Control system and control method for preventing overpressure of main steam pipeline of nuclear power plant

A main steam and nuclear power plant technology, applied in the field of nuclear safety, can solve the problems of overpressure in the main steam pipeline and the inability of steam to be completely removed in time, and achieve the effects of ensuring discharge time, preventing overpressure and ensuring safe shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

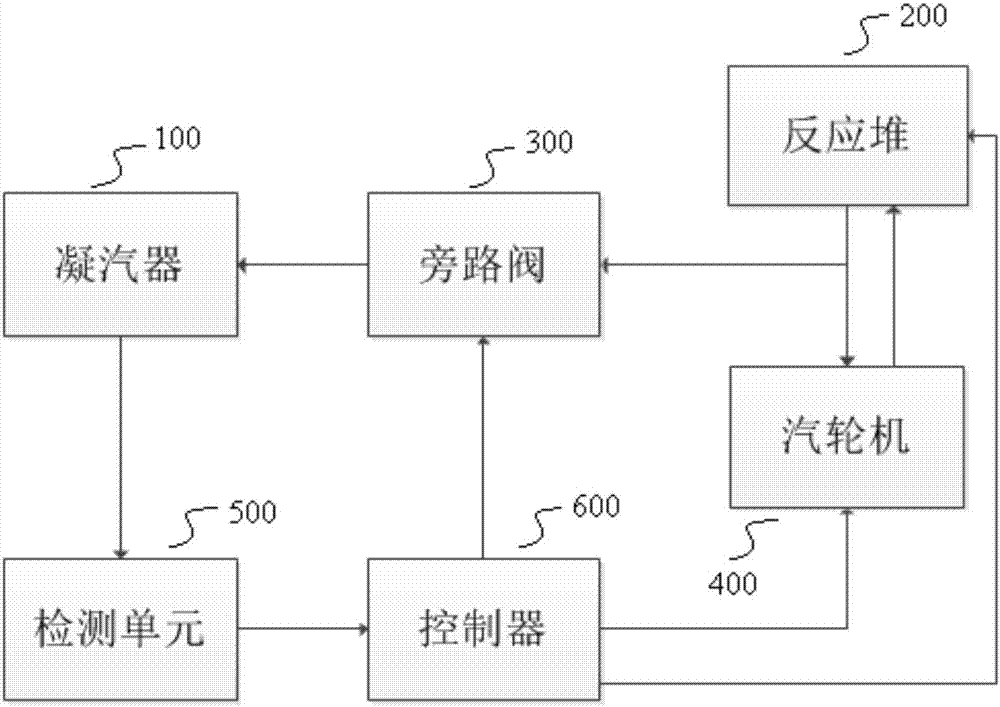

[0049] An embodiment of the present invention provides a control system for preventing overpressure of the main steam pipeline of a nuclear power plant, see figure 1 , the system consists of:

[0050] Condenser 100, the condenser 100 is connected to the pipeline where the bypass valve 300 is located, and the condenser 100 is used to condense the high-temperature steam discharged from the bypass valve;

[0051] Bypass valve 300, which is installed on the pipeline where the main steam pipeline is connected to the condenser 100;

[0052] The condenser pressure detection unit 400 is installed on the condenser 100 to obtain the actual pressure signal in the condenser 100; the condenser pressure detection unit is a pressure sensor, and the pressure sensor can be selected as ROSEMOUNT3051.

