Highly effective reaction deep-cone settling method and apparatus

A deep cone and reaction technology, which is applied in the direction of settling tanks, separation methods, chemical instruments and methods, etc., can solve the problems of high operating costs, low concentration of underflow discharge, difficult operation, etc., and achieve low investment and operating costs. The effect of low content, convenient operation, management and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

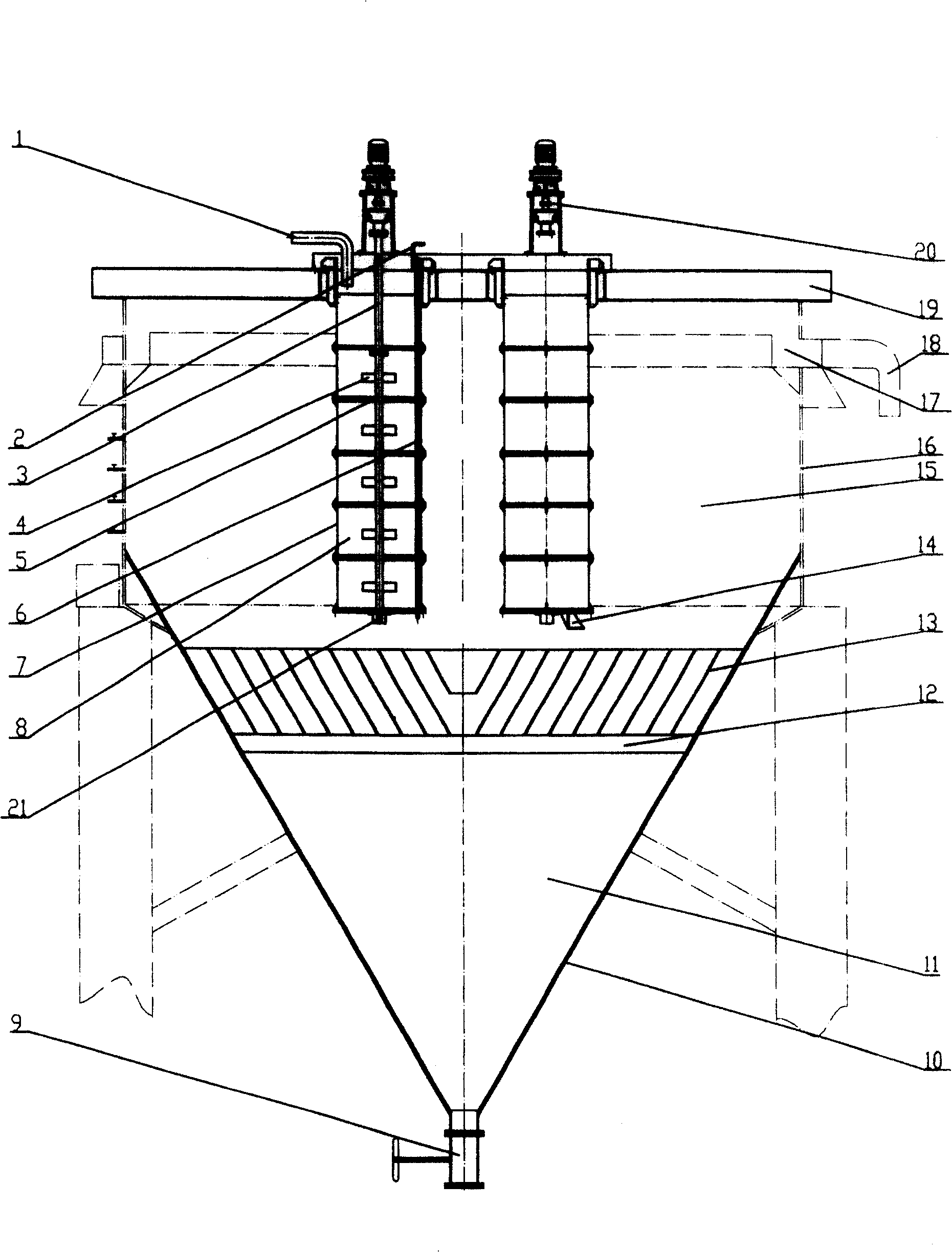

[0032] Mix 100 liters of coagulant such as polyacrylamide with a concentration of 25mg / L and 20M sewage with a particle concentration of 1 gram / liter 3 Enter the coagulation reaction chamber 8 of the cylinder 7 in the shell 16 of the coagulation reaction device through the dosing pipe 2 and the sewage inlet pipe 1 respectively, start the motor and its reducer 20, drive the stirring shaft 3 and the blade 4 to rotate, and adjust the speed 400 rev / min, so that the coagulant fully contacts with the suspended particles in the sewage to form floc suspended matter; the sewage containing this floc suspended matter is generated by the secondary flow generator 14 at the lower end of the coagulation reaction chamber 8 The secondary flow makes the floc suspension form large particle aggregates on the conical inclined plate 13 and slides down through the center of the conical inclined plate 13 to the deep cone concentration chamber 11, and the supernatant containing fine particles enters th...

example 2

[0034] Mix 500 liters of polyacrylamide with a concentration of 25 mg / L and 200 M of sewage with a concentration of 30 g / L 3 Enter the coagulation reaction chamber 8 of the cylinder 7 through the dosing pipe 2 and the sewage inlet pipe 1 respectively.

example 3

[0036] Mix 2000 liters of polyacrylamide with a concentration of 25mg / L and 400M sewage with a particle concentration of 60g / L 3 Enter the coagulation reaction chamber 8 of the cylinder 7 through the dosing pipe 2 and the sewage inlet pipe 1 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com