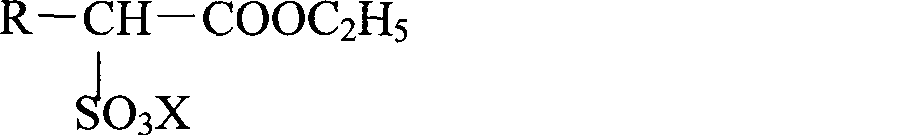

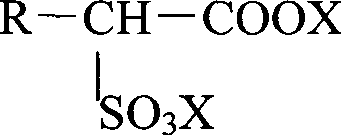

Mixture containing fatty acid ethyl sulfonate and preparation method thereof

A technology of fatty acid ethyl ester sulfonate and fatty acid ethyl ester sulfonic acid, which is applied in chemical instruments and methods, chemical/physical processes, dissolution and other directions, and can solve problems such as undiscovered, protein fiber damage, and carcinogenicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (embodiment 1) preparation creamy mixture containing fatty acid ethyl ester sulfonate

[0023] ① Take fatty acids with a carbon chain length of 12-18 for ethylation reaction to obtain fatty acid ethyl esters, heat the fatty acid ethyl esters to 45°C, and then pressurize the heated fatty acid ethyl esters to 20kg / cm through a high-pressure pump 2 , and then sent into the high-pressure jet atomizer to atomize the fatty acid ethyl ester; carry out the sulfonation reaction with the atomized fatty acid ethyl ester and gaseous sulfur trioxide in a molar ratio of 1: 1.1, and the time of the sulfonation reaction is 15s, the temperature is 85°C, and the pressure is 0.05Mpa. The products are fatty acid ethyl ester sulfonic acid and sulfo fatty acid. Fatty acid ethyl ester is contacted and mixed with gaseous sulfur trioxide, wherein the foggy fatty acid ethyl ester flows in a straight line, while the gaseous sulfur trioxide flows in a vortex.

[0024] ② Add ethanol to the mixed ...

Embodiment 2

[0029] (embodiment 2) preparation creamy mixture containing fatty acid ethyl ester sulfonate

[0030] ① Take fatty acid with a carbon chain length of 12-18 for ethylation reaction to obtain fatty acid ethyl ester, heat the fatty acid ethyl ester to 50°C, and then pressurize the heated fatty acid ethyl ester to 30kg / cm through a high-pressure pump 2, and then sent into the high-pressure jet atomizer to atomize the fatty acid ethyl ester; carry out the sulfonation reaction with the atomized fatty acid ethyl ester and gas phase sulfur trioxide in a molar ratio of 1: 1.05, and the time of the sulfonation reaction is 25s, the temperature is 80°C, and the pressure is 0.01Mpa. The products are fatty acid ethyl ester sulfonic acid and sulfo fatty acid. Fatty acid ethyl ester is contacted and mixed with gaseous sulfur trioxide, wherein the foggy fatty acid ethyl ester flows in a straight line, while the gaseous sulfur trioxide flows in a vortex.

[0031] ② Add ethanol to the mixed ma...

Embodiment 3

[0036] (embodiment 3) preparation creamy mixture containing fatty acid ethyl ester sulfonate

[0037] ① Take fatty acid with a carbon chain length of 12-18 for ethylation reaction to obtain fatty acid ethyl ester, heat the fatty acid ethyl ester to 40°C, and then pressurize the heated fatty acid ethyl ester to 10kg / cm through a high-pressure pump 2 , and then sent into the high-pressure jet atomizer to atomize the fatty acid ethyl ester; carry out the sulfonation reaction with the atomized fatty acid ethyl ester and gaseous sulfur trioxide in a molar ratio of 1:1, and the time of the sulfonation reaction is 5s, the temperature is 90°C, and the pressure is 0.09Mpa. The products are fatty acid ethyl ester sulfonic acid and sulfo fatty acid. Fatty acid ethyl ester is contacted and mixed with gaseous sulfur trioxide, wherein the foggy fatty acid ethyl ester flows in a straight line, while the gaseous sulfur trioxide flows in a vortex.

[0038] ② Add ethanol to the mixed material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com