Carbon deposit cleaning agent and its application in reproduction process of carbon deposit deactivation catalyst

A technology for deactivating catalysts and cleaning agents, which is used in catalyst regeneration/reactivation, chemical/physical process, physical/chemical process catalysts, etc., to reduce carbon deposits and reduce toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

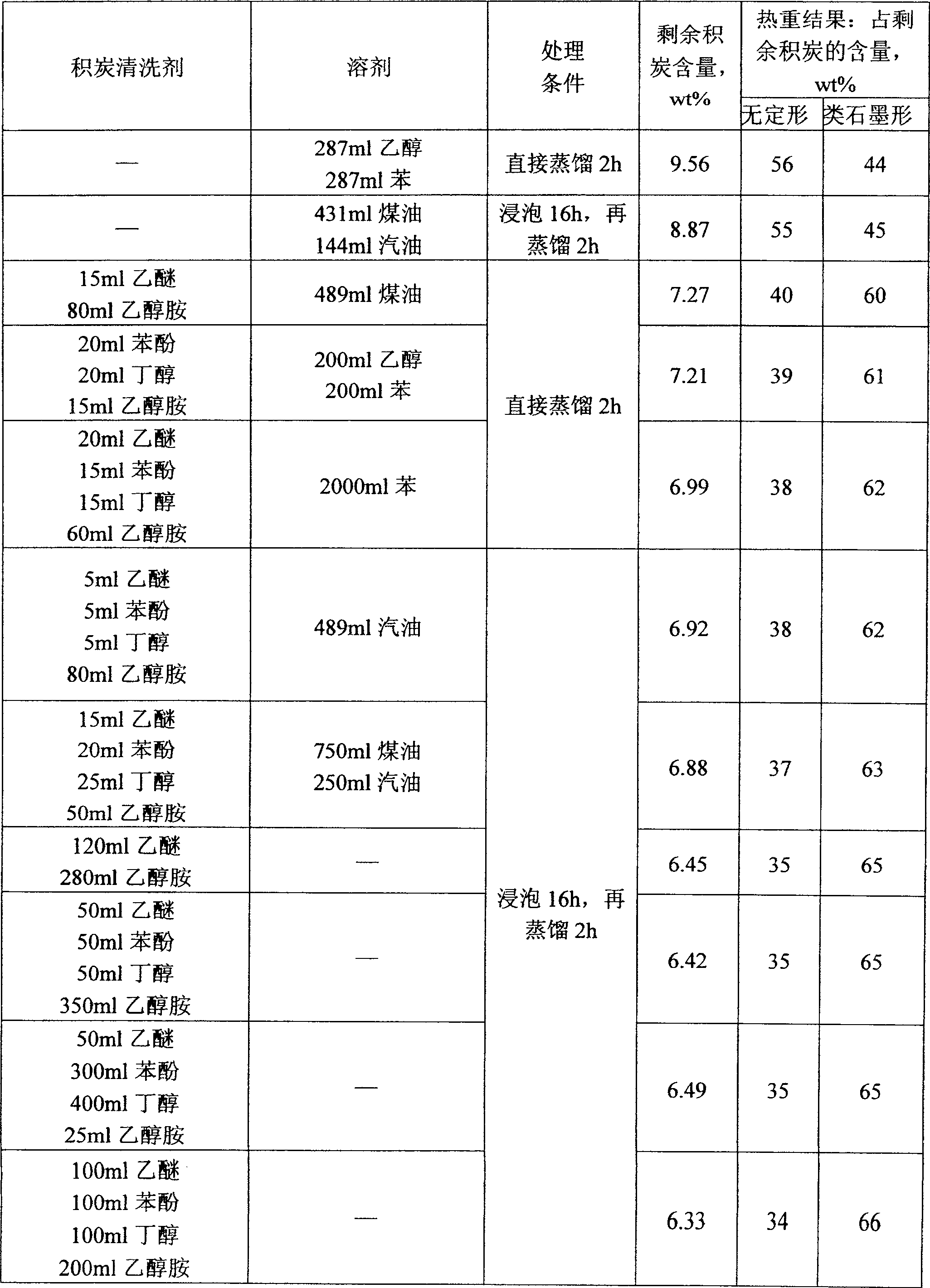

[0030] In a 1000ml flask, add different carbon deposit cleaning agents (see Table 1 for specific composition and content) to hydrodesulfurize MoNiP / Al 100ml deactivated residue after an industrial operation2 o 3 Catalyst (numbering is A, carbon deposition content is 11.45wt%) is processed respectively, and the catalyst after processing continues to process with dehydrated alcohol, measures the content change of amorphous and graphite-like shape carbon deposition with thermogravimeter then, its result sees Table 1.

[0031] Table 1 Hydrodesulfurization of residual oil MoNiP / Al 2 o 3 Change results of coke content of deactivated catalyst after treatment

[0032]

[0033] As can be seen from Table 1, compared with the deactivated catalyst that only ethanol and benzene or kerosene and gasoline are processed, with the catalyst that the carbon deposit cleaning agent solution of the present invention is processed, the amount of carbon deposits all significantly reduces, especial...

