Clamping device for transformer coil and work method of clamping device

A clamping device and inner ring technology, applied in the manufacture of inductors/transformers/magnets, coils, electrical components, etc., can solve problems such as difficulty in meeting requirements, low work efficiency, and poor forming effects, and achieve good forming effects and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

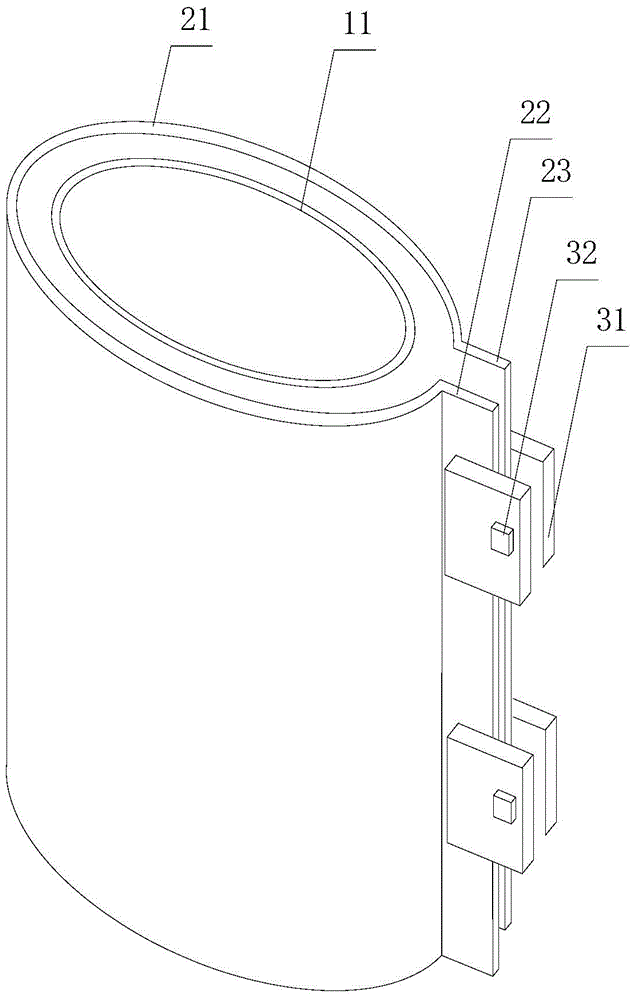

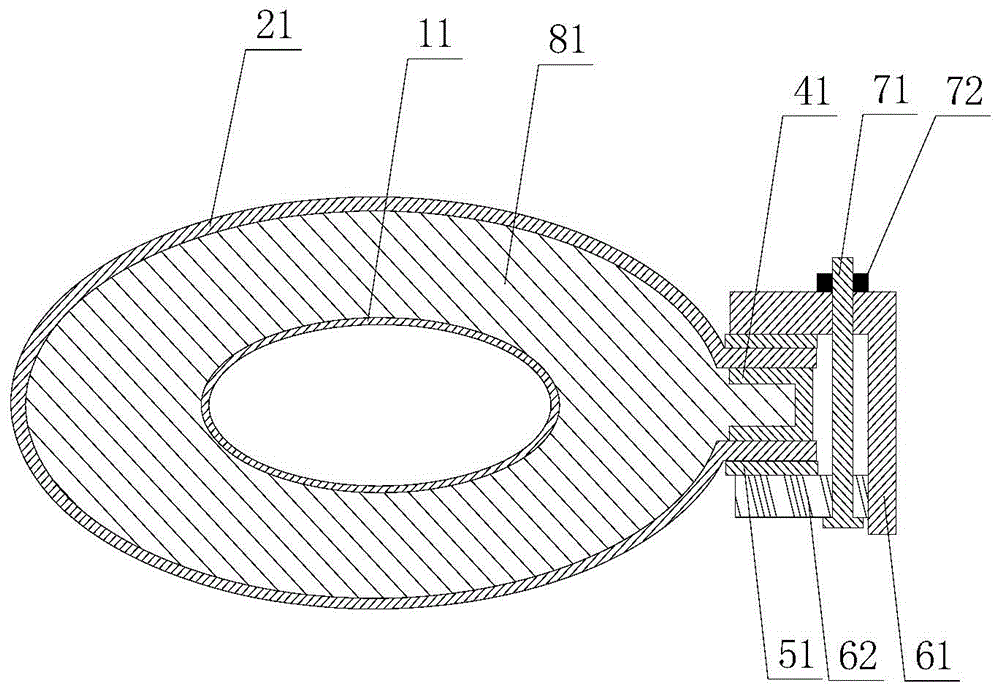

[0040] Figure 1-2 The basic structural diagram of the clamping device of the transformer coil in Embodiment 1 of the present invention is schematically given, as Figure 1-2 As shown, the clamping device includes:

