High-temperature fuel servo flow metering characteristic test system

A characteristic test and flow measurement technology, which is applied in the direction of fluid pressure actuation system test, servo motor assembly, control/regulation system, etc., can solve the problems of high temperature regulation of unfueled medium, energy waste, etc., and achieve high energy utilization rate, The effect of wide temperature adjustment range and high temperature adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

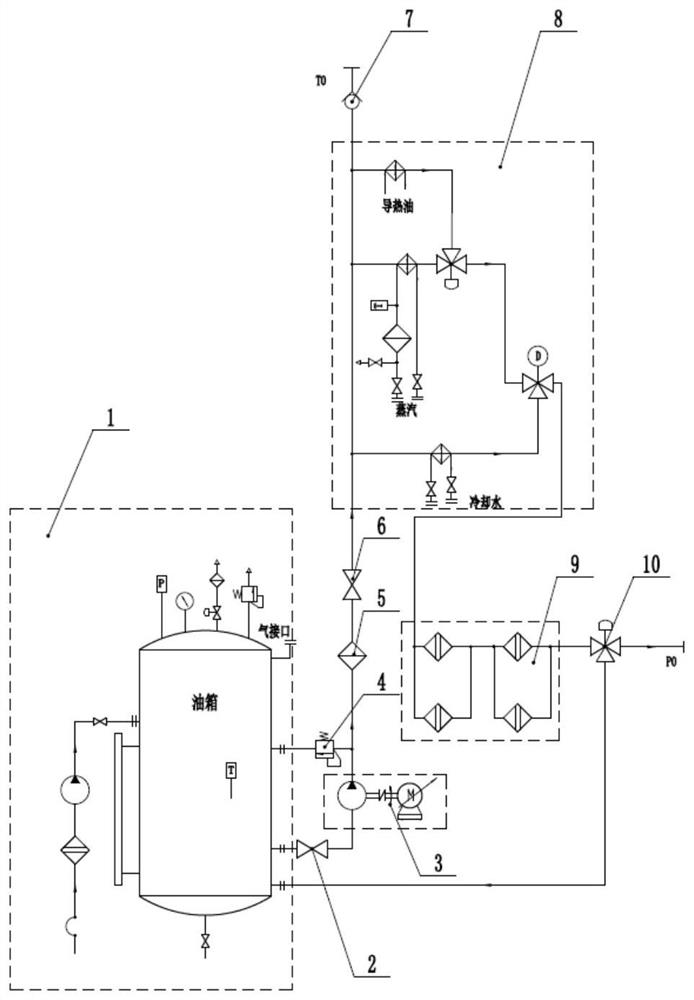

[0023] to combine Figure 1-Figure 6 , a high-temperature fuel servo flow metering characteristic test system of this embodiment is composed of a fuel power source, a fuel test system and a hydraulic load simulation system.

