Asymmetric polymerase chain reaction technology based on nano particles

A nanoparticle and magnetic nanoparticle technology, applied in the field of asymmetric polymerase chain reaction technology, can solve the problems of lack of preparation and separation of single-stranded DNA, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In a preferred example, the preparation method of the PCR primer based on nanoparticles of the present invention comprises the following steps:

[0054] (1) Preparation of magnetic nanoparticles

[0055] Double distilled H2O 2 O separately prepared FeSO 4 ·7H 2 O and FeCl 3 ·6H 2 O mixed solution and NaOH solution. In a mixed solution of iron salts, Fe 2+ The ion concentration is 0.1~0.2mol / l, Fe 3+ The concentration of ions is 0.1-0.3 mol / l, and the concentration of NaOH solution is 2-3 mol / l. Under vigorous stirring, the NaOH solution whose volume is half of the volume of the mixed salt solution was slowly added dropwise into the mixed salt solution. Aging the obtained solid precipitate at 40°C to 60°C for 12 hours, washing the precipitate several times with twice distilled water, filtering and drying at 40°C to 80°C for 24 hours, grinding it in an agate mortar That is the product.

[0056] (2) Silica in γ-Fe 2 o 3 surface modification

[0057] Mix Triton...

Embodiment 1

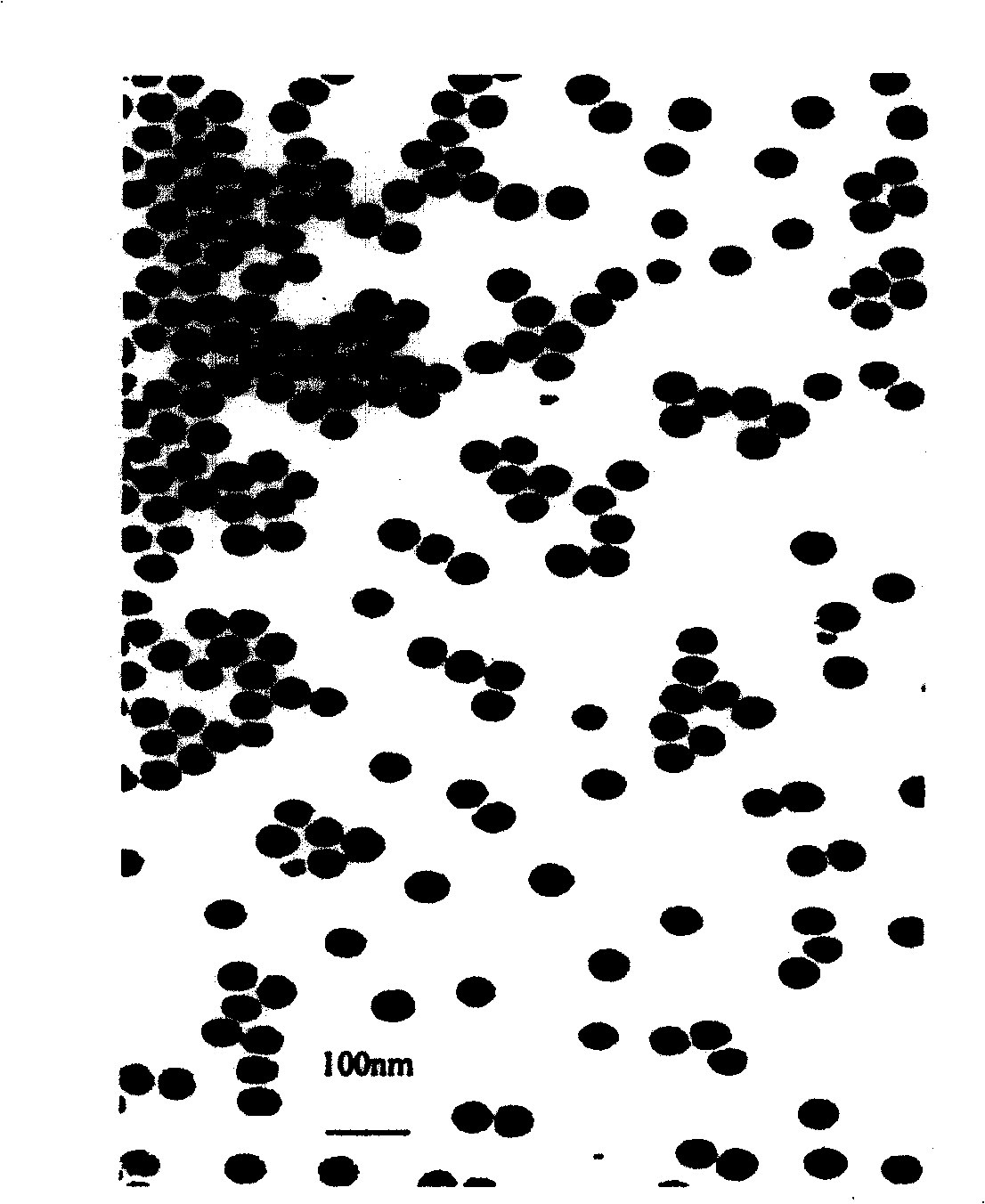

[0077] Preparation method of inner core layer of magnetic nanoparticles

