Pre-deoxygenated synthetic pellet for steel making in electric arc furnace and its making process

A pre-deoxidation and electric arc furnace technology is applied in the field of deoxidizer with slag in the electric arc furnace steelmaking furnace, which can solve the problems of high consumption of deoxidizer alloy, increase production cost, reduce steel purity and other problems, so as to reduce the consumption of deoxidizer, The effect of improving the yield of alloy and reducing the burden of deoxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

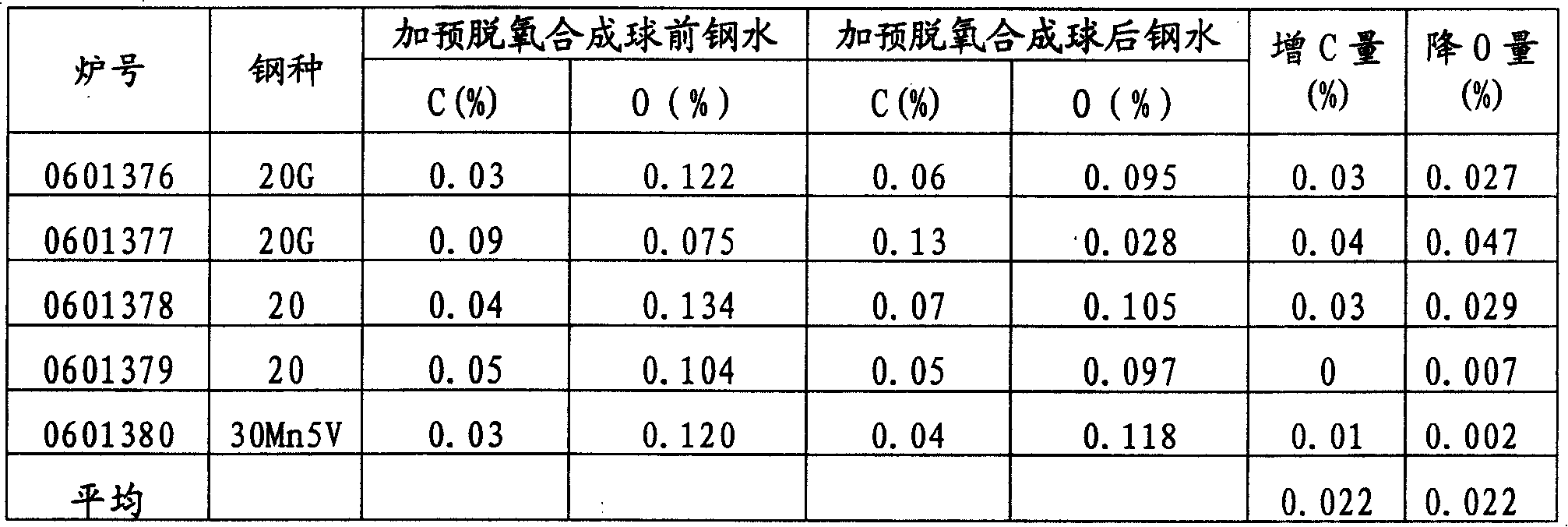

Examples

Embodiment Construction

[0019] 1. Source of raw materials

[0020] The raw materials of the electric arc furnace steelmaking pre-deoxidation synthetic balls are all commercially available products, which can be purchased directly from the market.

[0021] 2. The weight percentage of each raw material in the electric arc furnace steelmaking pre-deoxidation synthetic ball batching:

[0022] Calcined petroleum coke with carbon content ≥ 98.5% 26%,;

[0023] Steel grit with iron content ≥ 96%, phosphorus content < 0.11% and sulfur content < 0.04% 70%;

[0024] Composite binder composed of 90% sodium silicate and 10% industrial starch by weight percentage 3%;

[0025] Graphite powder 1%.

[0026] 3. the manufacture method of above-mentioned electric arc furnace steelmaking pre-deoxidation synthetic ball comprises the following steps successively:

[0027] (1) finely crushing: using a pulverizer to crush the calcined petroleum coke into a fine powder whose particle size is below 1 mm;

[0028] (2) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com