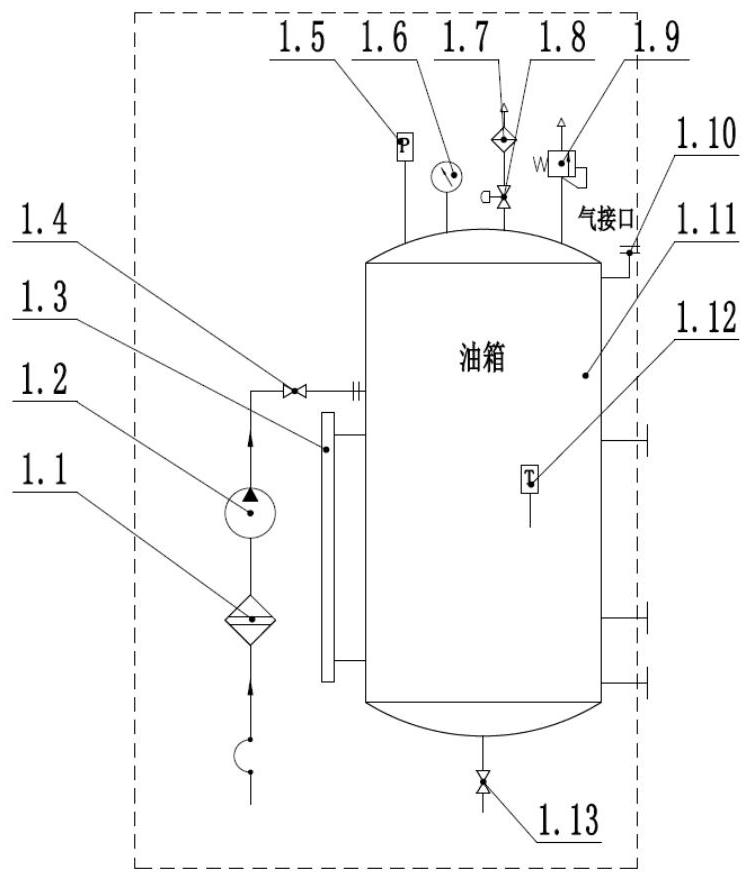

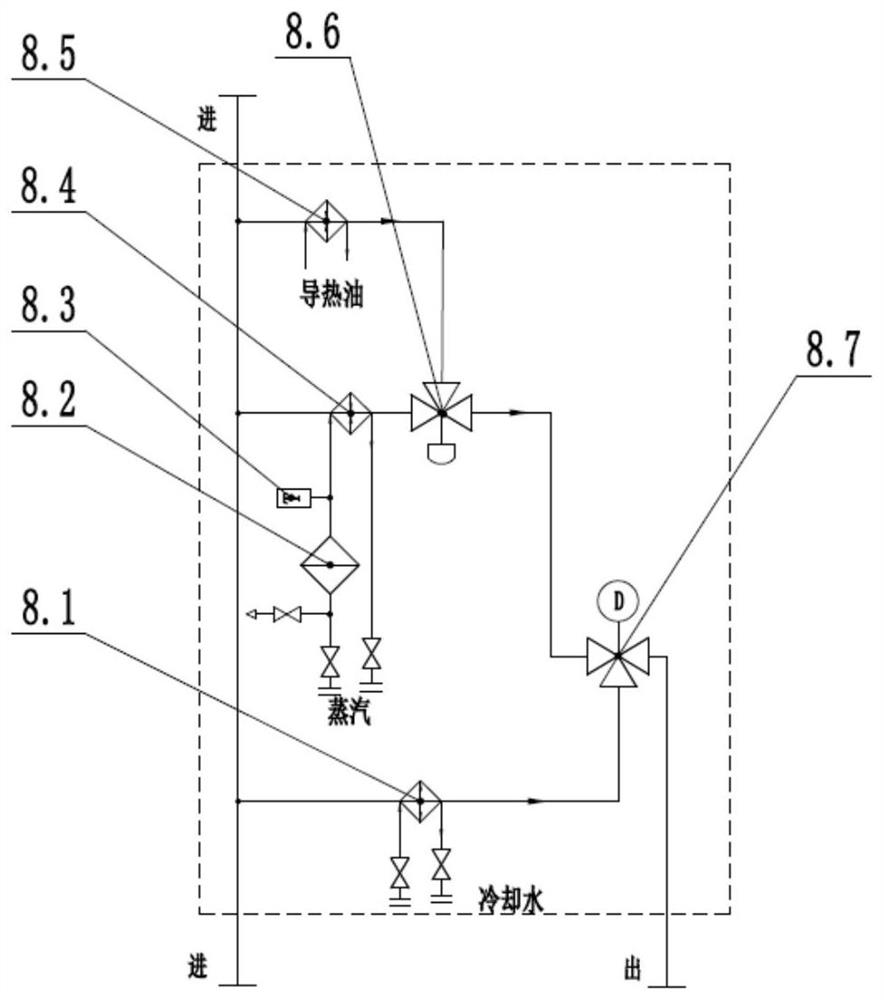

[0024] figure 1 It is the schematic diagram of the fuel power source system. The fuel is extracted from the fuel tank 1 through the shut-off valve 2 by the fuel pump motor unit 3, and then enters the oil temperature adjustment system 8 through the filter 5 and the shut-off valve 6. Fine filtration, the finely filtered oil can be controlled by the pneumatic three-way valve 10 to enter the main oil circuit P0 or enter the fuel tank 1. At the same time, an overflow valve 4 is provided behind the outlet of the motor pump unit 3 to communicate with the fuel tank 1; the return oil T0 of the fuel test system can enter the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com