Yarn ear forming mechanism of mule spinning machine

A spinning frame and transmission mechanism technology, which is applied to spinning machines, spinning machines with intermittent winding, textiles and papermaking, etc. It can solve the problems of large forming errors, unpredictability, and cumbersome adjustment parameters, and achieve high accuracy. , intuitive adjustment, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

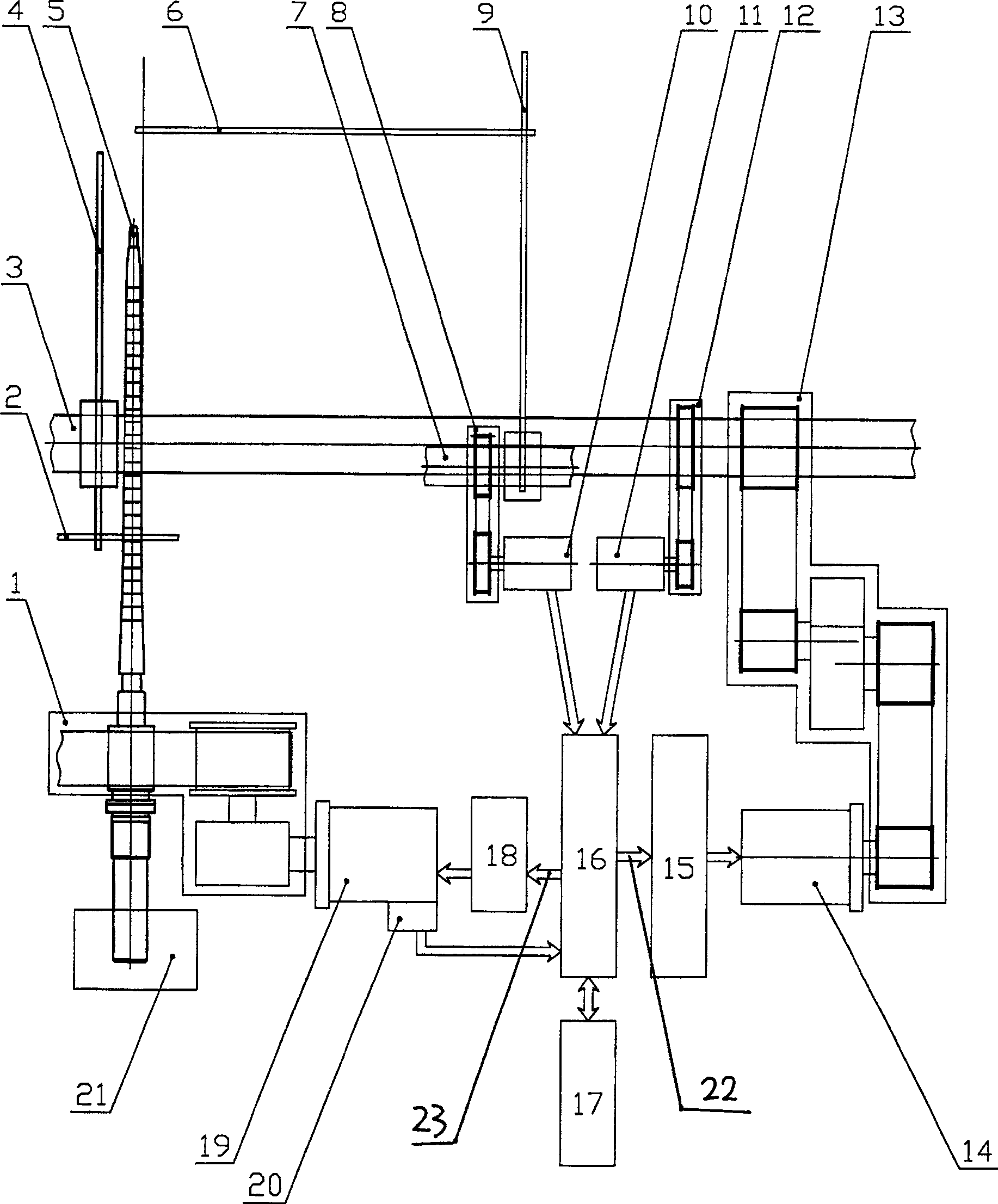

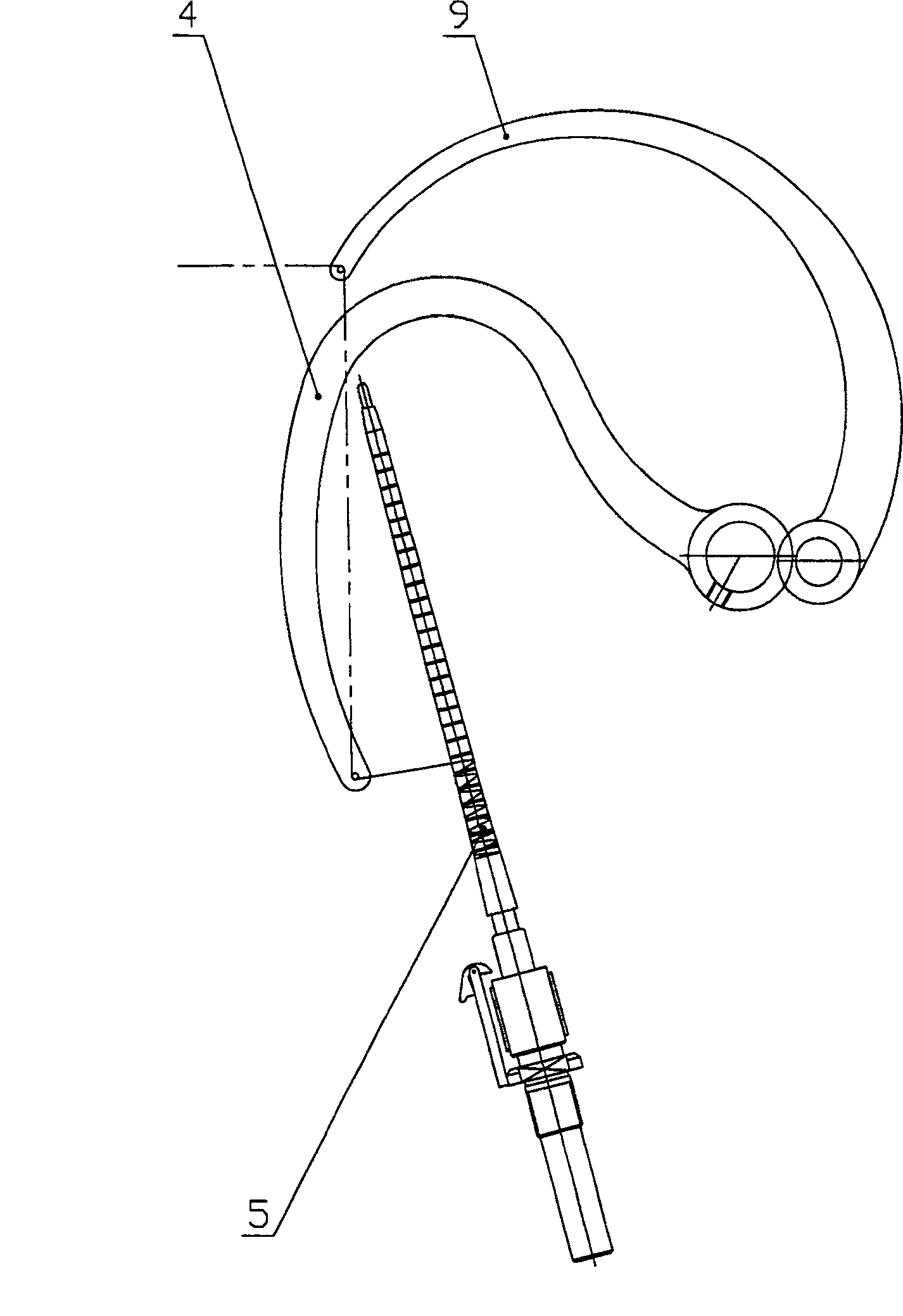

