Process of heating lead-containing free-cutting steel

A technology of free-cutting steel and heating process, applied in the field of metallurgy, can solve the problems of insufficient utilization of heating capacity in the heating process, uneven temperature of the billet, blooming of the billet head, etc., and reduce the probability of slippage of the rolling groove and the probability of head splitting. , The effect of reducing equipment loss and improving rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

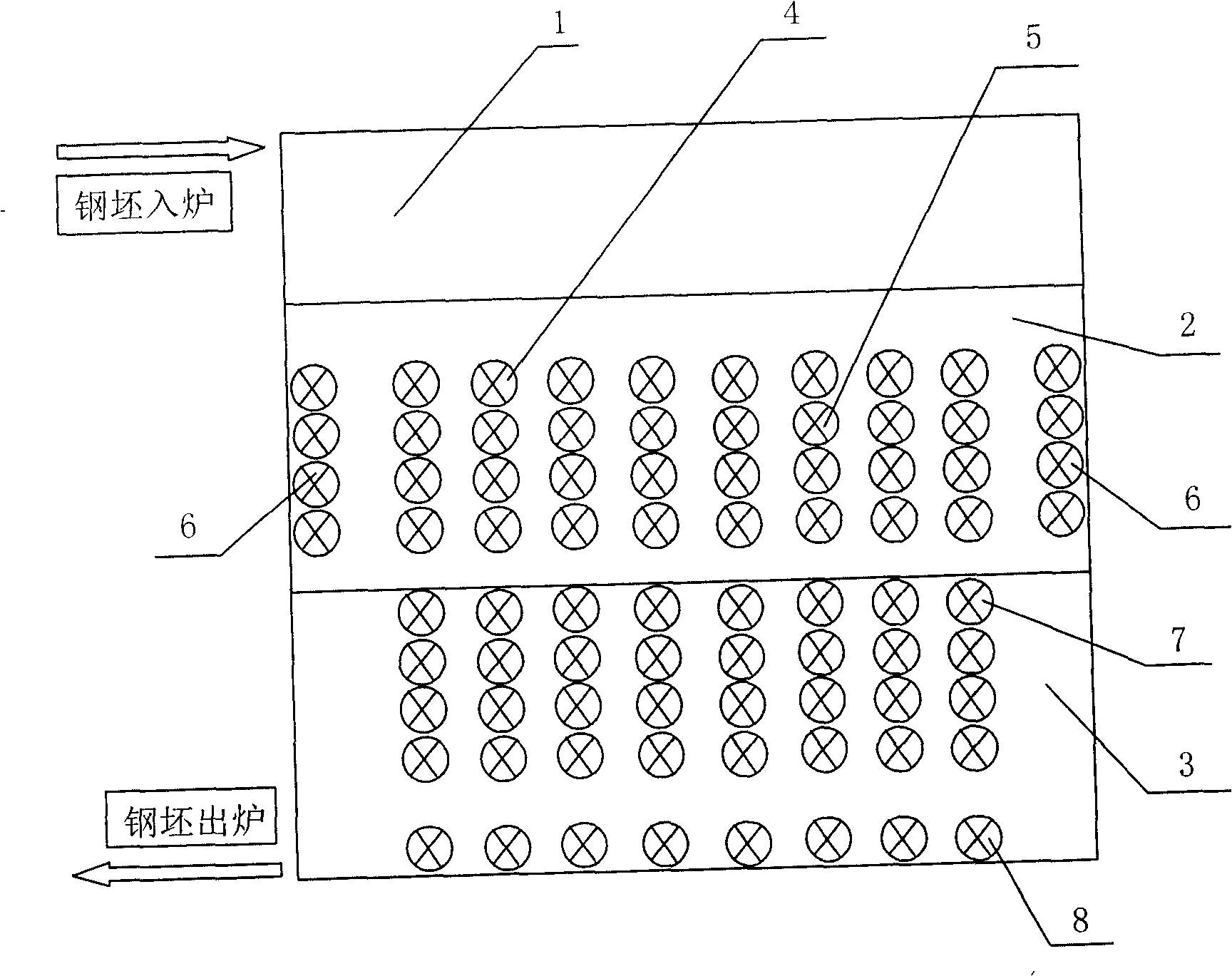

Image

Examples

Embodiment 1

[0030] This embodiment is a heating process of Φ5.5 lead-containing free-cutting steel, including a preheating process, a heating process, and a soaking process. The heating furnace is used for heating, the rolling speed is 94m / s, and the heating capacity is 60t / h. In the preheating process, the billet is preheated to 700°C by the waste heat of the heating section and the soaking section of the heating furnace, and the exhaust heat of the heating section and the soaking section is mainly used to draw the waste heat from the heating section and the soaking section to the end of the furnace, and the heating section The gas that is not completely burned in the soaking section continues to burn to ensure the temperature of the preheating section.

[0031] After the preheating process is completed, the lead-containing free-cutting steel billet is transported by the walking beam and enters the heating process from the preheating process. In the heating process, the billet is heated to 1...

Embodiment 2

[0039] This embodiment is a heating process for Φ6 lead-containing free-cutting steel, including a preheating process, a heating process, and a soaking process. The heating furnace is used for heating, the rolling speed is 86m / s, and the heating capacity is 64t / h. In the preheating process, the billet is preheated to 740°C by the waste heat of the heating section and soaking section of the heating furnace. The temperature of the preheating section is mainly used to draw the waste heat of the heating section and the soaking section to the end of the furnace by the exhaust of the flue gas tube, and the incompletely burned coal gas in the heating section and the soaking section continues to burn to ensure the temperature of the preheating section.

[0040] After the preheating process is completed, the lead-containing free-cutting steel billet is transported by the walking beam, and enters the heating process from the preheating process. In the heating process, the billet is heated t...

Embodiment 3

[0048] This embodiment is a heating process for Φ9 lead-containing free-cutting steel, including a preheating process, a heating process, and a soaking process. The heating furnace is used for heating, the rolling speed is 52m / s, and the heating capacity is 86t / h. In the preheating process, the billet is preheated to 780°C by the waste heat of the heating section and soaking section of the heating furnace. The temperature of the preheating section is mainly due to the exhausting force of the exhaust chimney of the furnace to draw the waste heat of the heating section and the soaking section to the end of the furnace, and the incomplete combustion of the gas in the heating section and the soaking section continues to burn, which can ensure the temperature of the preheating section.

[0049] After the preheating process is completed, the lead-containing free-cutting steel billet is transported by the walking beam, and enters the heating process from the preheating process. In the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com