Solid super acidic catalyst and its preparing method

A solid superacid and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of reduced activity of solid superacids, decreased catalyst activity, and reduced specific surface area, etc., to achieve increased Content, increase the calcination temperature, improve the effect of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

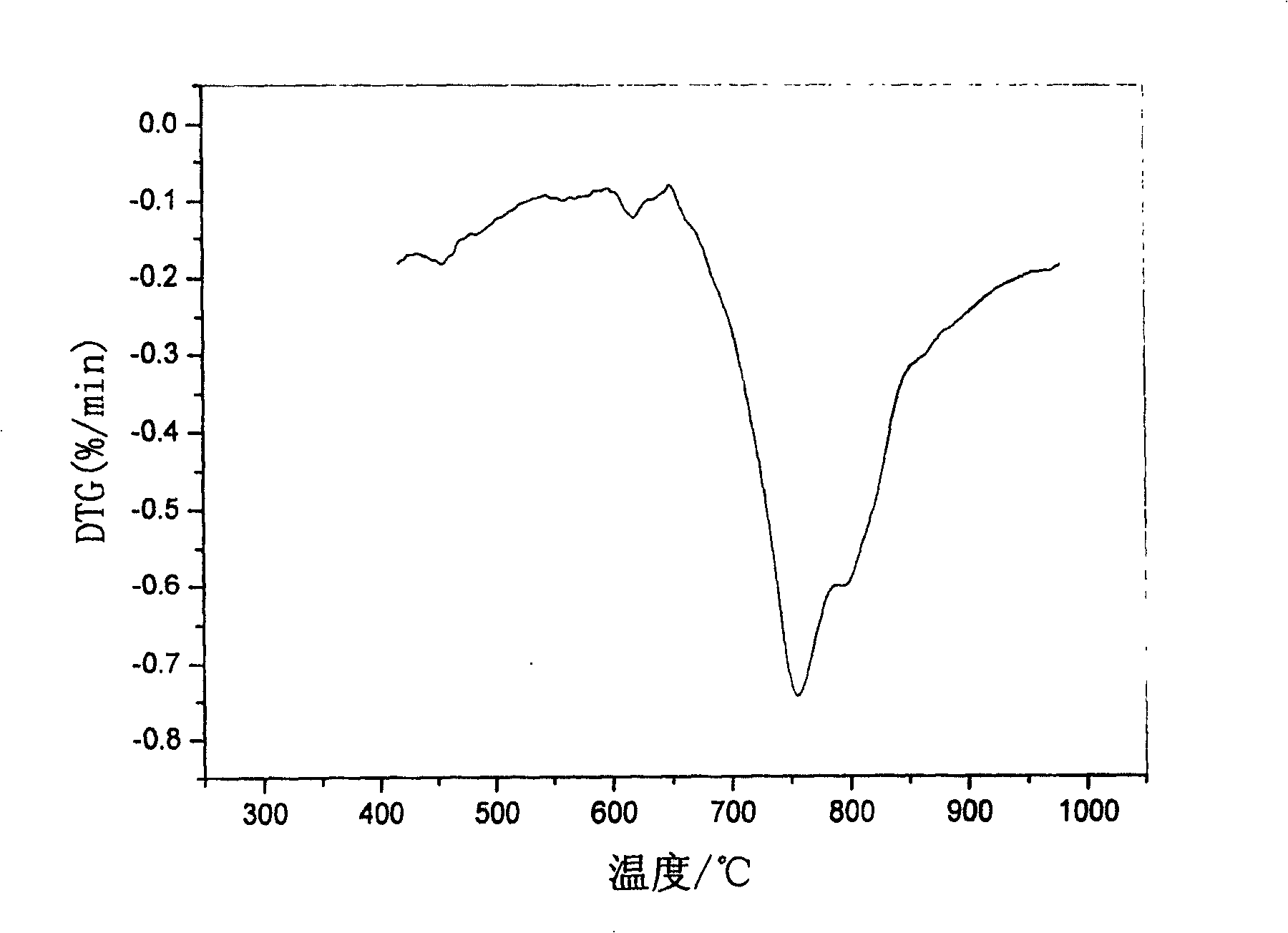

Image

Examples

Embodiment 1

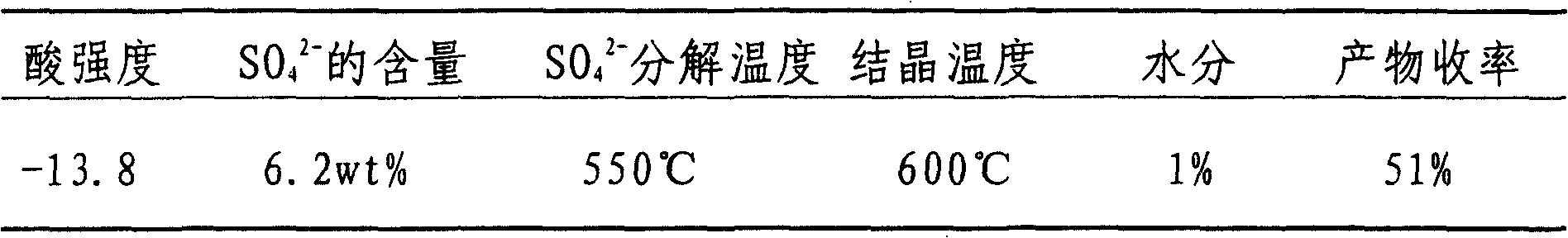

[0019] Add water to dissolve the zirconium oxychloride, adjust the pH value of the solution to a range of 9 with ammonia water, and generate zirconium hydroxide precipitates. The precipitate was filtered and washed until the filtrate had a pH of 7 and no Cl - , and then the precipitate was dried. Combine the precipitate with AlF 3 The powder