Preparation method of heat-proof modifier for uniform copolymerization

A heat-resistant modifier and uniform technology, applied in the field of resin modifier preparation, can solve the problems affecting polymer gloss and aging resistance, and achieve fast polymerization rate, good compatibility, and uniform copolymerization composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

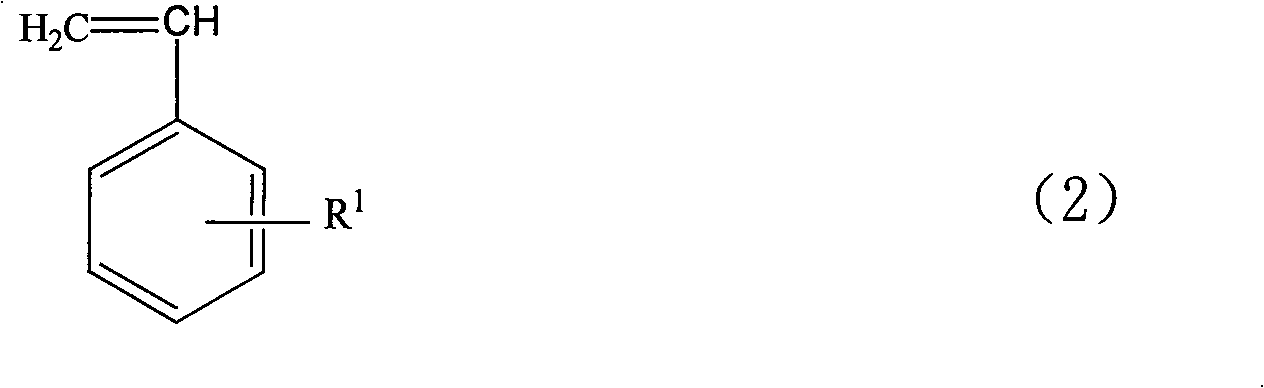

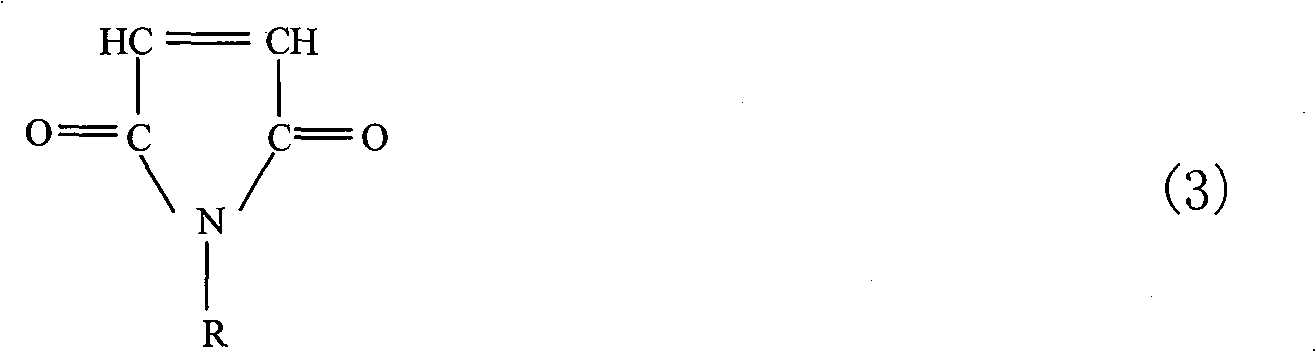

Method used

Image

Examples

specific Embodiment 1

[0063] Add 200g of deionized water, 4g of sodium lauryl sulfate, 0.15g of potassium persulfate, 0.01g of dodecyl mercaptan, 20g of α-methylstyrene, and 30g of acrylonitrile into a 500mL reactor, and fill with nitrogen and exhaust oxygen. , stir to make it evenly mixed to form a stable emulsion. The temperature was raised to 75°C, and a solution containing 10g of N-phenylmaleimide and 40g of styrene was added dropwise at a rate of 15mL / h for 3.5h, keeping the reaction temperature at 75°C. After the dropwise addition was completed, the reaction was continued for 1 h, and the temperature was raised to 85° C. for aging for 2 h. After the reaction, use 3mmol / L aluminum sulfate solution at 90°C to break the emulsion, wash and dry to obtain a white powdery polymer with a conversion rate of over 99% and a glass transition temperature of 140°C.

specific Embodiment 2

[0079] Add 200g of deionized water, 2g of sodium dodecylbenzenesulfonate, 0.5g of ammonium persulfate, 0.2g of dodecyl mercaptan, 20g of α-methylstyrene, and 20g of styrene into a 500mL reactor, and fill with nitrogen Oxygen release, stirring to make it evenly mixed to form a stable emulsion. The temperature was raised to 75°C, and a solution containing 10g of N-cyclohexylmaleimide, 20g of styrene, and 30g of methyl methacrylate was added dropwise at a rate of 15mL / h for 4 hours, and the reaction temperature was kept at 75°C. After the dropwise addition was completed, the reaction was continued for 1 h, and the temperature was raised to 85° C. for aging for 2 h. After the reaction, use 3mmol / L aluminum sulfate solution at 90°C to break the emulsion, wash and dry to obtain a white powdery polymer with a conversion rate of over 99% and a glass transition temperature of 139°C.

specific Embodiment 3

[0083] Add 200g of deionized water, 0.8g of sodium lauryl sulfate, 0.1g of potassium persulfate, 0.1g of carbon tetrachloride, 2g of α-methylstyrene, and 3g of acrylonitrile into a 500mL reactor, fill with nitrogen and exhaust oxygen, Stir to mix well to form a stable emulsion. The temperature was raised to 80°C, and a solution containing 1g of N-phenylmaleimide and 4g of styrene was added dropwise at a rate of 5mL / h for 1h, and the reaction temperature was kept at 80°C. After the dropwise addition was completed, the reaction was continued for 4 hours, and the temperature was raised to 95°C for aging for 2 hours. After the reaction, use 90°C 3mmol / L aluminum sulfate solution to break the emulsion, wash and dry to obtain a white powdery polymer with a conversion rate of about 80% and a glass transition temperature of 134°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com