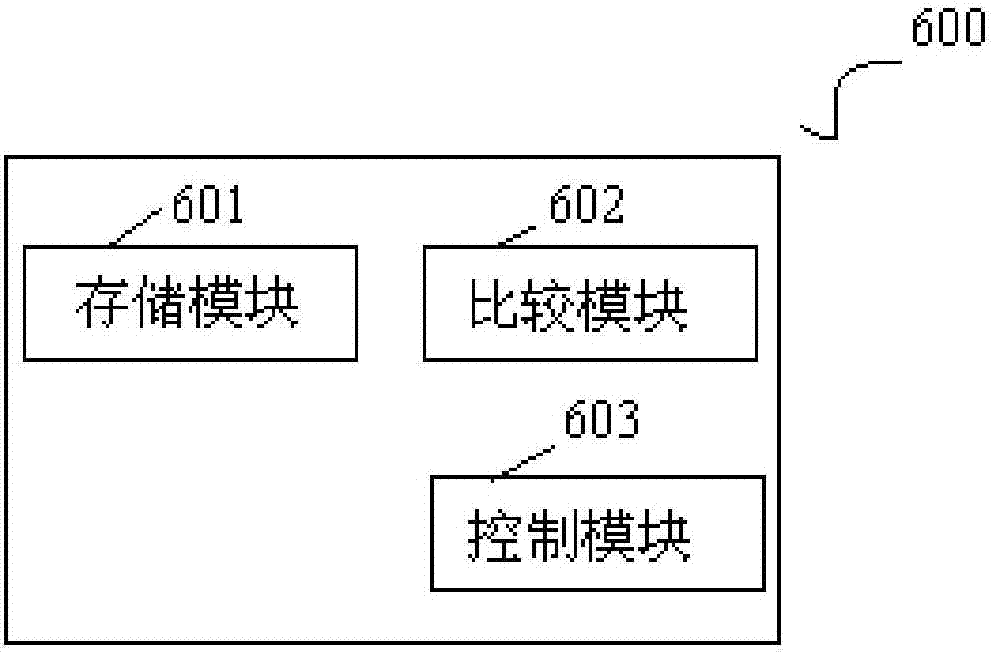

[0053] The controller 600 is electrically connected to the condenser pressure detection unit 100, the steam turbine 400, the reactor 200 and the bypass valve 300 respectively, and the controller...

Embodiment 2

[0115] An embodiment of the present invention provides a control method for preventing overpressure of the main steam pipeline of a nuclear power plant, see Image 6 , the method includes:

[0116] Step S100, acquiring the actual pressure signal in the condenser 100 through the condenser pressure detection unit 500 installed on the condenser 100;

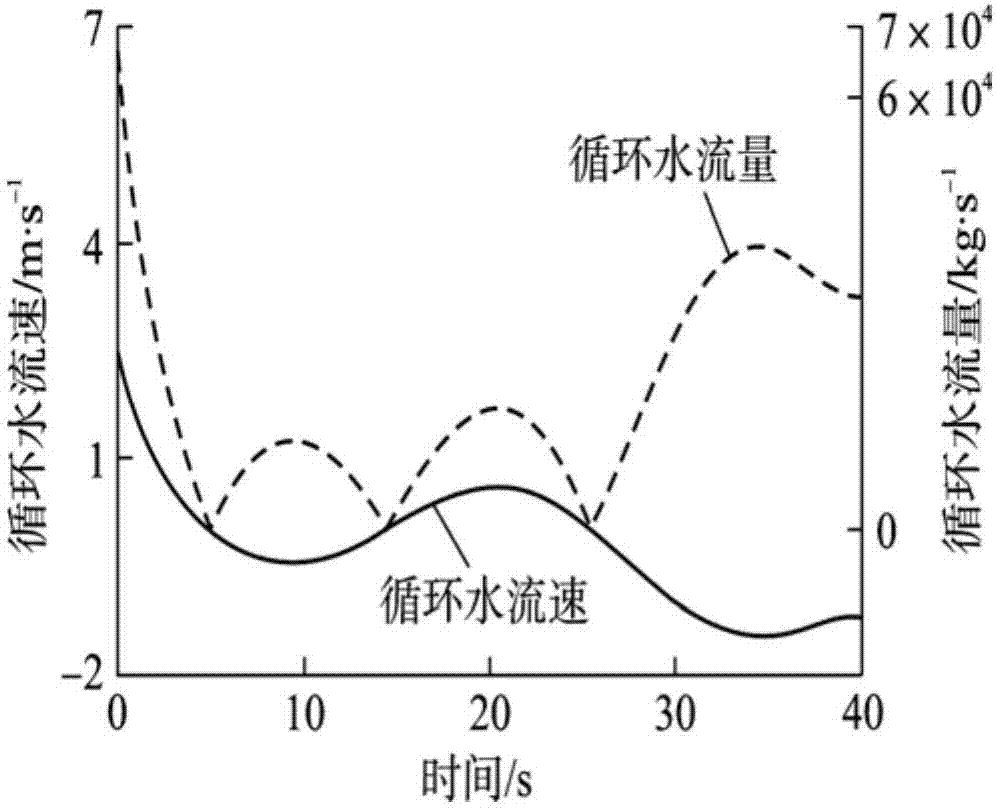

[0117] Step S200, the controller judges whether the detected actual pressure signal satisfies the first preset condition and the second preset condition; the first preset condition in the figure is that the fixed value of the condenser pressure is greater than or equal to 26kPa.a as an early intervention Value, the intervention value is defined as the condenser fault signal, when the condenser pressure value reaches 26kPa.a, the condenser fault signal is triggered, sent to the nuclear island to protect the stack and open the bypass discharge; the second preset condition is The pressure signal of the condenser is not available, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com