mixture is ground to 3 The content of powder is 1wt%), impregnated with 0.5mol / L sulfuric acid solution, filtered and dried. After drying, the mixture was calcined at 600°C for 5 hours. The properties and product yields of the resulting catalysts are shown in Table 2. Table 2

[0020]

Embodiment 2

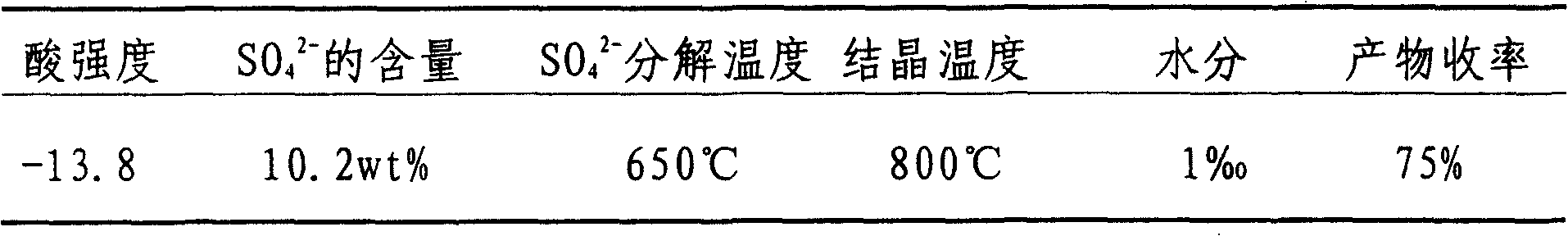

[0022] Catalyst is prepared by the method of embodiment 1, difference is that in the mixture AlF 3 The content is 3wt%, and the properties and product yield of the obtained catalyst are shown in Table 3. table 3

[0023]

Embodiment 3

[0025] Catalyst is prepared by the method of embodiment 1, difference is that in the mixture AlF 3 The content is 5wt%, and the properties and product yield of the obtained catalyst are shown in Table 4. Table 4

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com