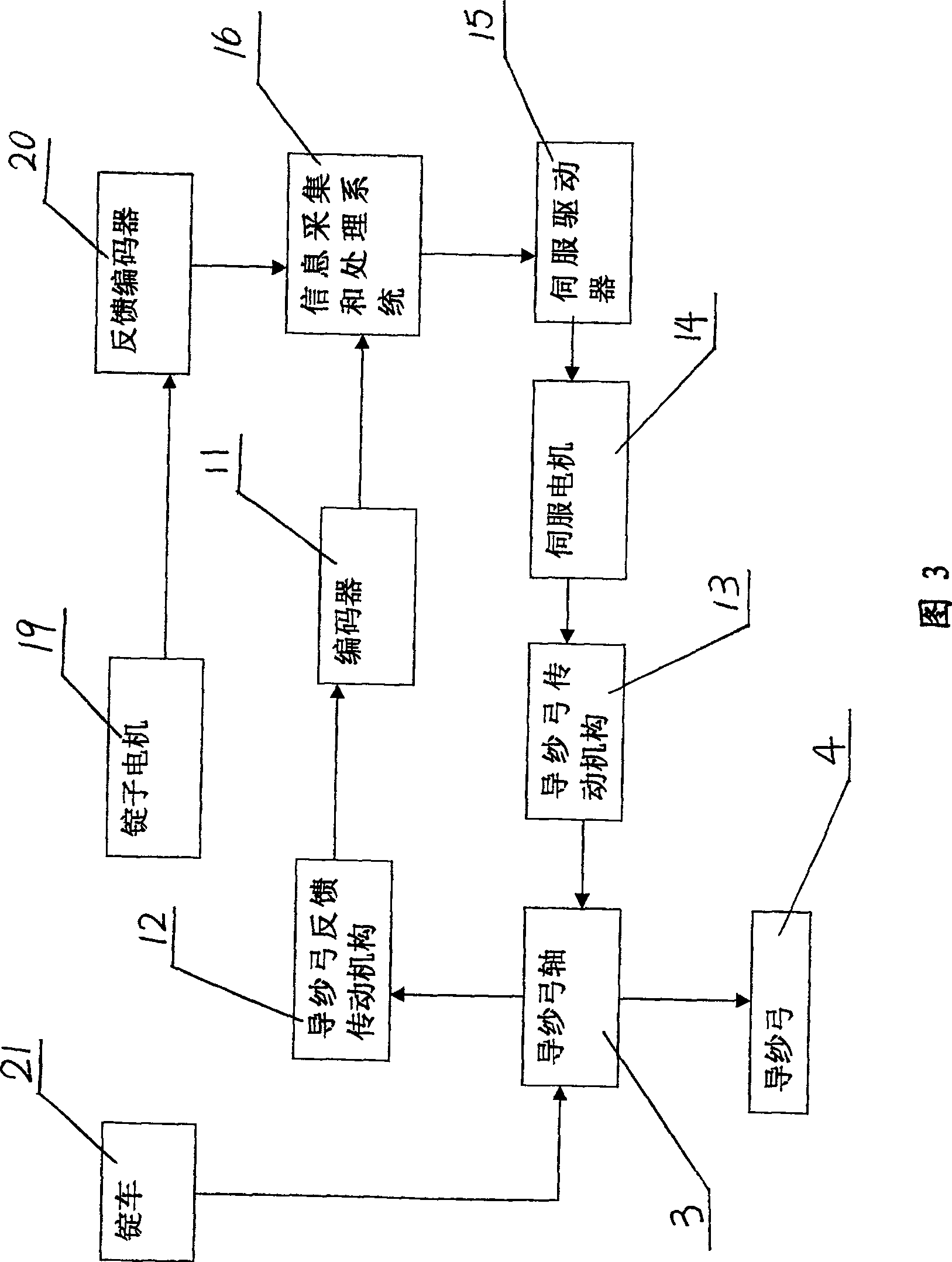

[0024] Such as Figure 1 ~ Figure 2 The yarn fringe forming mechanism of a mule spinning frame shown includes a control center, an information collection and processing system 16, consisting of a yarn guide shaft 3, a yarn guide 4, a yarn guide transmission mechanism 13, and a servo motor 14. , the guide bow transmission unit that servo driver 15 forms, the spindle transmission unit that is made up of spindle 5, spindle transmission mechanism 1, spindle motor 19, frequency converter 18, spindle car 21, tension bow 9, tension bow shaft 7.

[0025] Wherein, in the yarn guide transmission unit, the yarn guide 4 is fixed on the yarn guide shaft 3, and the output part of the yarn guide transmission mechanism 13 is connected with the yarn guide shaft 3 for driving the yarn guide shaft 3 to rotate , the input part of the yarn guiding bow transmission mechanism 13 is connected on the servo motor 14, that is to say the yarn guiding bow transmission mechanism 13 is driven by the servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com