Overvoltage protector consitituted by multi-spark angle

A protection device and spark angle technology, applied in the direction of emergency protection circuit devices, emergency protection circuit devices, circuit devices, etc. for limiting overcurrent/overvoltage, can solve the problem of low research level of overvoltage protection devices and the ability to pass current Limitation and other issues, to achieve the effect of large export of transient pulse current and transient overvoltage, and expansion of current capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

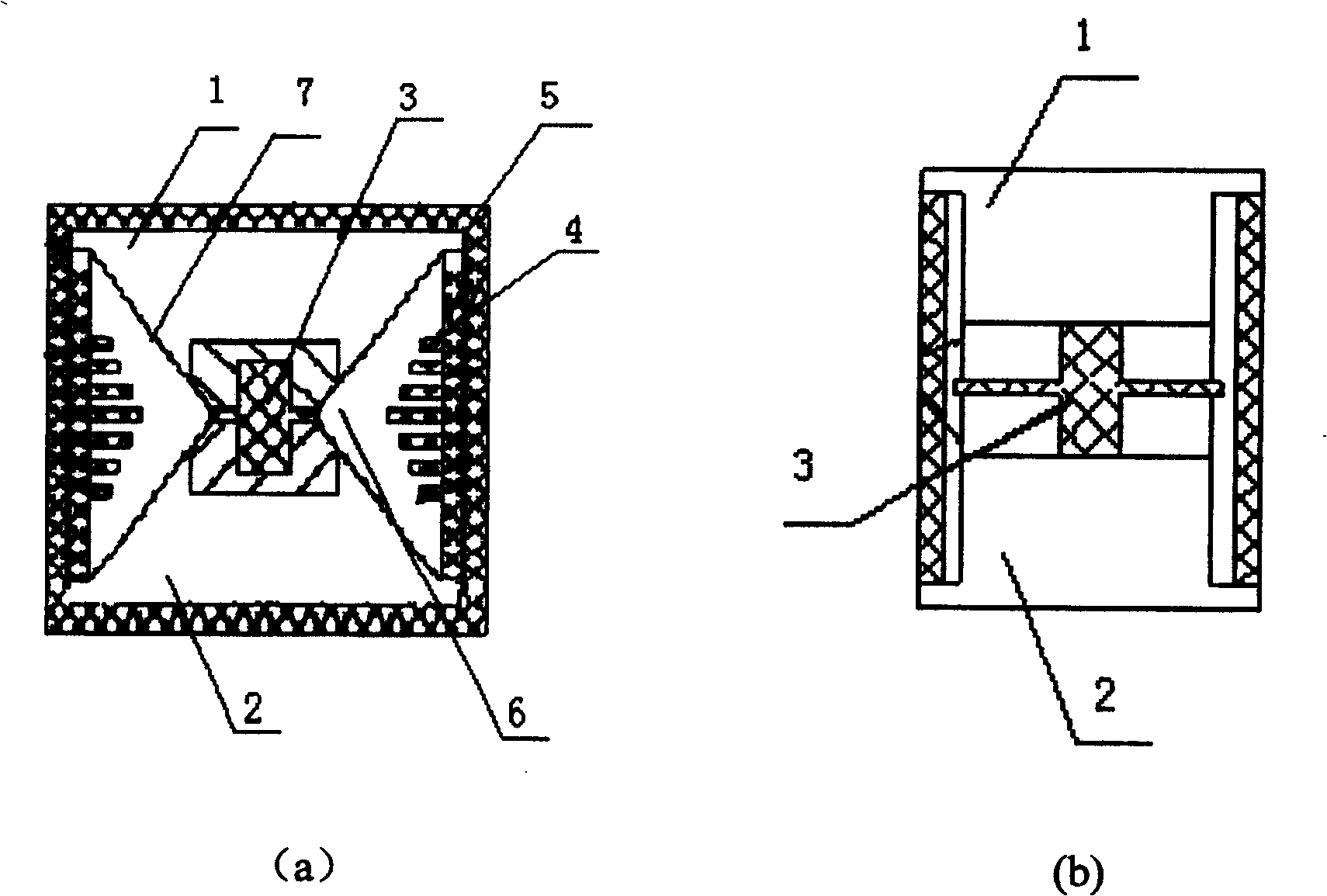

[0014] Embodiment 1: see figure 1 , the present invention comprises the electrode 1 and the electrode 2 of the frustum structure arranged in the insulating airtight casing 5 that is made of alumina ceramics, the edge of the electrode 1 and the electrode 2 of the frustum structure is set as a chamfered structure, the electrode 1 and the electrode 2 constitutes a pair of symmetrical V-shaped spark gaps 6, and an auxiliary ignition device 3 made of insulating material is also provided between the electrodes 1 and 2. The thickness of the auxiliary ignition device 3 is less than 1 mm, and the V-shaped symmetrical spark The surface of the gap 6 is the same size as the electrodes 1 and 2, and the plane perpendicular to the spark gap 6 is larger than the plane of the electrodes 1 and 2. Between the V-shaped spark gaps 6, there are also V-shaped spark gaps 6, respectively. The arc chute 4 is made of corresponding convex and concave metal or ceramic material.

