Nanometer auxiliary biological hydrogenation thickened oil yield increasing method

A heavy oil and biological technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of narrowing of heavy oil circulation channels, reduction of effective permeability, and impact on oil production, etc., to improve heavy oil production. quality, increase the seepage capacity of the oil phase, and promote the effect of reducing the viscosity of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

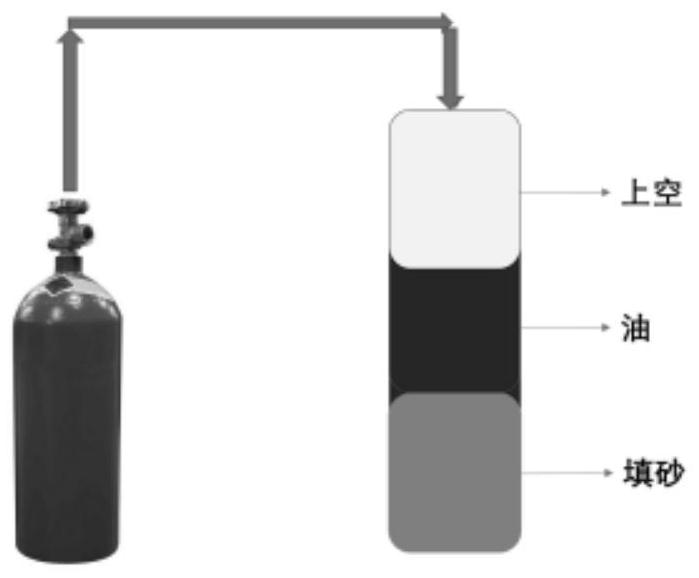

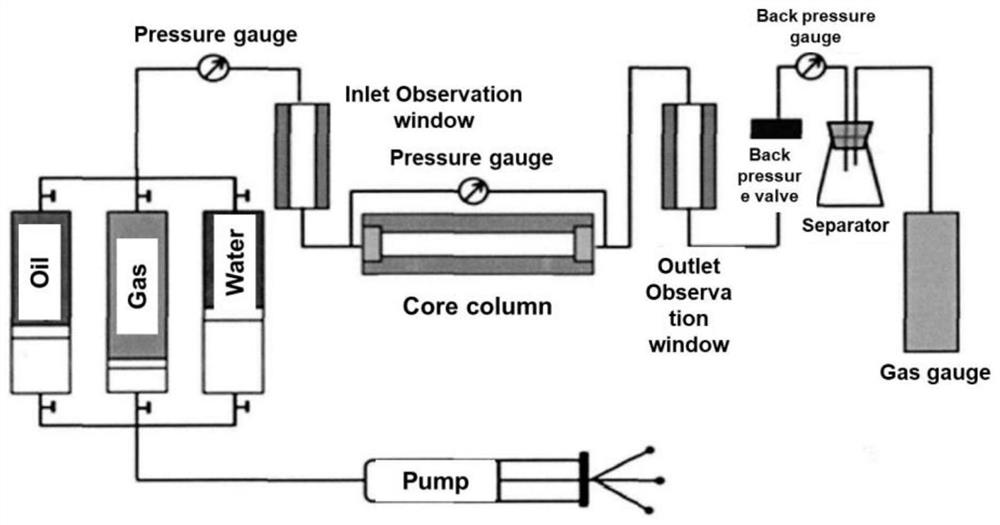

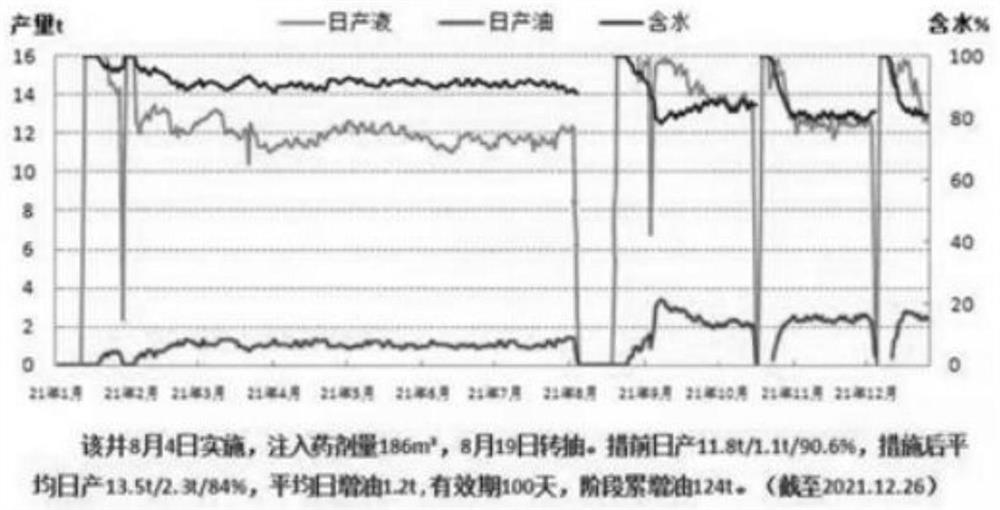

[0055] The nano-assisted biological hydrogenation heavy oil production increasing method of the present embodiment comprises the following steps:

[0056] (1) Analysis of reservoir geological characteristics, oil well production, reservoir minerals, formation water and heavy oil components, and heavy oil viscosity-temperature curve in a heavy oil block in Jilin Oilfield;

[0057] (2) According to the information in (1), according to the method of the present invention, the following combination is obtained by optimization: by mass percentage, microbial inoculum is 6%, hydrogen-producing nutrient solution is 10%, iron oxide is 0.05%, and the balance is water. Wherein the microbial inoculum is prepared by fermentation of Clostridium bacteria, and is mixed uniformly according to the above-mentioned preparation method to obtain the combined hydrogen-producing preparation A.

[0058] Wherein the microbial inoculum is prepared by fermentation of Clostridium inoculum, and the medium ...

Embodiment 2

[0068] The nano-assisted biological hydrogenation heavy oil production increasing method of the present embodiment comprises the following steps:

[0069] (1) Analysis of reservoir geological characteristics, oil well production, reservoir minerals, formation water and heavy oil components, and heavy oil viscosity-temperature curve in a heavy oil block in Liaohe Oilfield.

[0070] (2) According to the information in (1), according to the method of the present invention, the following combination is obtained by optimization: in terms of mass percentage, 10% of special microbial inoculants, 20% of hydrogen-producing nutrient solution, 0.03% of titanium dioxide, 0.001% of graphene, and the remainder The amount is water. Among them, the special microbial inoculum is prepared by fermentation of Citrobacter bacteria. According to the above-mentioned preparation method, the mixture is evenly mixed to obtain the combined hydrogen-producing preparation B.

[0071] The special microbia...

Embodiment 3

[0080] The nano-assisted biological hydrogenation heavy oil production increasing method of the present embodiment comprises the following steps:

[0081] (1) Analysis of reservoir geological characteristics, oil well production, reservoir minerals, formation water and heavy oil components, and heavy oil viscosity-temperature curve in a heavy oil block in Nanyang Oilfield.

[0082] (2) According to the information in (1), according to the method of the present invention, the following combinations are obtained by optimization: by mass percentage, 12% of special microbial inoculants, 15% of hydrogen-producing nutrient solution, 0.1% of zinc oxide, 0.02% of copper oxide, Manganese oxide 0.02%, the balance is water. The special microbial inoculant is prepared by fermentation of Thermoanaerobacterium bacteria and Bacillus bacteria (mass ratio is 1:1) respectively. According to the above preparation method, the mixture is uniformly mixed to obtain a combined hydrogen-producing prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com