Sludge forming all-in-one machine

A technology of sludge forming and integrated machine, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, mold extrusion granulation, etc. Problems such as the operation effect of the low-temperature belt dryer for sludge can achieve the effect of saving equipment investment cost, operation cost and maintenance cost, and less operation and maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

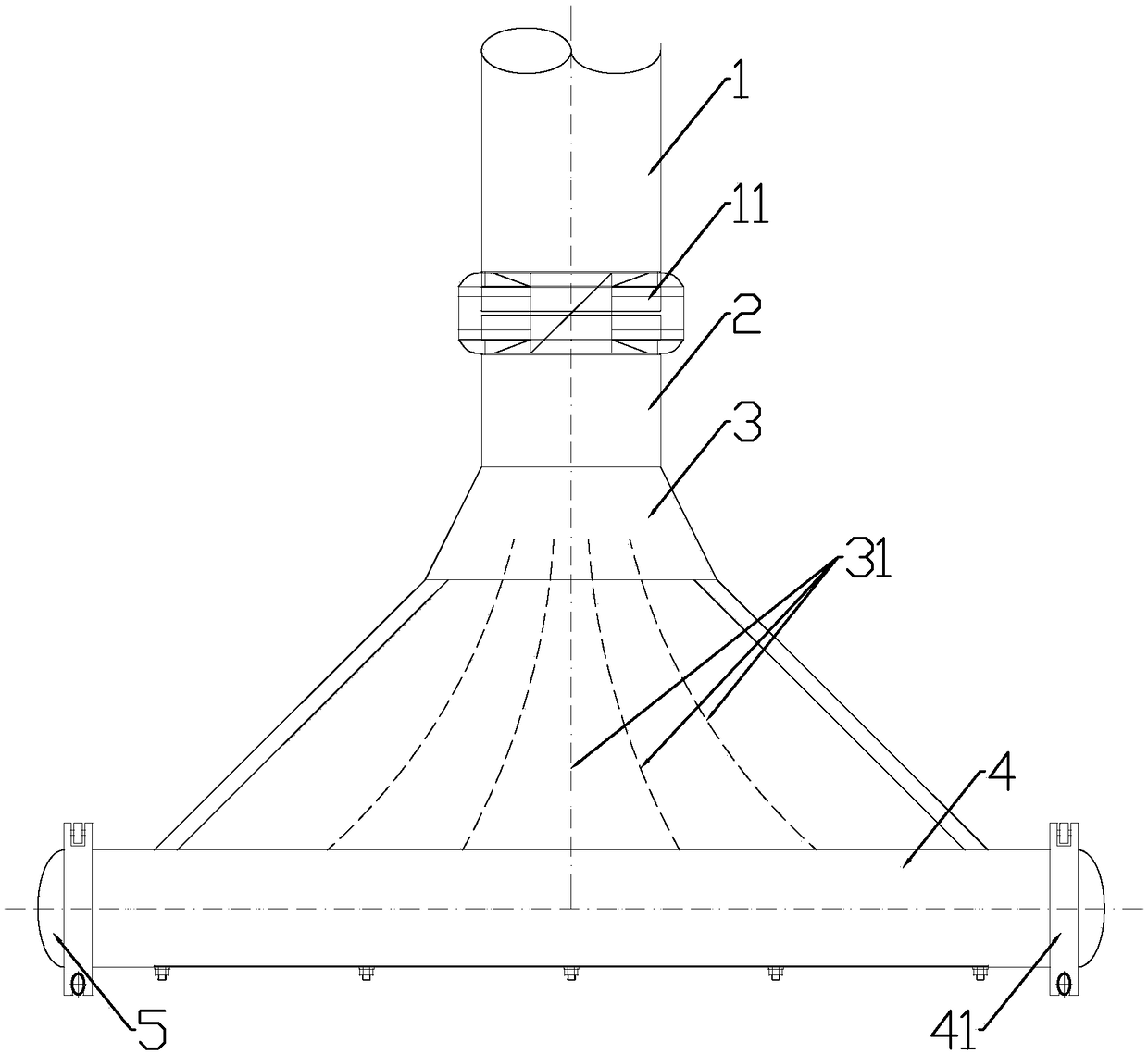

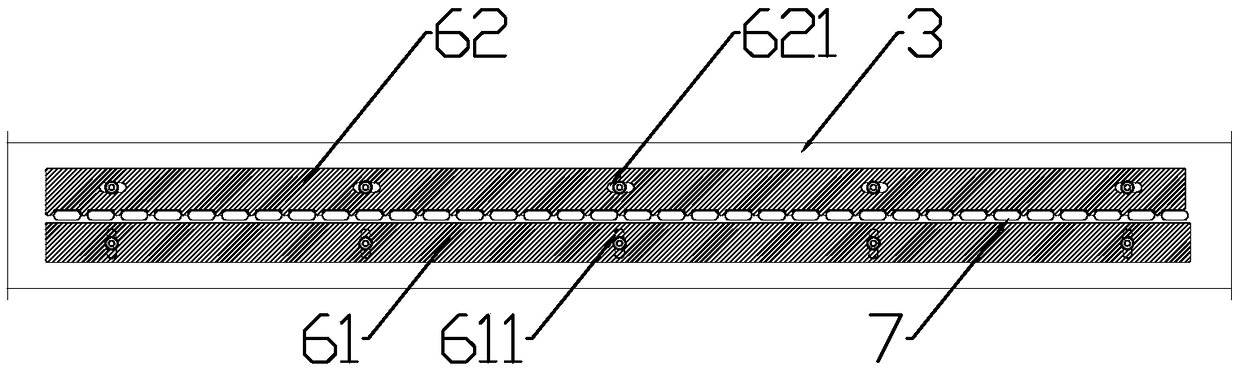

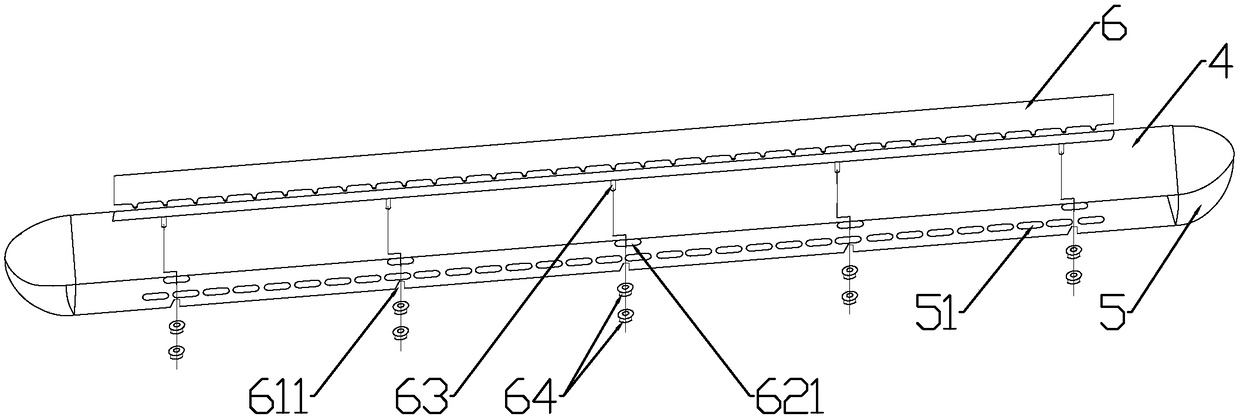

[0030] In this embodiment, the sludge forming machine is combined with figure 1 , the device includes a mud inlet pipe 2, a mud pipe 3, a forming pipe 4 and a mud cleaning pipe 5, combined with figure 2 , the mud inlet pipe 2 and the forming pipe 4 are connected with the mud pipe 3, and the mud outlet 7 is set at the bottom of the mud pipe 3, the mud pipe 3 is connected with the forming pipe 4 through the mud outlet 7, and the mud inlet pipe The bottom part of 2 and the mud separating pipe 3 form a mud separating area, and one end connected to the mud separating pipe 3 and the mud inlet pipe 2 is a special-shaped short pipe. The mud guide groove 31 is located in the mud separating area at the same time, and the distance between the mud guide groove 31 is calculated and designed according to the sludge flow rate to ensure that the sludge from the vertical circular pipe in the mud inlet area is reasonably and evenly distributed to the horizontal circular pipe in the forming are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com