[0015] In this embodimen...

Embodiment 2

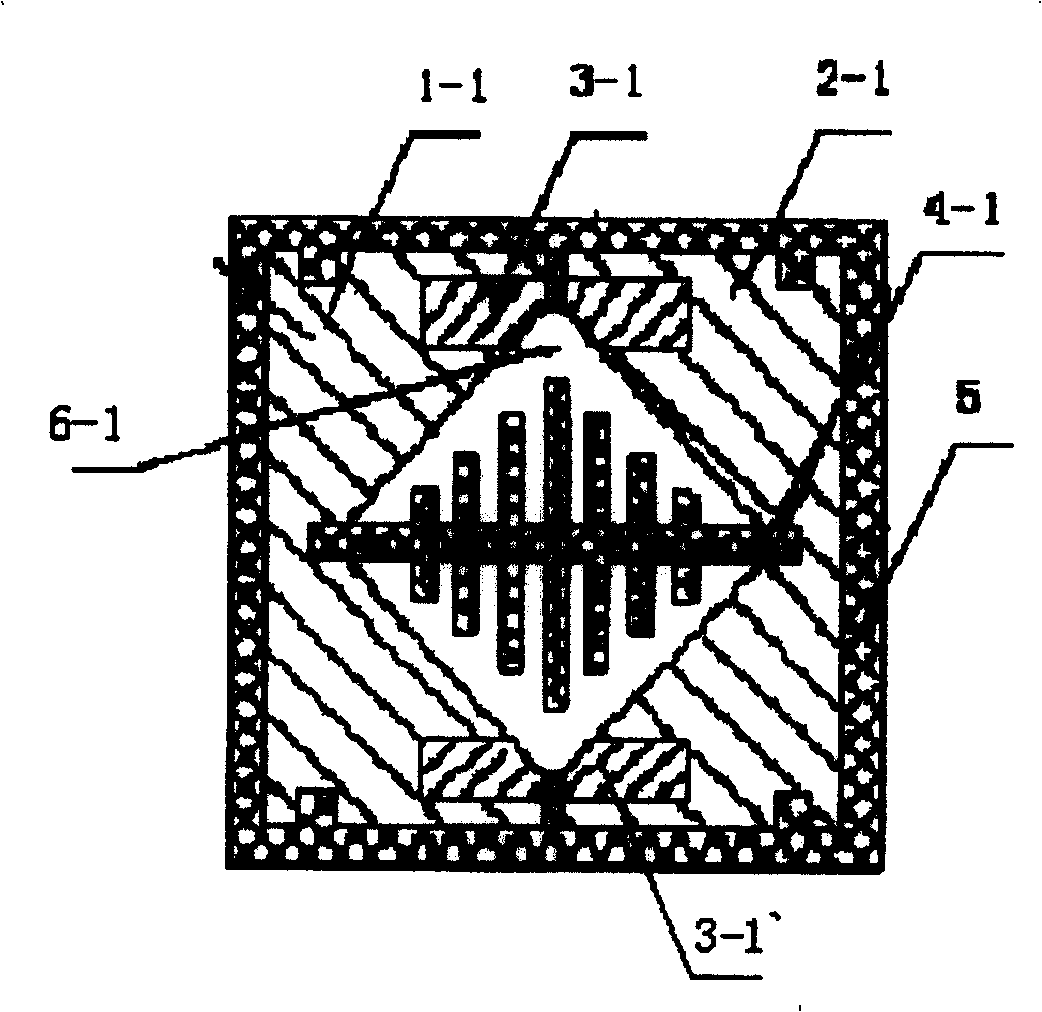

[0016] Example 2: see figure 2 , the present invention comprises the electrode 1-1 and the electrode 2-1 of " V " shape structure that are symmetrically arranged in the insulated airtight shell 5 that is made of alumina ceramics, and the electrode 1-1 and the electrode 2-1 together form two An inward "V"-shaped spark gap 6-1, and an auxiliary ignition device 3-1 made of insulating material with creeping discharge and a thickness of less than 1 mm is respectively provided on the mating surfaces of the electrode 1-1 and the electrode 2-1 1 and 3-1`, between the "V"-shaped spark gap 6-1, there is also an arc extinguishing grid 4- made of metal or ceramic material corresponding to the "V"-shaped spark gap 6-1. 1.

[0017] In this embodiment, the shape of the two electrodes 1-1, 2-1 is designed as a "V" shape structure, and the two electrodes 1-1, 2-1 are placed opposite to each other to form two face-to-face spark gaps 6-1. An auxiliary ignition device 3-1 made of insulating ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com