[0078] The core layer of magnetic particles was prepared by improved chemical co-precipitation, the specific method is as follows: prepare FeSO 4 ·7H 2 O and FeCl 3 ·6H 2 O mixed solution and NaOH solution. In a mixed solution of iron salts, Fe 2+ The ion concentration is 0.1~0.2mol / l, Fe 3+ The concentration of ions is 0.1-0.3 mol / l, and the concentration of NaOH solution is 2-3 mol / l. Under vigorous stirring, the NaOH solution whose volume is half of the volume of the mixed salt solution was slowly added dropwise into the mixed salt solution. Aging the obtained solid precipitate at 40°C to 60°C for 12 hours, washing the precipitate several times with double distilled water, filtering and drying at 40°C to 80°C for 24 hours, and grinding it in an agate mortar Get the product.

Embodiment 2

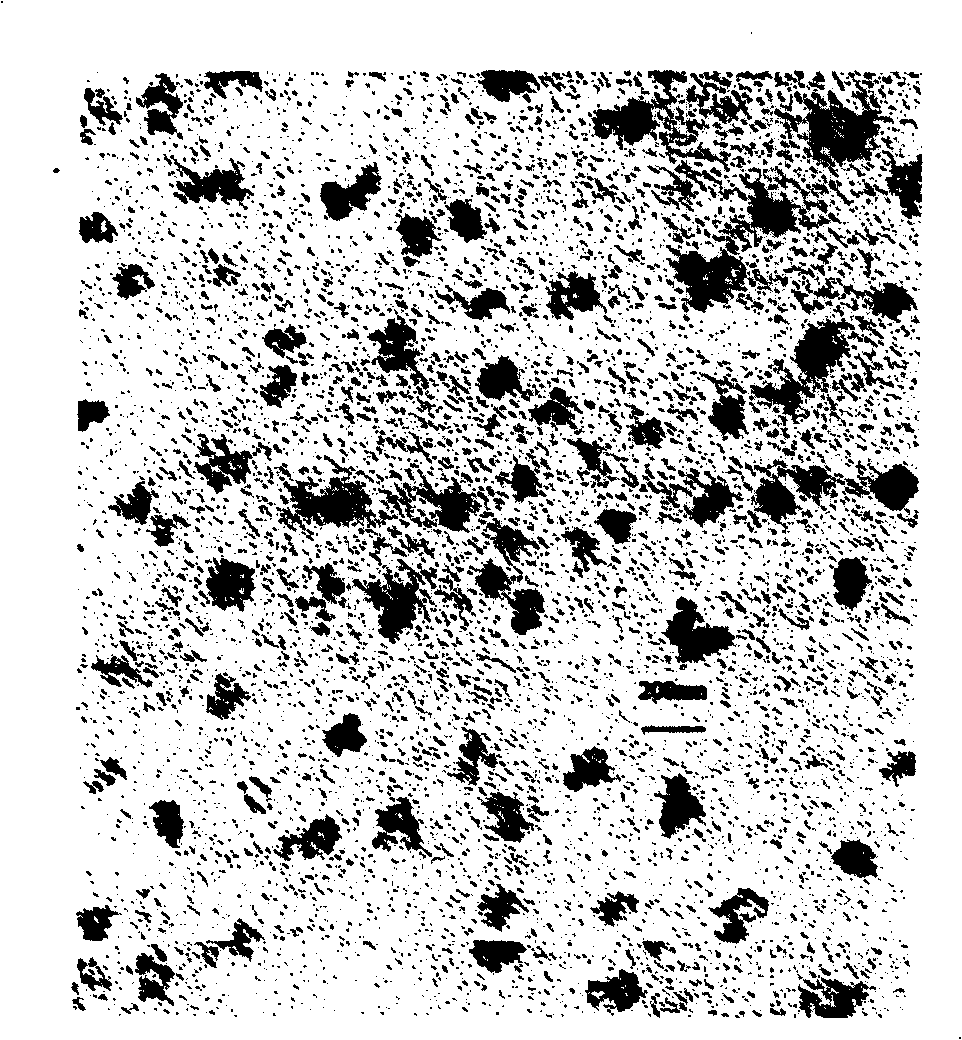

[0080] Preparation method of core-shell nucleic acid magnetic nanoparticles

[0081] Mix TritonX-100, n-hexanol and cyclohexane uniformly at a ratio of 1:2:5 to form a transparent and stable microemulsion system. Put the microemulsion system above into ultrasonic treatment for 30-60 minutes, then add 0.5g of γ-Fe 2 o 3After 6 minutes of ultrasonic treatment, the supernatant was taken out and poured into a three-necked flask, and stirred for 30 minutes to make it uniform. Take 1ml of a certain concentration of concentrated ammonia water and dilute it with 2ml of double distilled water, slowly add it into the microemulsion that is constantly stirring after 30 minutes, and keep stirring for 30 minutes to make the ammonia water evenly dispersed in the microemulsion. After 1 hour, 1-3 ml of tetraethyl orthosilicate was added dropwise to the microemulsion, while stirring continuously for 10 hours, and the temperature of the system was kept between 15-30°C. Add acetone to the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com