Heating method of vibrator and vibrator for implementing the method

A heating method and vibrator technology, applied in the field of vibrator heating and vibrator, can solve the problems of easy cooling and solidification of grease, affecting heating effect, inconvenient operation, etc., and meet environmental protection requirements, easy operation and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

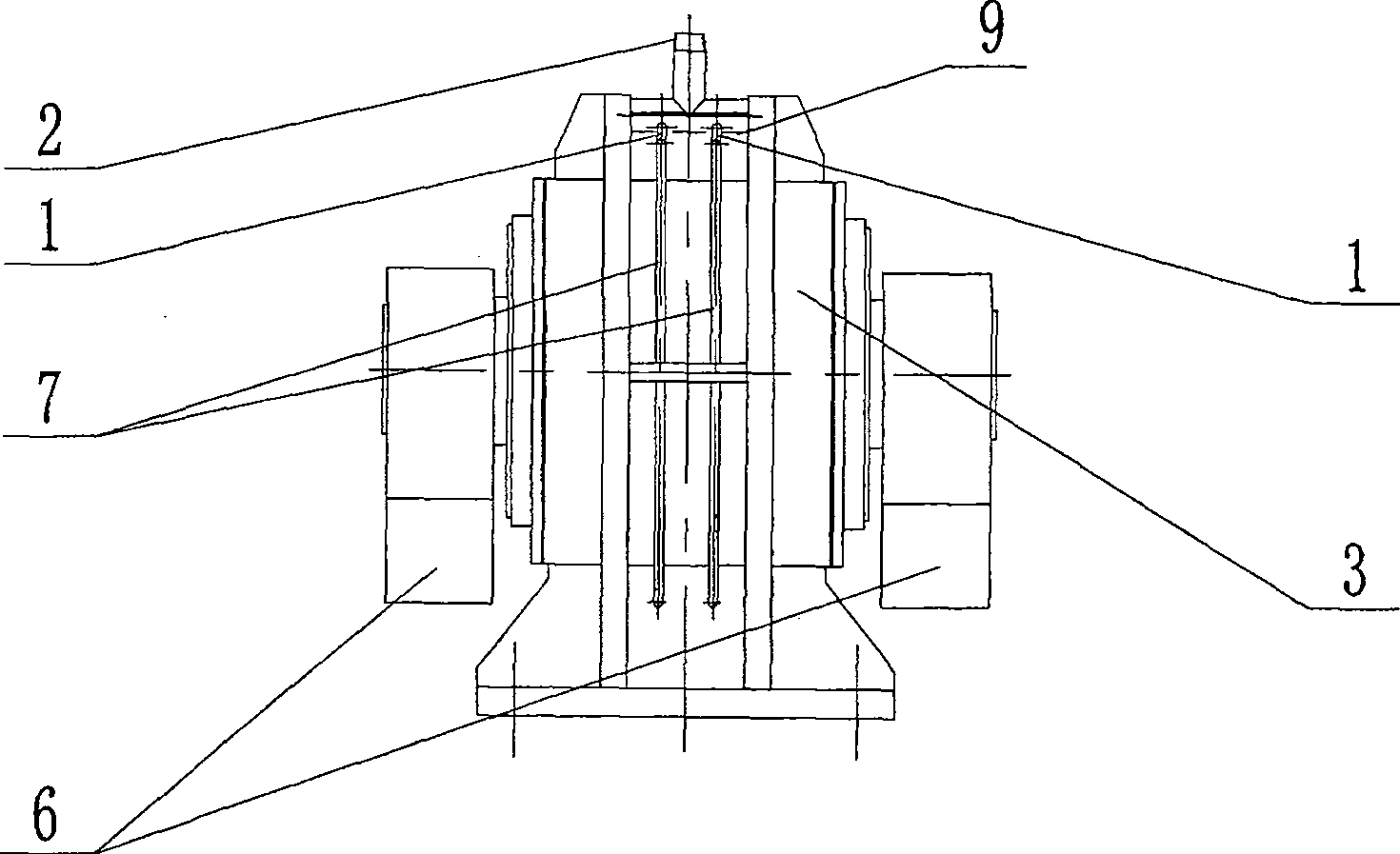

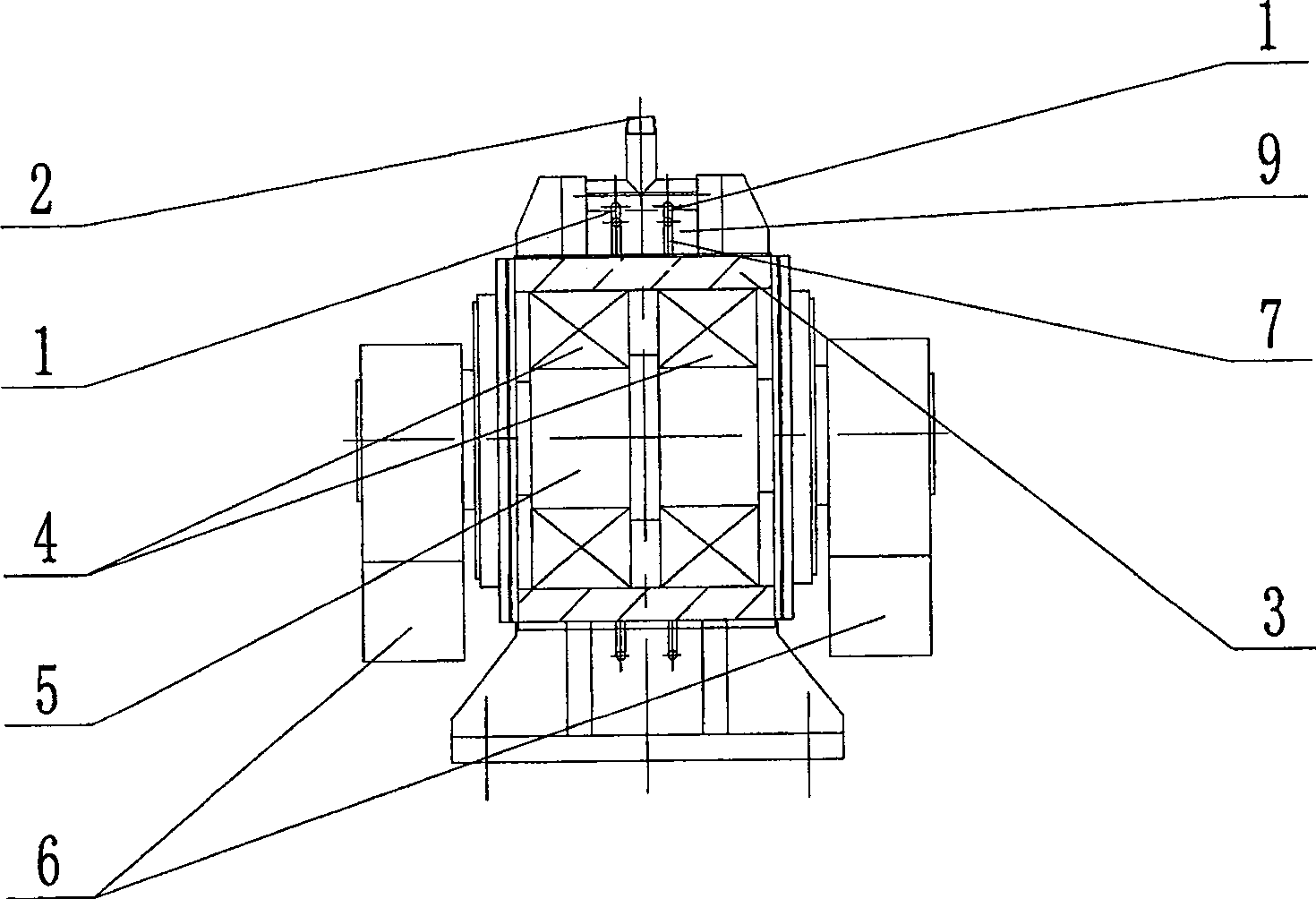

[0018] The heating method of the vibrator on the vibrating screen of the present invention is to transport steam to the bearing seat 3 of the vibrator through the steam pipeline 2, so that the steam is sprayed to the shell of the bearing seat 3, and the bearing seat 3 and the surrounding environment are heated. The temperature of the lubricating grease in the bearing housing 3 is increased by means of heat transfer, so that the viscosity of the lubricating grease is reduced, so as to facilitate the normal start of the vibrating screen.

