Precharging technique for forming nickel hydrogen battery

A nickel-metal hydride battery and pre-charging technology, which is applied in secondary battery charging/discharging, alkaline storage battery electrodes, alkaline storage batteries, etc., can solve problems such as battery capacity loss, reduce AC internal resistance and DC internal resistance, and delay Effect of OCV drop speed and improvement of shelf life performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

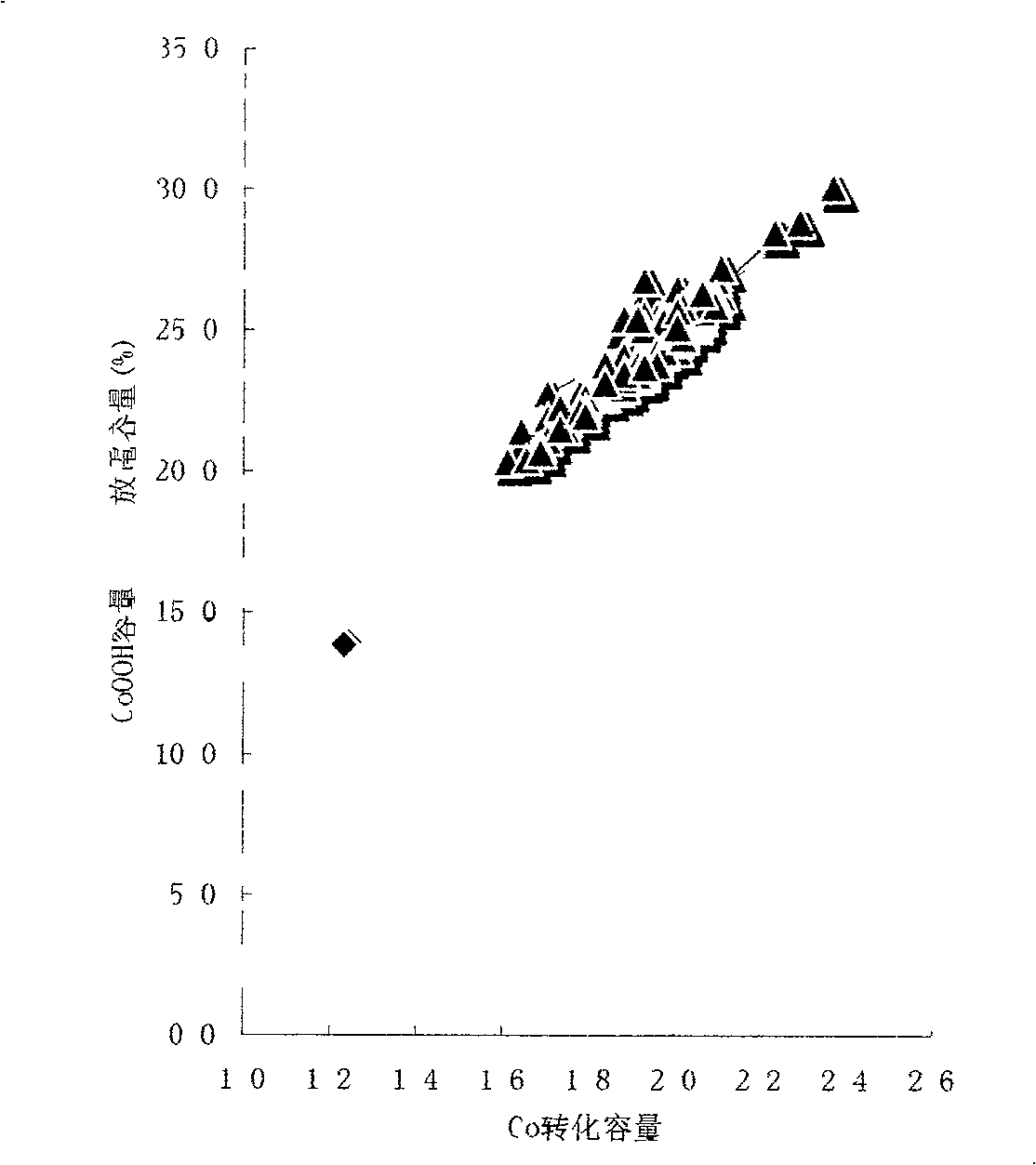

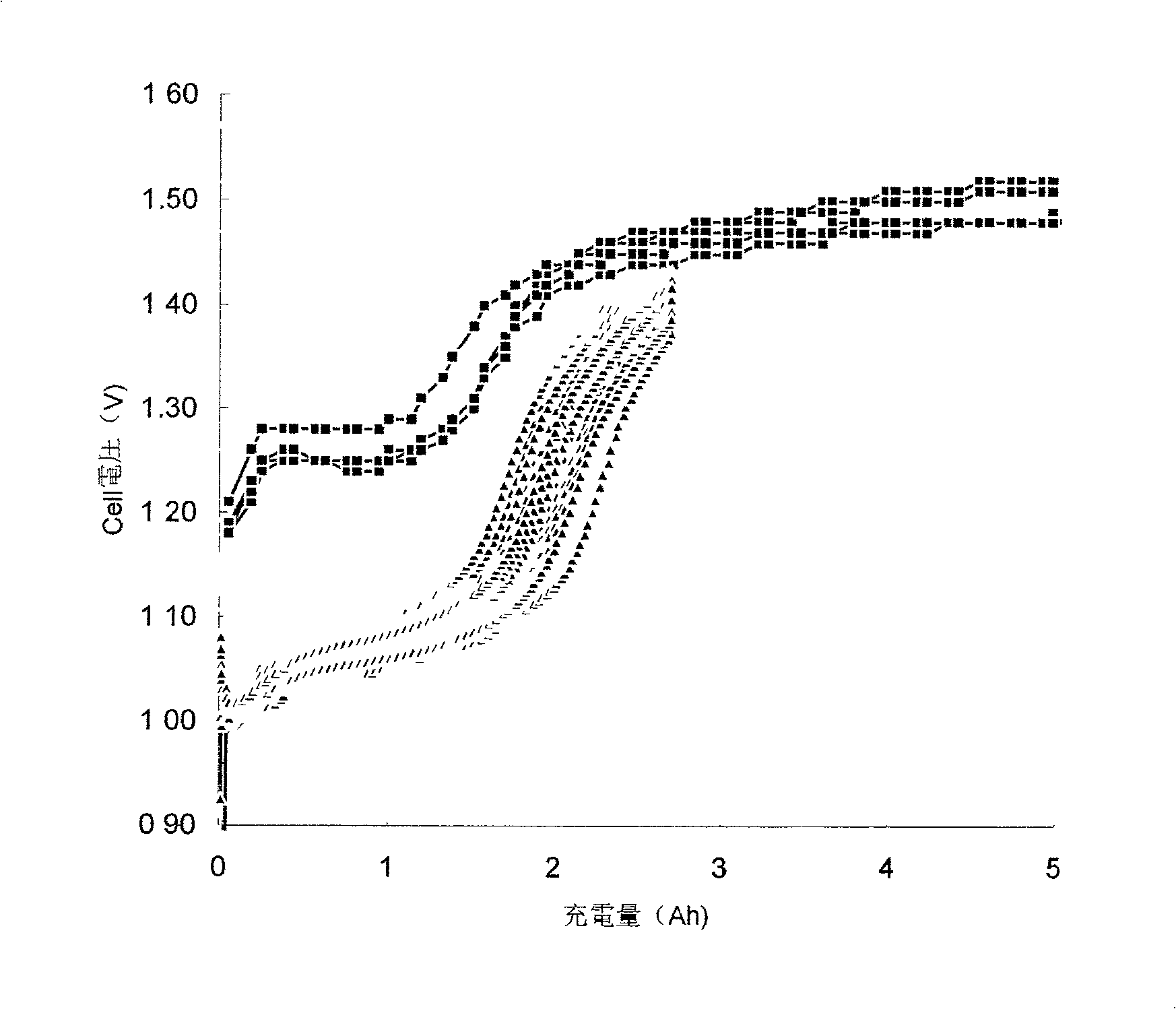

[0036] The nickel-hydrogen battery formation method of the present invention comprises the following steps: 1. provide the assembled nickel-hydrogen battery, and this battery comprises Ni(OH) 2 The positive plate composed of Co(II) compound, ②5 hours after assembly, the current density is ≤20mA / cm 2 (refers to the precharge relative to the positive plate area). ③The positive plate of the battery contains substances capable of redox reversible reactions, such as Ni(OH) 2 . The positive plate preferably comprises a nickel foam substrate, and the cell can be assembled using any conventional assembly technique, Ni(OH) 2 It can contain Co, Zn, Mn, Al and other element doping, and the nickel foam substrate preferably has a PPI of 80-110. Once the battery assembly is completed, the battery is stored at no lower than room temperature for about 3 to 8 hours, and then a pre-charging process is performed, followed by a 16-hour shelf life at no lower than room temperature. During this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com