Continuous preparation method for polyether glycol

A polyether polyol and low-molecular-weight polyether technology, which is applied in the field of continuous preparation of polyether polyol, can solve the problems of long induction period, unstable quality index, and reduced weather resistance of polyurethane, and achieve the effect of a simple reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

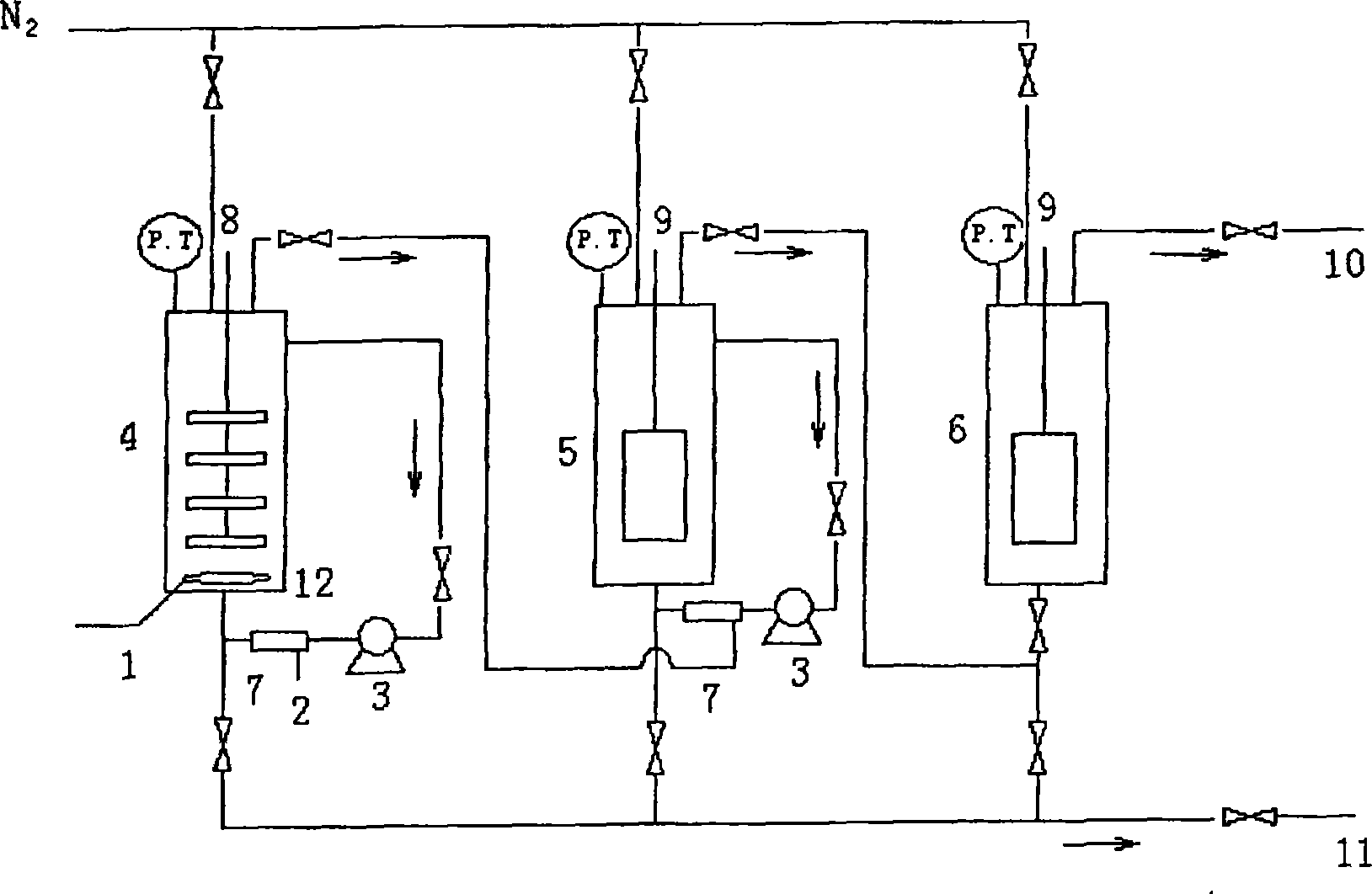

[0037] Preparation equipment and processes such as figure 1 As shown, get quantitative catalyst and evenly disperse in 0.5Kg low molecular weight polyalcohol N204 (two functionalities, hydroxyl value 350mgKOH / g), and add it to the small test reactor, vacuum with N 2 Replace 1-2 times, keep N 2 The pressure is 0.1MPa, heating, stirring, and raising the temperature to 135°C; a certain amount of catalyst is evenly dispersed in 4Kg of low molecular weight polyol N204, and then stored in a 5L storage tank. The reaction kettle is heated to 150°C, and a certain amount of propylene oxide (PO) is continuously pressed into the reaction kettle with nitrogen, and the induction is carried out when the pressure in the reaction kettle reaches 0.35MPa. When the temperature in the kettle rises and the pressure drops, the induction is successful. Open the external circulation and continue to feed PO into the continuous small kettle. When the total mass of PO introduced reached 2.6Kg, the feed...

Embodiment 2

[0039] Using the above-mentioned N2O4 as the initiator, the reaction process is the same as that in Example 1. After the system is stabilized, the temperature is lowered to 130°C for reaction. The hydroxyl value of the product obtained is 55.51mgKOH / g, the degree of unsaturation is 0.0033mmol / g, and the molecular weight distribution is 1.06.

Embodiment 3

[0041] Get quantitative catalyst and evenly disperse in 0.5Kg low-molecular-weight polyol N204 (two functionalities, hydroxyl value 350mgKOH / g), and add it to the small test reactor, vacuum with N 2 Replace 1-2 times, keep N 2 The pressure is 0.1MPa, heating, stirring, and raising the temperature to 135°C; a certain amount of catalyst is evenly dispersed in 2Kg of propylene glycol, and then stored in a 5L storage tank. The reaction kettle is heated to 170°C, and a certain amount of propylene oxide (PO) is continuously pressed into the reaction kettle with nitrogen, and the induction is carried out when the pressure in the reaction kettle reaches 0.35MPa. When the temperature in the kettle rises and the pressure drops, the induction is successful. Open the external circulation and continue to feed PO into the continuous small kettle. When the total mass of PO introduced reached 2.6Kg, the feed metering pump was turned on to pump PO and the aforementioned propylene glycol / catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com