High-loading-capacity nickel-aluminum catalyst as well as preparation method and application thereof

A catalyst and nickel-aluminum technology, which is applied in the field of high-load nickel-aluminum catalyst and its preparation, can solve the problems of Raney nickel storage and transportation safety hazards, environmental pollution, oxidative combustion, etc., and achieve safe storage and transportation improvement and optimization. Hydrogen process, the effect of reducing the cost of hydrogenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

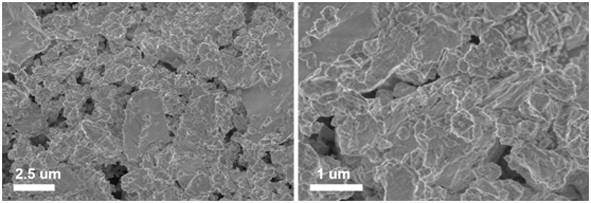

[0038] A preparation method of a high-load nickel-aluminum catalyst comprises:

[0039] Step S1: mixing a certain molar ratio of nickel salt solution, aluminum salt solution and magnesium salt solution uniformly, and stirring on a magnetic stirrer for 30 min, so that the metal ions are completely and uniformly dispersed;

[0040] Step S2: Synthesis of metal oxide precursor: adding a precipitant to the above metal solution, stirring at room temperature for 20 min, and then placing it in an oil bath to stir the reaction, and then centrifuging, washing with distilled water until neutral, and calcining to obtain the metal oxide precursors; and

[0041] Step S3: Reduction and Magnesium Evaporation Induction: The oxide precursor is placed in a tube furnace, and the reduction is performed first, and then the temperature is changed to the evaporation induction temperature to evaporate the Mg element to induce the production of stable nickel with a high load Aluminum catalyst.

[004...

Embodiment 2

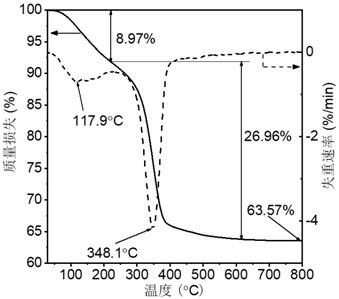

[0055] A high-load nickel-aluminum catalyst can be prepared by using the preparation method of the nickel-based catalyst provided in Example 1;

[0056] The molecular formula of the high-loaded nickel-based carbide catalyst is Ni x -Mg y / Al 2 O 3 -T, where x / y represents the molar ratio of nickel and magnesium charged, and T represents the temperature induced by the evaporation of Mg;

[0057] As a supported catalyst, the loading of the catalyst is 50wt%-90wt%;

[0058] Preferably, 0.5≤x / y≤4;

[0059] Preferably, 500≤T≤900.

[0060] In some specific embodiments, the molecular formula of the nickel-based catalyst is Ni 3 -Mg 3 / Al 2 O 3 -800.

Embodiment 3

[0062] An application of a high-capacity nickel-based carbide catalyst, the high-capacity nickel-aluminum catalyst provided in Example 2 is applied to the hydrogenation reaction of fused-ring aromatic hydrocarbons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com