Minisize diffusion pump and preparation method thereof

A diffusion pump and miniature technology, which is applied in the fields of micro-actuators, transmission, and microfluidic control, can solve the problems of difficult preparation process, complex structure, and application limitations of non-mechanical micro-pumps, and achieve simplified processing and realization of difficulty and drive method, good biocompatibility, and the effect of reducing solid-liquid interface stress and dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

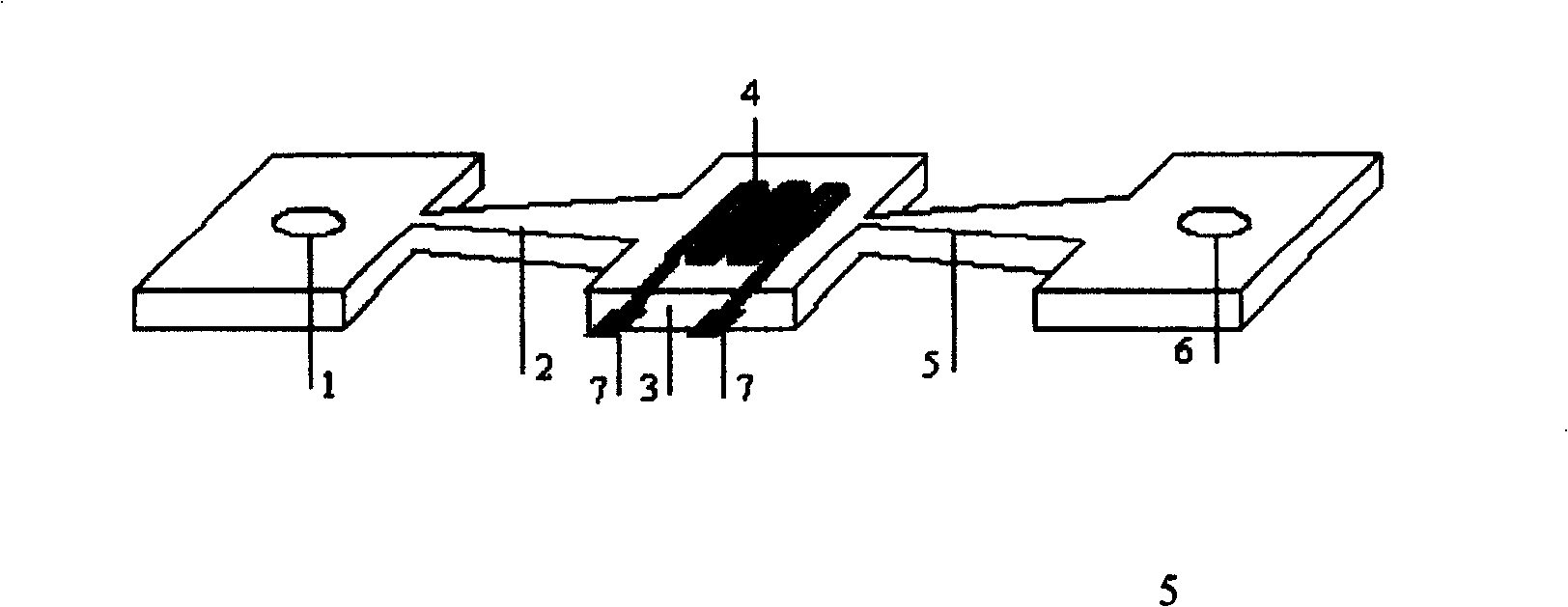

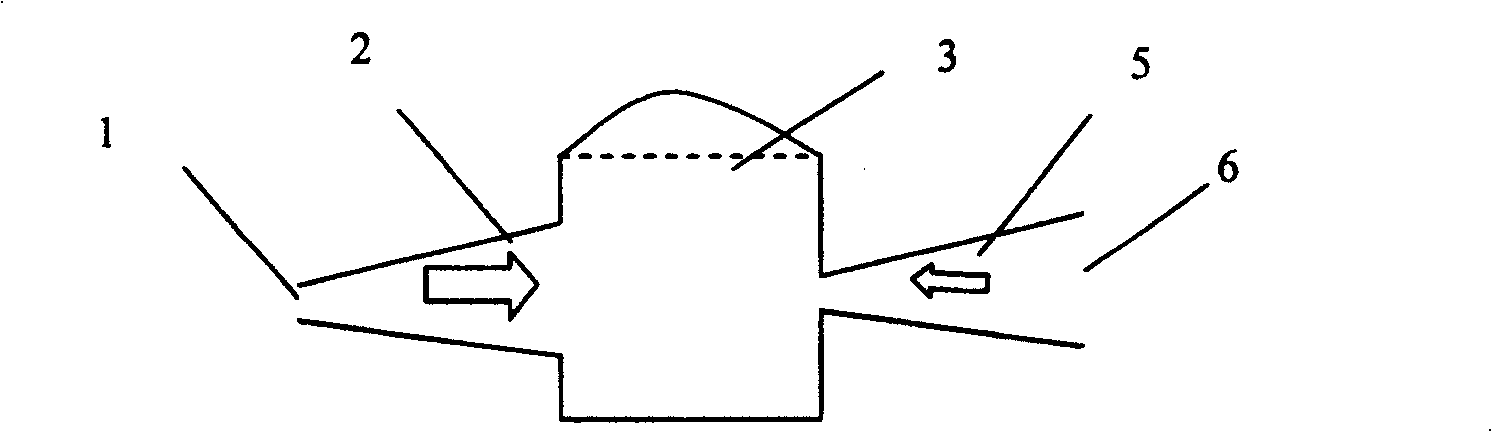

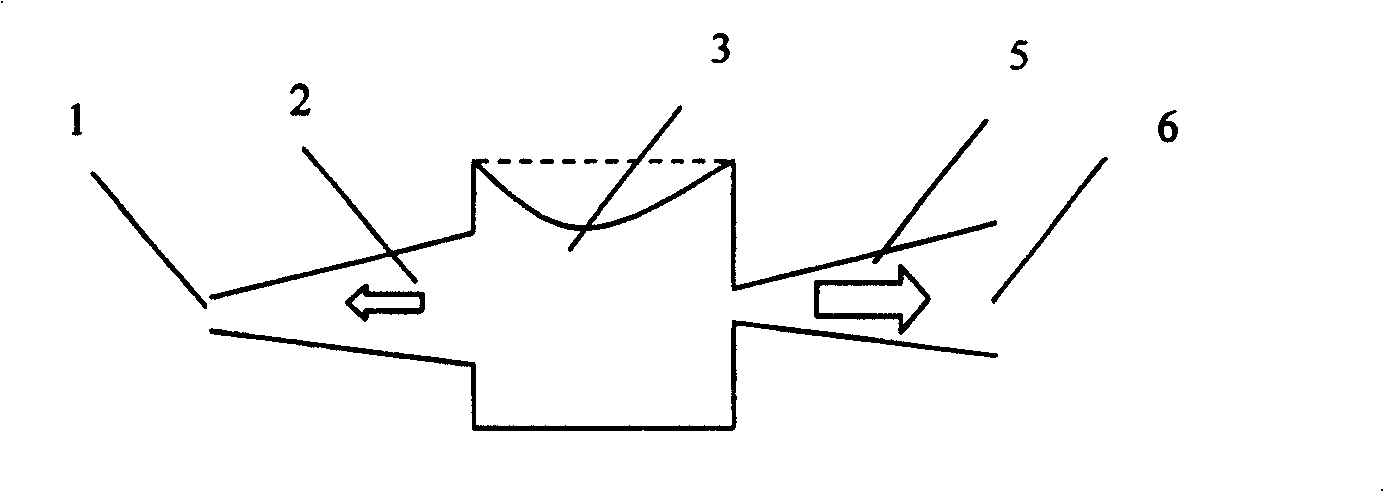

[0042] The micro-diffusion pump provided by the present invention adopts a wedge-shaped diffusion tube as its micro-valve, that is, adopts a wedge-shaped diffusion tube structure with different forward and reverse flow pressure losses. The role of transport fluid. figure 1Schematic diagram of the micro-diffusion pump. It mainly includes: pump inlet 1, inlet diffuser pipe 2, pump chamber 3, outlet diffuser pipe 5, pump outlet 6, driving diaphragm vibration device 4 and electrode 7 in the pump chamber, and diffuser pipe 2 with different forward and reverse flow rates , 5 are respectively arranged between the pump chamber 3 and the pump inlet 1 and outlet 6, the wide mouth of the wedge-shaped diffuser pipe 2 on the side of the pump inlet 1 is connected to the pump chamber 3, and the wedge-shaped diffuser pipe 5 on the side of the pump outlet 6 The narrow mouth is connected with the pump chamber 3. The shape of the pump chamber 3 can be a cylinder, cuboid, cube, prism, etc., and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com