Diene selection hydrogenation catalyst, and preparation method

A technology for selective hydrogenation and catalyst, which can be used in catalyst activation/preparation, hydrocarbon production by hydrogenation, catalyst support, etc., and can solve the problems of higher reaction conditions and the need for further improvement of diene hydrogenation activity, selectivity and stability. , to achieve the effect of simple preparation method, high selectivity and stability, and efficient selective hydrogenation of diene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

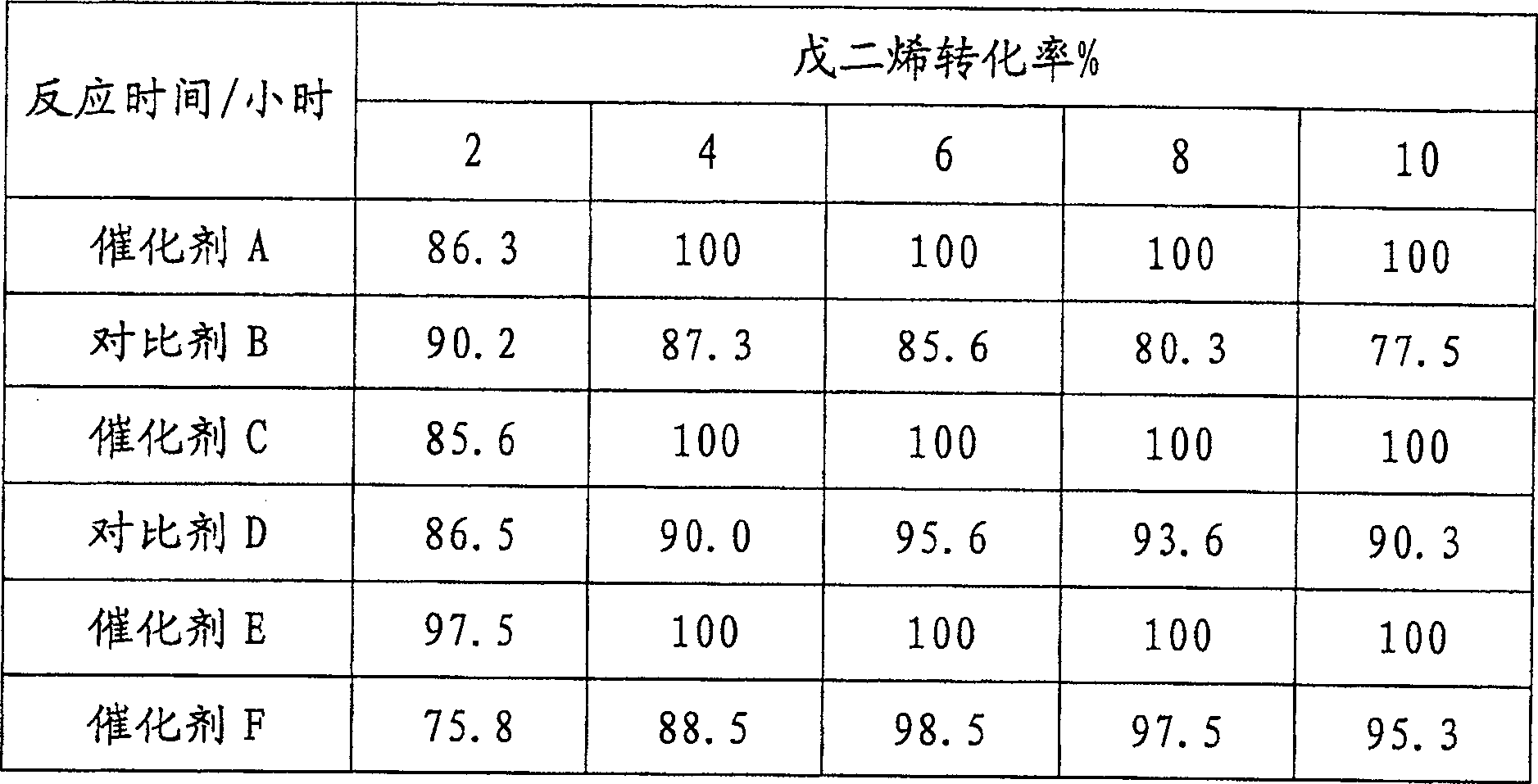

Embodiment 1

[0026] Put an appropriate amount of small balls with a diameter of φ1~2mm γ-Al 2 O 3 The carrier (Catalyst Plant of Fushun Petrochemical Company) was roasted in a muffle furnace at 1100°C for 4 hours. After cooling, it was used as a carrier for subsequent catalysts. 95%, the specific surface area is 101m 2 / g.

Embodiment 2

[0028] Weigh 165 grams of the alumina carrier prepared in Example 1, and use 119.3 grams of nickel nitrate Ni[(NO 3 ) 2 ·6H 2 O] and 115.5 ml of distilled water were immersed in an equal volume for 2 hours. After preliminary drying at room temperature, the catalyst A was prepared by vacuum drying at a constant temperature of 160°C for 7 hours to prepare a catalyst A with a metal Ni loading of 14.6%wt.

Embodiment 3

[0030] Put 130 grams of γ-Al balls with a diameter of φ1~2mm without high temperature treatment 2 O 3 The carrier (catalyst plant of Fushun Petrochemical Company) was prepared according to the method of Example 2 to prepare the catalyst contrast agent B with the same Ni metal content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com