A kind of preparation method of thickness-controllable nanoporous metal film

A nanoporous, metal thin film technology, applied in nanotechnology, metal material coating technology, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficulty in preparing thin films with controllable thickness, and achieve precise thickness control, convenient disassembly, assembly and disassembly, etc. Uniform effect of alloy material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

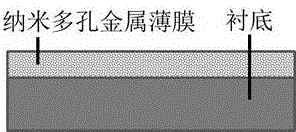

Image

Examples

Embodiment 1

[0021] (1) Make a hollow Zn metal sheet and a complete Ag metal sheet, place the hollow Zn sheet on the Ag sheet, and combine the two metal sheets as a target for pulsed laser deposition;

[0022] (2) Deposit a layer of Ag-Zn alloy thin film on the substrate by pulse laser deposition method, and the vacuum degree in the laser pulse cavity is 10 -4 Pa, when the film is deposited, the substrate temperature is 200 degrees Celsius, the laser frequency is 8Hz, the laser energy is 300mj, and the number of pulsed lasers is 5000 times.

[0023] (3) Put the Ag-Zn alloy film into an annealing furnace and anneal at 250 degrees Celsius for 2 hours.

[0024] (4) Soak the annealed alloy film in 1wt% NaOH solution for 6 hours for dealloying to obtain Ag nanoporous metal film.

Embodiment 2

[0026] 1) Make hollowed-out Zn metal sheets, Ag metal sheets and complete Au metal sheets. The hollowed-out Zn sheet is placed on the hollowed-out Ag sheet, and the Au metal sheet is placed on the bottom layer. The three metal sheets are combined as targets for magnetron sputtering;

[0027] (2) Deposit a layer of Zn-Ag-Au alloy film on the substrate by pulsed laser deposition method, and the vacuum degree in the vacuum chamber is 10 -4 Pa, when the film is deposited, the substrate temperature is 300 degrees Celsius, the sputtering power is 20W, and the sputtering time is 0.5 hours.

[0028] (3) Put the Ag-Zn alloy film into an annealing furnace and anneal at 350 degrees Celsius for 4 hours.

[0029] (4) Soak the annealed alloy film in 1wt% NaOH solution for 12 hours for dealloying to obtain Ag-Au nanoporous metal film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com