Winding method of transformer coil

A transformer coil and winding method technology, applied in the field of transformers, can solve the problems of manual correction, such as difficulty in improving efficiency, difficulty in meeting requirements, and poor forming effect, so as to prevent leakage of fluid insulating materials, good forming effect, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

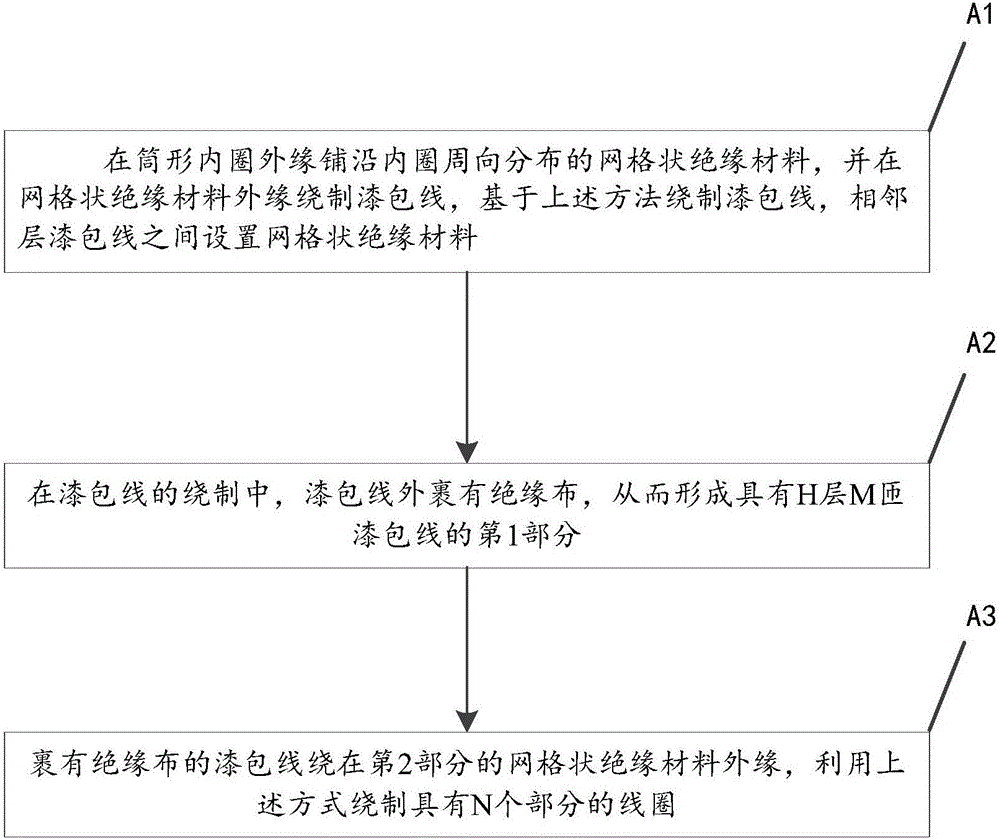

[0042] figure 1 A flow chart of a method for winding a transformer coil according to an embodiment of the present invention is schematically provided, as figure 1 As shown, the winding method of the transformer coil includes the following steps:

[0043] (A1) Lay a grid insulating material distributed along the circumferential direction of the inner ring on the outer edge of the cylindrical inner ring, and wind M turns of enameled wire on the outer edge of the grid insulating material, where M is a positive integer;

[0044] Winding (H-1) layers of enameled wires based on the above method, a grid-shaped insulating material is arranged between adjacent layers of enameled wires, and H is a positive integer;

[0045] (A2) In the winding of the enameled wire with the Mth turn of the H layer, the enameled wire is wrapped with an insulating cloth, thereby forming the first part with the H layer and M turns of the enameled wire;

[0046] (A3) The enameled wire wrapped with insulati...

Embodiment 2

[0048] An application example of the winding method according to Embodiment 1 of the present invention in the manufacture of dry-type transformer coils.

[0049] In this application example, the winding method of the transformer coil includes the following steps:

[0050] (A1) Lay a grid-shaped insulating material distributed along the circumferential direction of the inner ring on the outer edge of the cylindrical inner ring, and wind M turns of enameled wire on the outer edge of the grid-shaped insulating material;

[0051] Winding (H-1) layers of enameled wires based on the above method, and a grid-shaped insulating material is arranged between adjacent layers of enameled wires;

[0052] (A2) In the winding of the enameled wire with the Mth turn of the H layer, the enameled wire is wrapped with an insulating cloth, thereby forming the first part with the H layer and M turns of the enameled wire;

[0053] (A3) The enameled wire wrapped with insulating cloth is wound on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com