Instrument for measuring low-temperature performance of road gap-grouting material

A technology for joint filling materials and low-temperature performance, which is applied in the field of temperature measurement devices for road joint filling materials, and achieves the effects of continuously adjustable temperature, simple and effective low-temperature extension performance, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

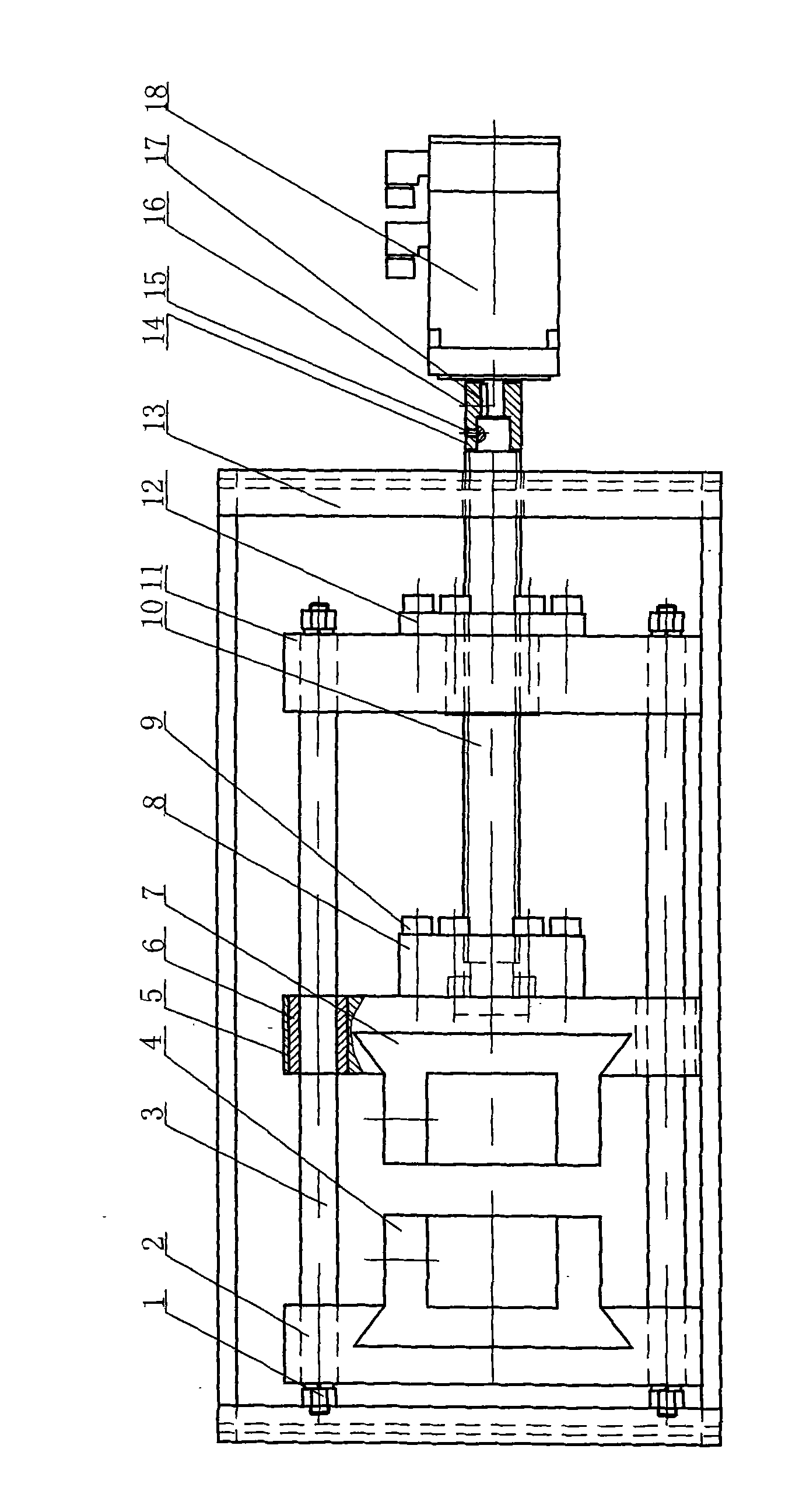

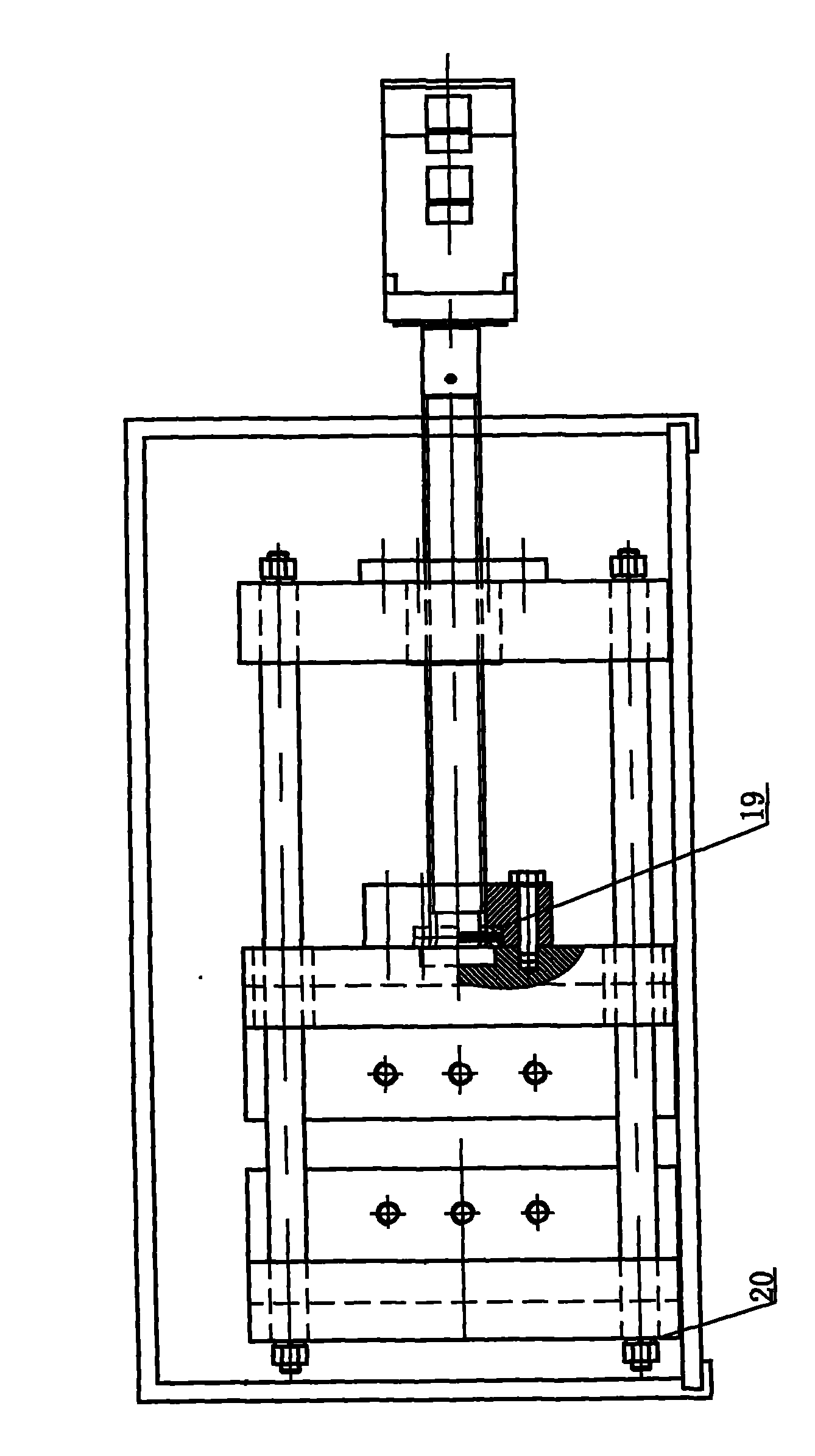

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

[0018] 1. Instrument composition

[0019] The measuring instrument in this embodiment is mainly composed of three parts: a bracket, a motor drive, and a temperature control. Wherein, the bracket part is mainly composed of a frame, a first support component 2, a second support component 5, and a third support component 11, and the material is Q235. The motor transmission part is mainly composed of screw 10, nut 12, coupling 14, AC servo motor 18, first fastening screw 15, second fastening screw 16 and other components, and the self-made material of the screw and coupling is Q235 , Nuts and fastening screws are standard parts, see the general assembly plan for the standard. The temperature control part is composed of a temperature control box 13 and a temperature measuring instrument, wherein the material of the temperature control box is plexiglass.