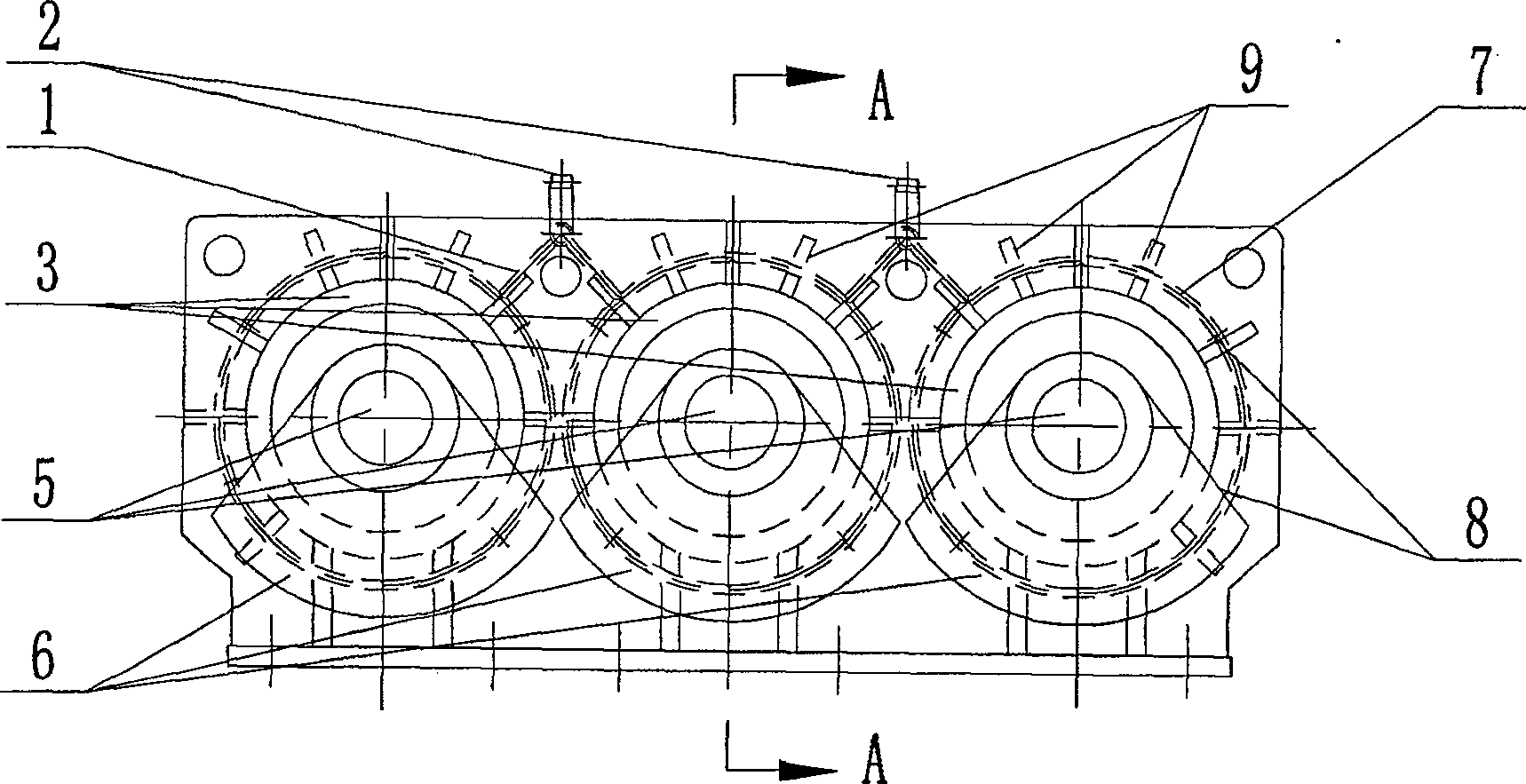

[0019] The vibrator for realizing the above-mentioned heating method of the present invention will be further described in detail below with the above-vibration three-axis vibrator as an example. Such as figure 1 , figure 2 and image 3 As shown, the vibrator of the present invention comprises three groups of bearing housings 3, bearings 4, vibration shafts 5 and eccentric bodies 6, bearings 4 are installed in bearing housings 3, vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com