Control cable for nuclear power station

A technology for controlling cables and nuclear power plants. It is applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc. It can solve the problems of not being able to meet the thermal life at the same time, achieve high flame retardancy, and ensure safe shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

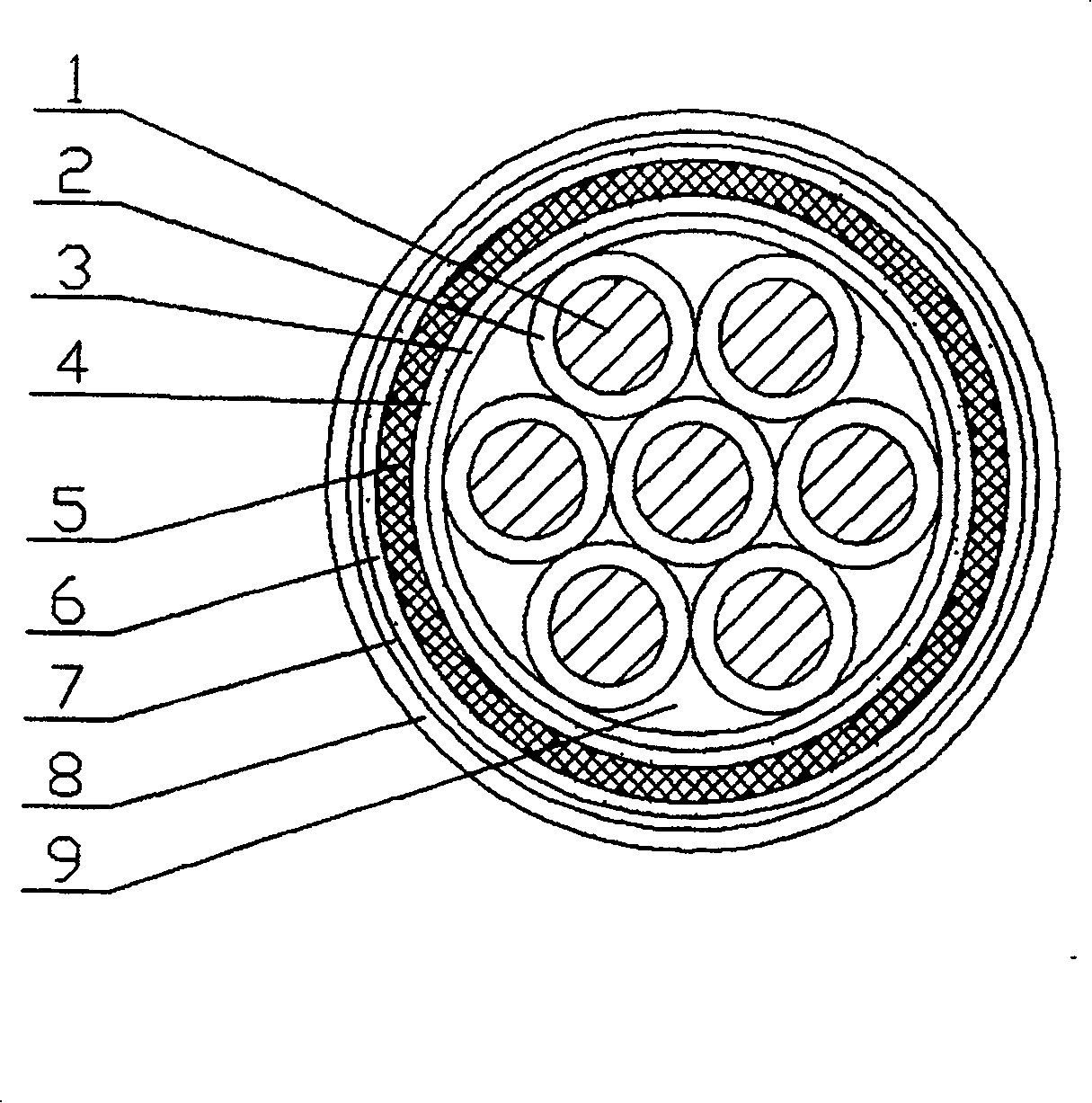

[0008] The present invention has many (2-49) wire cores, each wire core has a conductor 1 inside, and the outside of the conductor 1 has an insulating layer 2; during manufacture, the wire cores are first manufactured to bundle multiple wire cores , wrapping tape 3 on the outside of the wire core bundle, filling filler 9 between the wire cores and inside the tape 3, and covering the outside of the tape 3 with a flame-retardant glass ribbon layer 4, which is characterized in that it is flame-retardant The glass ribbon layer 4 is coated with a tinned copper wire braided shielding layer 5, glass ribbon layer 6 and wrapping tape 7, and then the outermost layer is coated with an outer sheath 8, and the outer sheath 8 is cross-linked with an electron beam. The dose of the electron beam used was 8-16 Mrad. The insulating layer 2 is double-layered, one of which is made of high flame-retardant, high-strength material, low-smoke, and halogen-free irradiation cross-linked polyethylene, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com