Embodiment 2

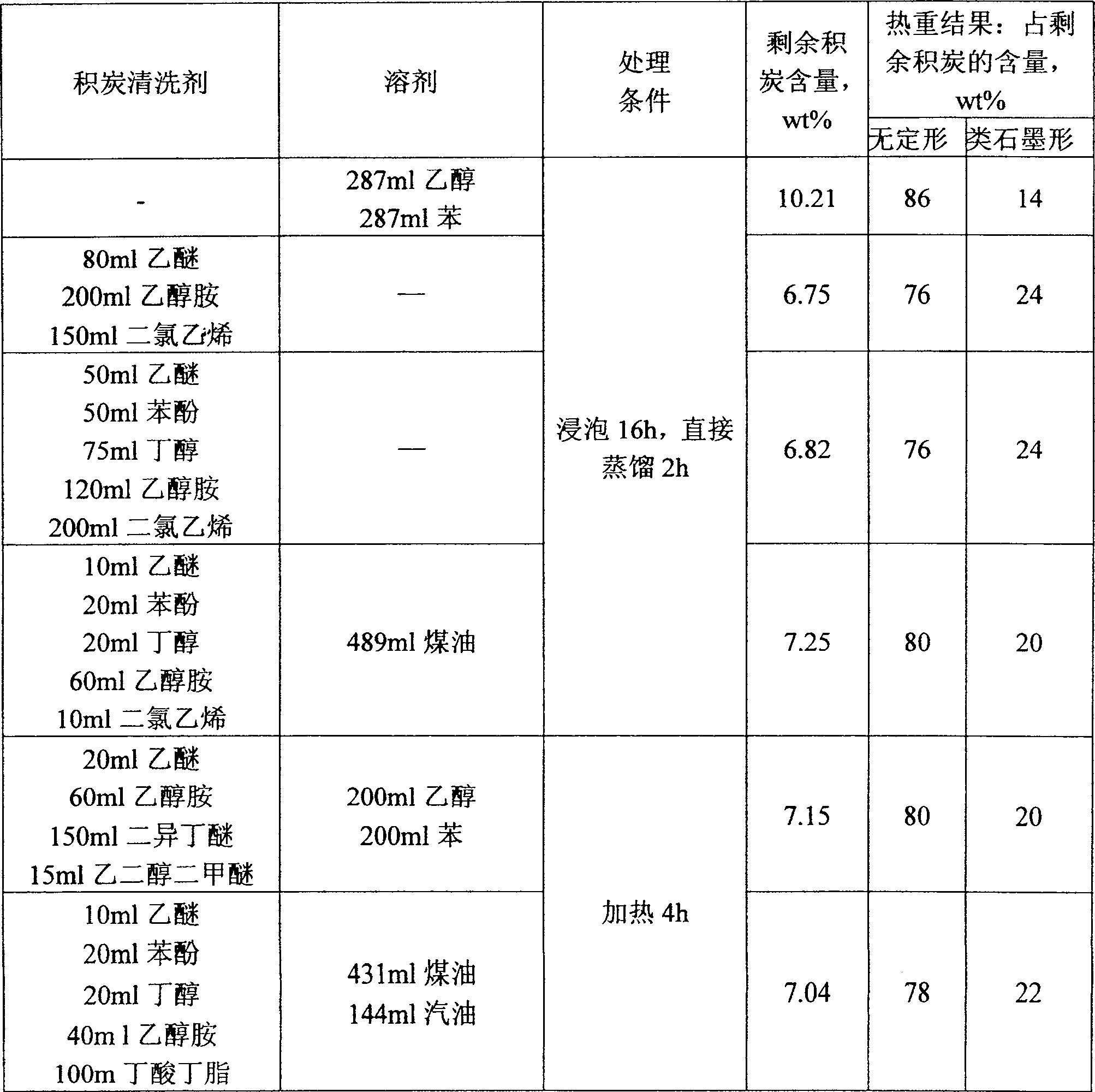

[0042] In the flask of 1000ml, add carbon deposit cleaning agent (concrete composition and content see Table 3) to the 100ml Mo / HZSM-5 methane aromatization catalyst (numbering is B, carbon deposit content is 10.84wt%) after an industrial operation After treatment, the treated catalyst was continued to be treated with absolute ethanol, and then the content change of amorphous and graphite-like carbon deposits was measured with a thermogravimeter. The results are shown in Table 3.

[0043] Table 3 Change results of coke content in methane aromatization Mo / HZSM-5 catalyst after treatment

[0044]

[0045] As can be seen from Table 3, the carbon deposit cleaning agent of the present invention contains other at least An organic substance, which is more conducive to reducing the carbon deposition on non-hydrogenation catalysts, especially has a special effect on the removal of amorphous structure carbon deposition.

[0046] The above-mentioned 100ml deactivated methane aromatiz...

Embodiment 3

[0054] 100ml hydrotreating MoNiP / Al after an industrial operation 2 o 3 Deactivated catalyst (coded as C, carbon deposit content is 10.21wt%) is regenerated in the following way:

[0055] First, the catalyst is loaded into the regeneration unit, and the N 2 The device is replaced, and then the oxygen content is adjusted to 2.0v%, and the catalyst is regenerated by burning charcoal step by step. The main control conditions at each stage are: 120°C, constant temperature for 3h; 200°C constant temperature for 2h; 300°C constant temperature for 1.5h; 500°C constant temperature for 3h.

[0056] The 15ml catalyst that regenerates like this is packed in microreactor, carry out activity evaluation according to following condition:

[0057] Raw oil: 950μg / g pyridine / kerosene; volumetric space velocity: 2.0h -1 ;Temperature: 360°C: Reaction pressure: 4.0MPa; Hydrogen flow rate: 100ml / min. Samples were taken for analysis after 12 hours of stabilization. The nitrogen content in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com