Liquid cooling system capable of simultaneously adjusting liquid supply pressure, flow and liquid supply temperature

A liquid supply and pressure technology, which is applied in the field of liquid cooling systems that simultaneously adjust the liquid supply pressure, flow rate and liquid supply temperature, can solve the problem of difficulty in adjusting the liquid supply pressure, flow rate and temperature at the same time, and achieve high practical value and stable operation. Reliable, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

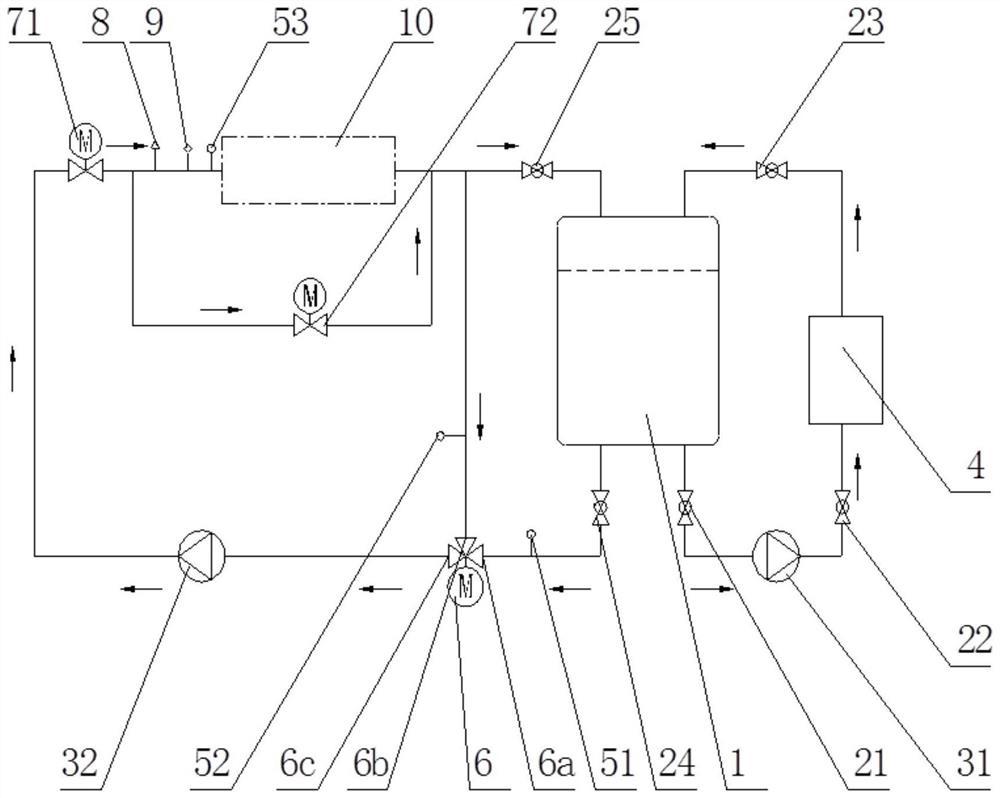

[0018] Such as figure 1 As shown, the present invention is a liquid cooling system that can simultaneously adjust the liquid supply pressure, flow rate and liquid supply temperature, including a liquid storage tank 1, a first ball valve 21, a first circulation pump 31, a second ball valve 22, and a cooling unit 4. The third ball valve 23 , the fourth ball valve 24 , the electric three-way valve 6 , the second circulation pump 32 , the first electric two-way valve 71 , the second electric two-way valve 72 , the load device 10 and the fifth ball valve 25 . in:

[0019] A liquid outlet of the liquid storage tank 1 is connected to the inlet end of the first ball valve 21 through a pipeline, the outlet end of the first ball valve 21 is connected to the inlet end of the first circulation pump 31 through a pipeline, and the outlet end of the first circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com