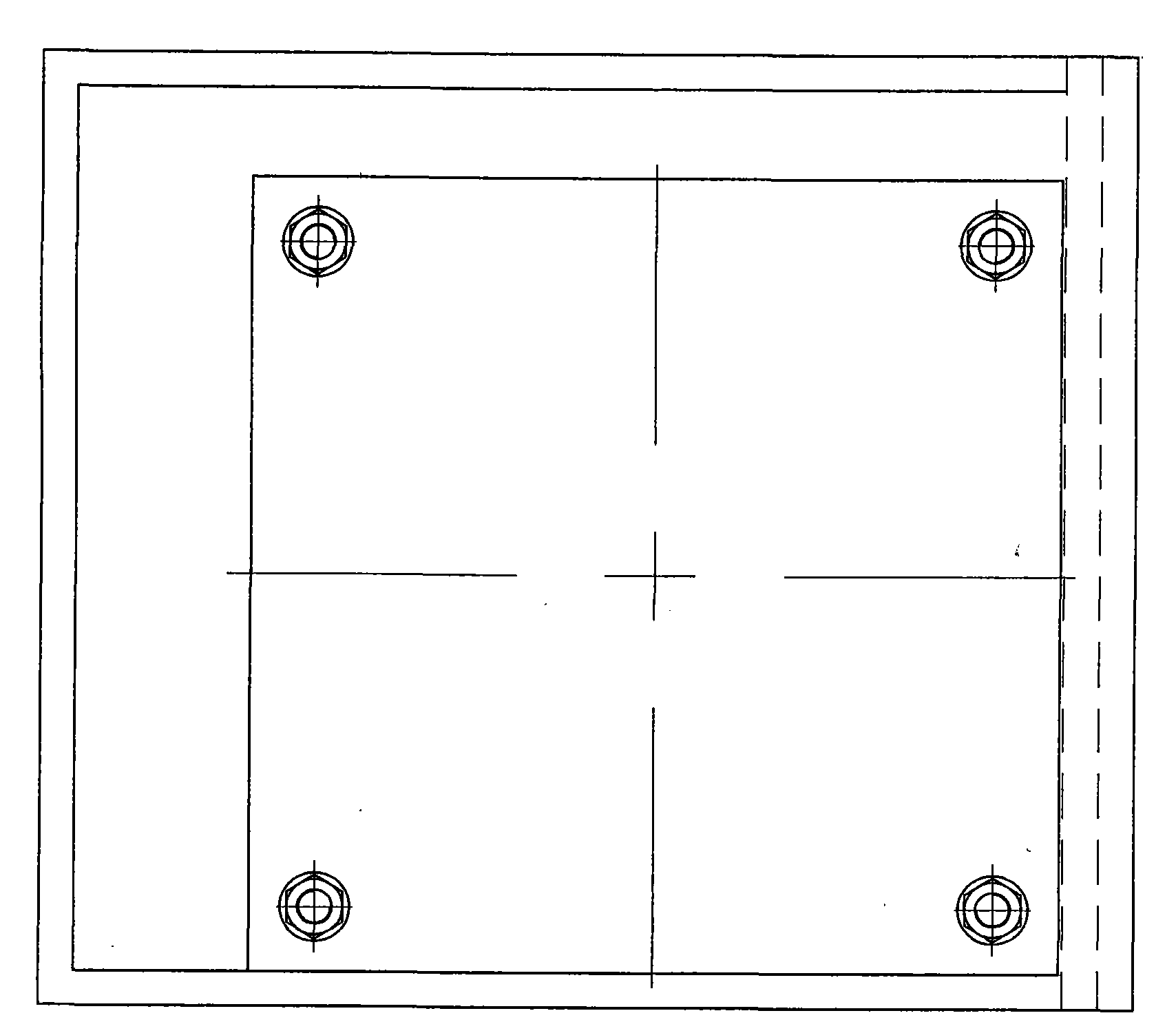

[0020] 2. Shape

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com