approach 2

[0043] The second embodiment of the present invention provides a precision temperature regulation system, and the second embodiment is a further improvement of the first embodiment; the main improvement is that, in the second embodiment of the present invention, see Figure 5 As shown, the temperature adjustment unit 2 is also communicatively connected with the control module, and the control module is also used to control the output of the temperature adjustment unit 2 .

[0044] The output of the temperature adjustment unit 2 is controlled by means of the control module, so that the windows for temperature control can be concentrated, which is more convenient. Moreover, the temperature control unit 2 with temperature control can also obtain the desired temperature more conveniently.

Embodiment approach 3

[0046] The third embodiment of the present invention provides a precision temperature regulation system, and the third embodiment is a further improvement of the first or second embodiment; the main improvement is that in the third embodiment of the present invention, see Figure 6 and Figure 7 As shown, the precise temperature adjustment system further includes: a return air duct 5 connected between the temperature adjustment space 4 and the temperature adjustment unit 2 , and the gas in the temperature adjustment space 4 is transported to the temperature adjustment unit 2 through the return air duct 5 .

[0047] Using the return air acquired by the return air duct 5 to obtain the preset outlet air temperature can more easily obtain the required temperature than using the fresh air at ambient temperature, thereby shortening the heating time.

[0048] In this embodiment, the temperature adjustment unit 2 includes a cooler for cooling the gas delivered through the return air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com