Production of lignin modified water polyurethane

A water-based polyurethane and lignin technology, which is applied in the direction of lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems of complex preparation process and decline of modification technology, and achieve low production cost, abundant sources, stretchable high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method for lignin modified waterborne polyurethane, it comprises the steps:

[0020] 1). Mix the calculated amount of polyoxypropylene diol (molecular weight 2000, Nanjing Zhongshan Petrochemical) and toluene diisocyanate (TDI, China Pharmaceutical Group Shanghai Chemical Reagent Company) and stir at 65°C for 2 hours to obtain water-based polyurethane prepolymerization The mass percent of polyoxypropylene diol and toluene diisocyanate is: polyoxypropylene diol 10, toluene diisocyanate 90;

[0021] 2). Add a small molecule chain extender to the water-based polyurethane prepolymer obtained in step 1) at 75°C: 2,2'-dimethylol propionic acid (DMPA, Huzhou Changsheng), small molecule chain extender The amount of DMPA added is 10% of the mass of toluene diisocyanate [so that the NCO / OH molar ratio of the obtained lignosulfonate composite water-based polyurethane emulsion is 1.0-3.5, [-OH] in the small molecule chain extender and polyoxygen In propylene glycol, ...

Embodiment 2

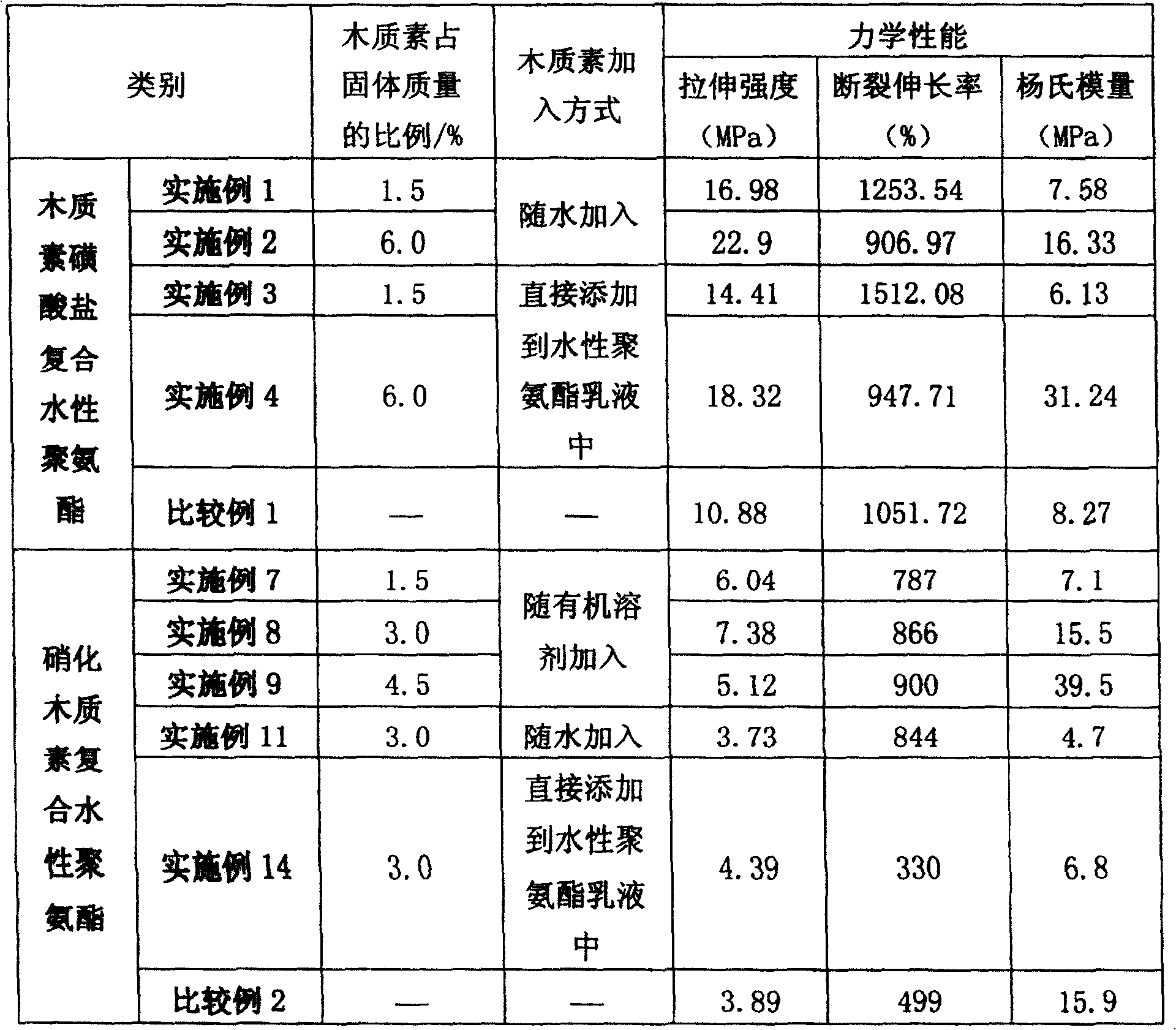

[0028] It is basically the same as Example 1, except that the lignosulfonate added is 6.0% of the solid mass of polyoxypropylene diol, toluene diisocyanate and 2,2'-dimethylol propionic acid to obtain lignin Modified water-based polyurethane (or lignosulfonate composite water-based polyurethane emulsion). The mechanical properties of the material obtained after the same test: the tensile strength is 22.9MPa, and the elongation at break is 906.97%. Compared with the blank material, the tensile strength is increased by 2.1 times, but the elongation at break is reduced to the original 86%.

Embodiment 3

[0030] A kind of preparation method of lignin modified waterborne polyurethane, it comprises the steps:

[0031] 1). Mix the calculated amount of polyoxypropylene diol (molecular weight 2000) with toluene diisocyanate (TDI) and stir at 65°C for 2 hours to obtain a water-based polyurethane prepolymer; the mass of polyoxypropylene diol and toluene diisocyanate The percentage is: polyoxypropylene diol 35, toluene diisocyanate 65;

[0032] 2). Add small molecule chain extender to the aqueous polyurethane prepolymer obtained in step 1) at 75°C: 2,2'-dimethylol propionic acid (DMPA, Huzhou Changsheng), small molecule chain extender DMPA The addition amount is 50% of the toluene diisocyanate quality (making the NCO / OH molar ratio in the obtained lignosulfonate composite aqueous polyurethane emulsion be 1.0-3.5, [-OH] and polyoxypropylene diisocyanate in the small molecule chain extender [-OH] molar ratio in the alcohol is within the scope of 1.0-3.5), stirred and reacted for 1 hour,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com