[0041] A cylindrical inner ring 11 and a cylindrical outer ring 21. In the vertical direction, the inner ring and the outer ring are formed with arc surfaces and have openings. The openings include extensions 22 and 23 on both sides;

[0042] A support piece 81, the support piece is in the shape of a standard coil, and is installed horizontally between the inner ring and the outer ring;

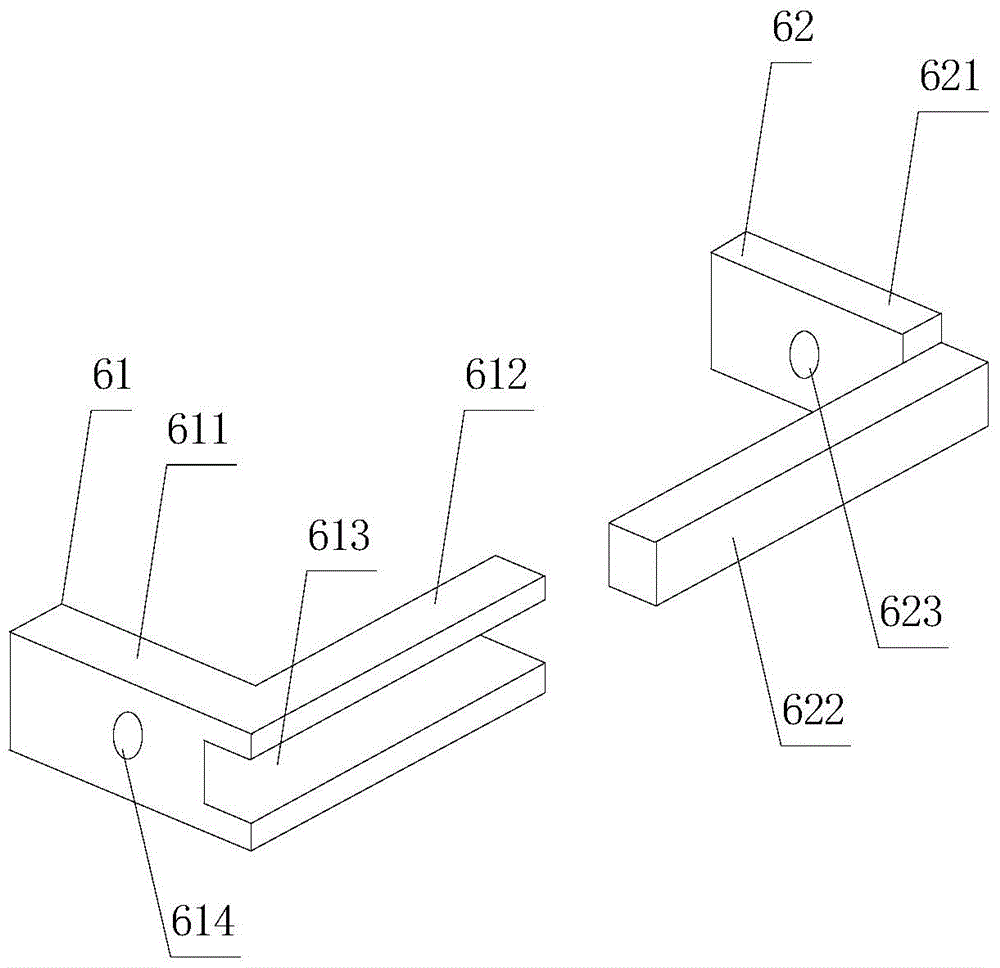

[0043] Spacer 41, the spacer is between the extensions forming the two sides of the opening; the horizontal section of the spacer is in the shape of “[”, and supports are provided in the horizontal direction inside to improve strength, such as welding metal strip.

[0044] The pressing block 51, which is a strip of metal, is arranged on the outside of the extensions 22, 23 whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com