Process for preparing high purity soy phoshatidylcholine without lysophosphatide

A technology of phosphatidylcholine and lysophospholipid, applied in the field of phospholipids, can solve the problems of inability to realize industrialized production, inability to remove lysophospholipids and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

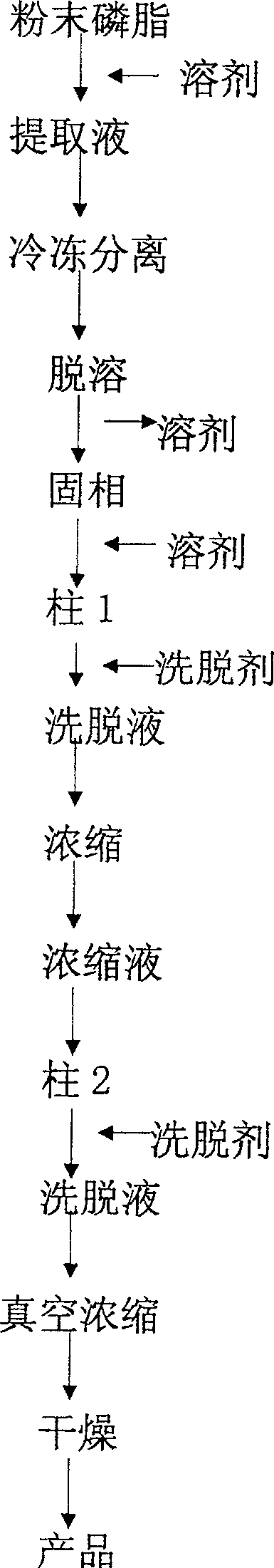

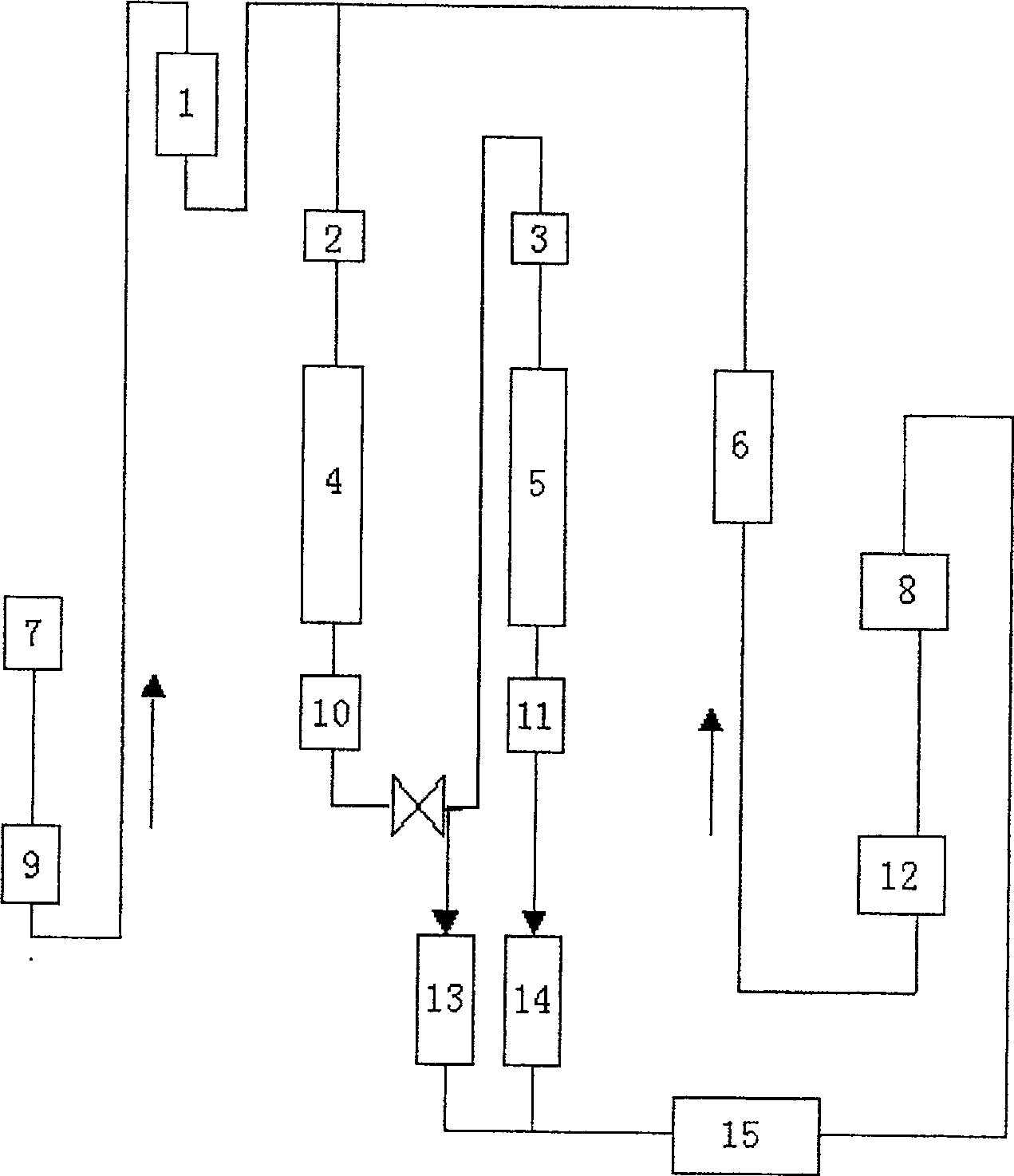

Method used

Image

Examples

Embodiment 1

[0019] Add 100 grams of powdered phospholipids to 300 milliliters of 95% ethanol, stir and leach for half an hour at room temperature, take the supernatant and let stand at -5°C for 24 hours, filter, and remove ethanol. Prepare an ethanol solution with a solid mass concentration of 2%, pass through an aluminum oxide column, and elute with 95% ethanol at 45°C. % ethanol was eluted, and the eluent was further vacuum-dried to obtain 7.5 g of the product after vacuum precipitation.

[0020] Table 1: Product indicators obtained by this method

[0021] Acid value (mg / g) Iodine value (g / 100g) Phosphorus content% Phosphatidylcholine content% Lysophospholipid content% 8.7 97.2 3.92 93.4 -

Embodiment 2

[0023] Add 100 grams of powdered phospholipids to 700 milliliters of 80% methanol, stir and leach for half an hour at room temperature, take the supernatant and concentrate to half of the original volume, stand at -6°C for 20 hours, filter, and remove methanol. Prepare a methanol solution with a solid mass concentration of 2%, pass through a manganese dioxide column, and elute with 80% methanol at 20°C. After concentrating the eluent 10 times, pass through a diatomite column, 80% ethanol was eluted, and the eluent was further vacuum-dried after vacuum precipitation to obtain 9.2 g of the product.

Embodiment 3

[0025] Add 100 grams of powdered phospholipids to 1100 milliliters of 90% propanol, stir and leach for half an hour at room temperature, take the supernatant and concentrate to one-third of the original volume, stand at -8°C for 15 hours, filter, and remove the solvent. Prepare a propanol solution with a solid mass concentration of 2%, pass through an aluminum oxide column, and elute with 90% propanol at 50°C. It was eluted with 90% propanol at °C, and the eluent was vacuum-precipitated and further vacuum-dried to obtain 4.7 g of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com