Steam water-level high precision, high reliability electrode sensor

A steam drum water level, electrode type technology, applied in high pressure, steam drum water level electrode sensor, subcritical boiler drum water level sampling sensing measurement, ultra-high pressure field, can solve the complex structure of the steam cage heater and affect the sampling dynamics Problems such as response speed and increased difficulty in the manufacture of the whole machine can achieve the effects of shortening the temperature equilibrium time, good mechanical self-sealing performance of the electrode, and reducing the leakage rate of the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

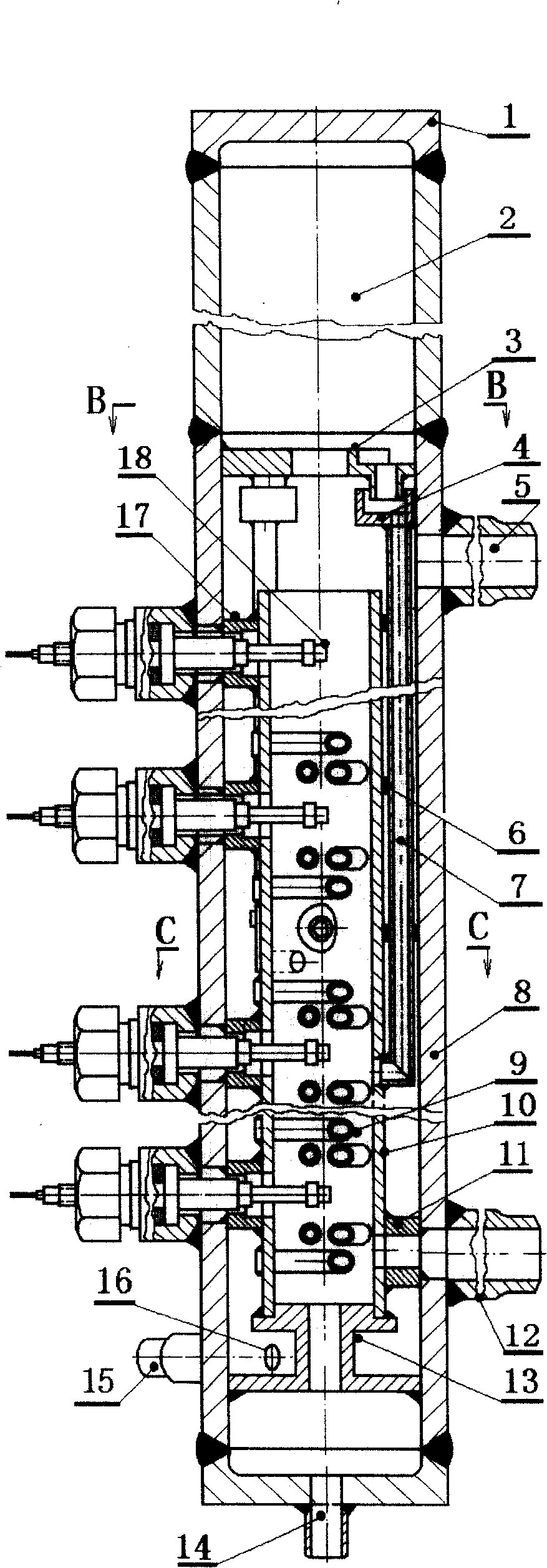

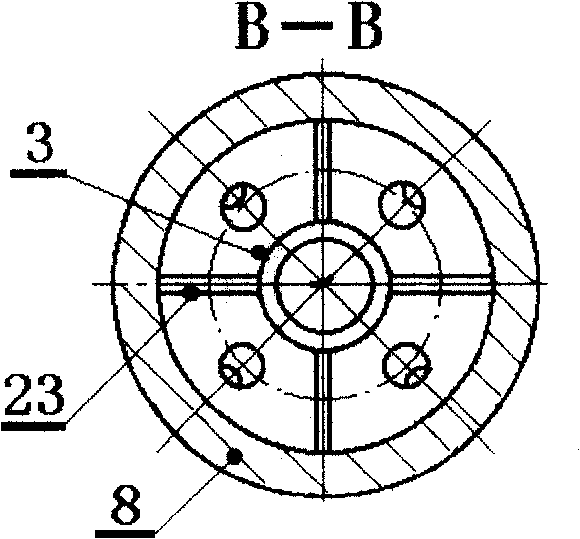

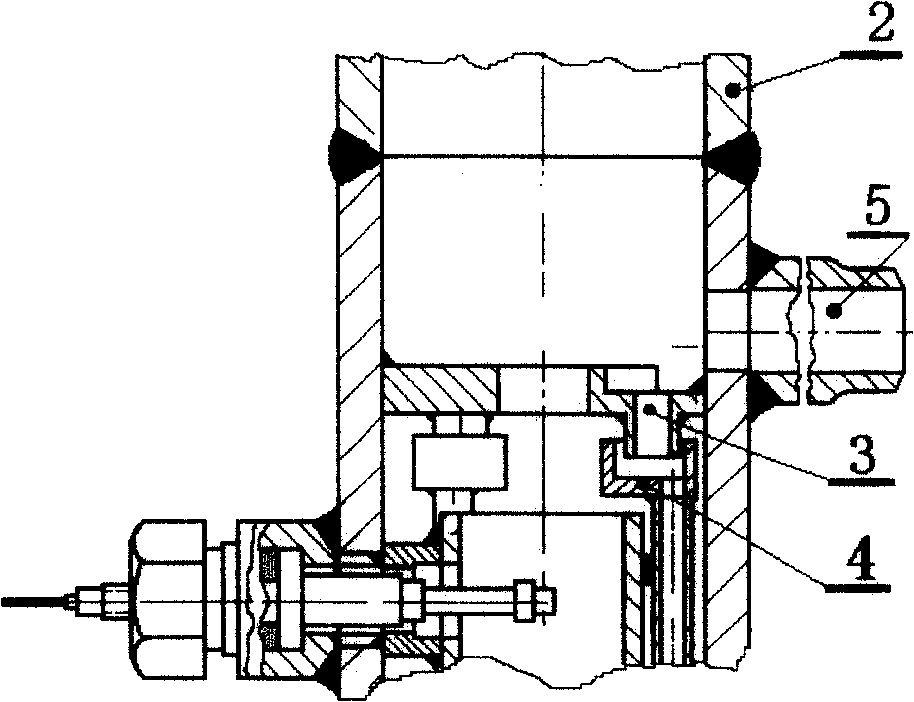

[0023] As shown in Figure 1, the present invention consists of steam cage heater, steam side sampling pipe 5, water side sampling pipe 12, electrode assembly, condensation chamber 2, water collection, water trapping device, cylinder body 8, heating drain pipe 15, blowdown pipe 14 compositions. The steam cage heater is a water column built-in type, mainly composed of a cylinder body 8, an inner cylinder 10, a horizontal heating pipe 9, an electrode passage pipe 17, a water intake passage pipe 11, a cage bottom 13, and a heating drain pipe 15. The steam cage heater is provided with a coaxial inner cylinder 10 in the cylinder, and a plurality of horizontal heating tubes 9 distributed along different radial directions of the inner cylinder are arranged in layers on different heights of the inner cylinder. It communicates with the annular cavity between the cylinder body 8 and the inner cylinder 10, and the upper part of the inner cylinder is open. The water column built-in steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com