Production method and device of removing internal stress of steel wire for cold upsetting

A steel wire rod and production method technology, applied in the direction of manufacturing tools, improvement of process efficiency, furnace type, etc., can solve problems such as easy carbonization or sintering of steel wire rod, unfavorable cold heading forging, complicated equipment, etc., and achieve good processing Performance, ease of use, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

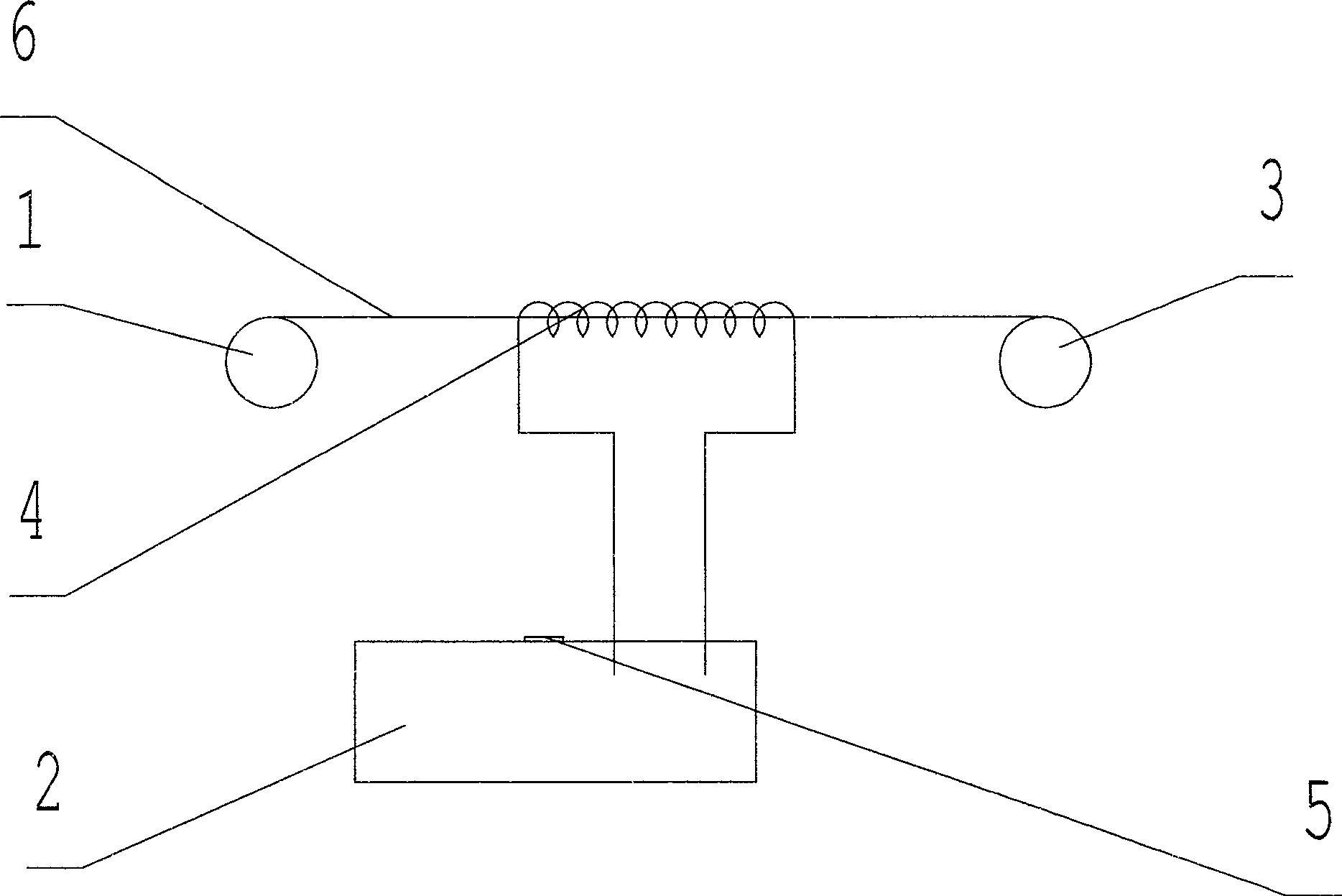

[0021] Such as figure 1 As shown, the device for eliminating the internal stress of the steel wire used for cold heading and forging includes a pay-off stand 1, a high-frequency electric induction heater 2, and a take-up stand 3. The high-frequency electric induction heater is provided with a ring coil 4. The high-frequency electric induction heater 2 is provided with an infrared thermometer 5 .

[0022] Production method and steps of the present invention are as follows:

[0023] A. The starting end of the steel wire rod 6 used for cold heading forging passes through the ring coil 4 of the high-frequency electric induction heater 2 and is fixed on the wire rod take-up frame;

[0024] B. The high-frequency electric induction heater 2 is energized to heat the steel wire rod 6 for cold heading and forging;

[0025] C. The steel wire rod 6 for cold heading is heated to 200° C. to 700° C. in the toroidal coil 4 .

[0026] D. The steel wire rod 6 used for cold heading and forgin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com