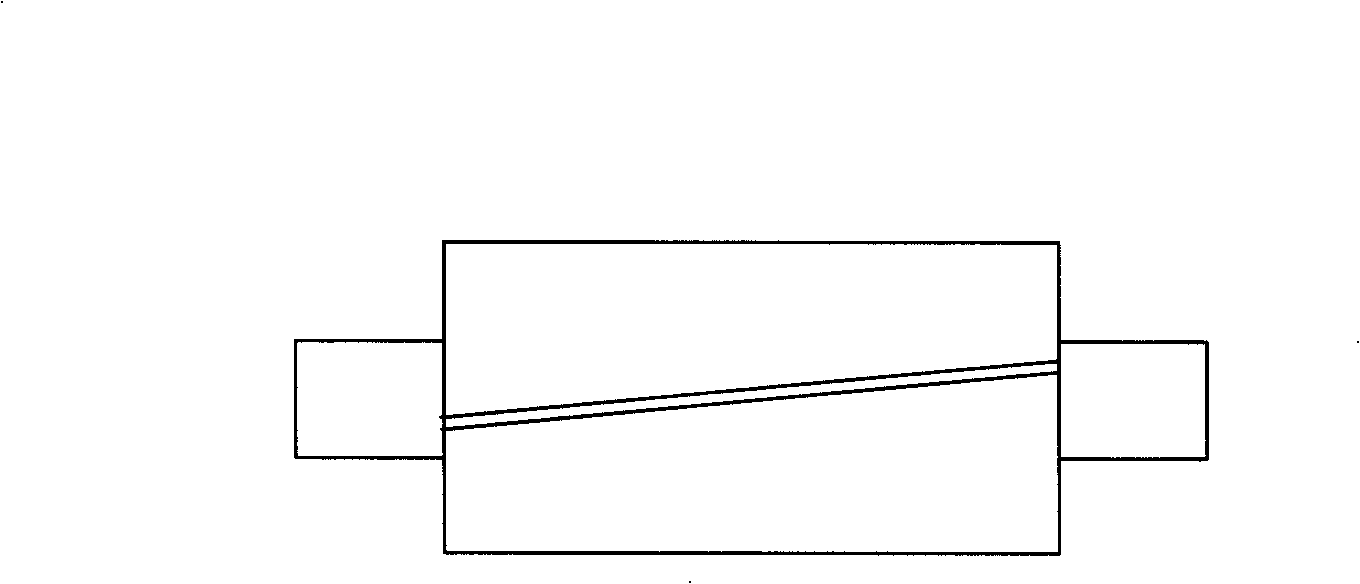

Inclined open technology of single sheet paper gravure machie printing plate rotary drum and flat sheet type gravure technology

A manufacturing method and plate cylinder technology, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of low line-to-wall ratio, complicated gravure cylinder manufacturing process, and expensive investment equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The production process of the flat sheet type intaglio plate used in the present invention adopts the frequency modulation and amplitude modulation hybrid net hanging net technique to replace the previous square grid technique.

[0022] The advantage of this solution is that it can make the level of the image richer. In the past, the dark tone level of the square grid was generally 55%, but now it can be increased to 80%-85%, which greatly enriches the color saturation and product quality. The three-dimensional sense can increase the line-to-wall ratio from less than 3 to 9-12.

[0023] The present invention provides a brand-new gravure printing plate, which is a piece of metal aluminum, copper or multilayer metal composite plate material, (iron-copper, aluminum-copper) material as the plate base, and then on the copper (thickness is 0.3-0.5mm), apply a layer of photosensitive coating (2g-4g / m) that is sensitive to ultraviolet light, and cover the film separation film that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com