Manufacture method of linear low density polyethylene lawn-shape ground cushion

A linear low density, polyethylene technology for use in household components, applications, home appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

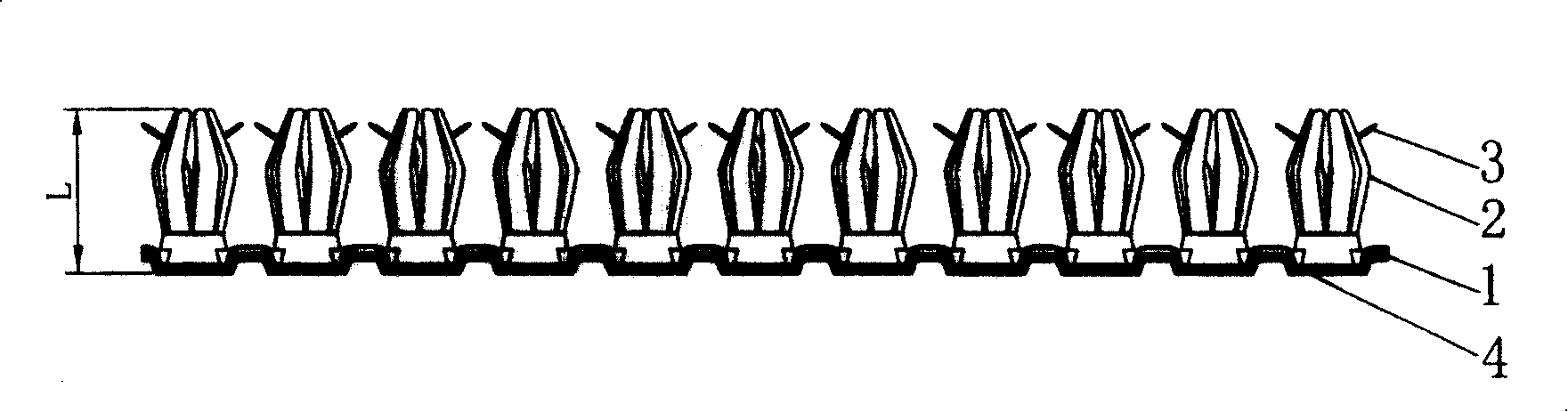

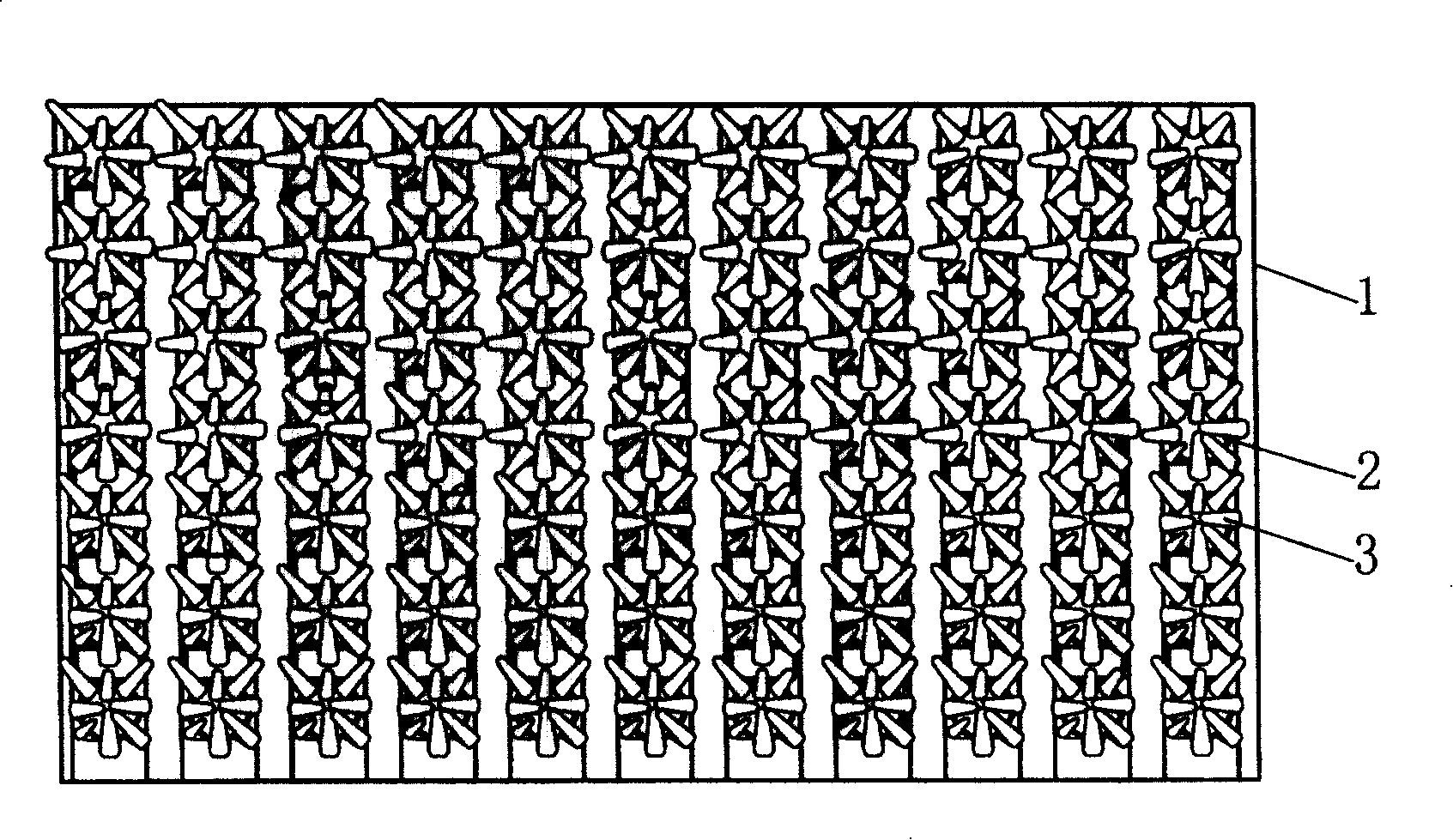

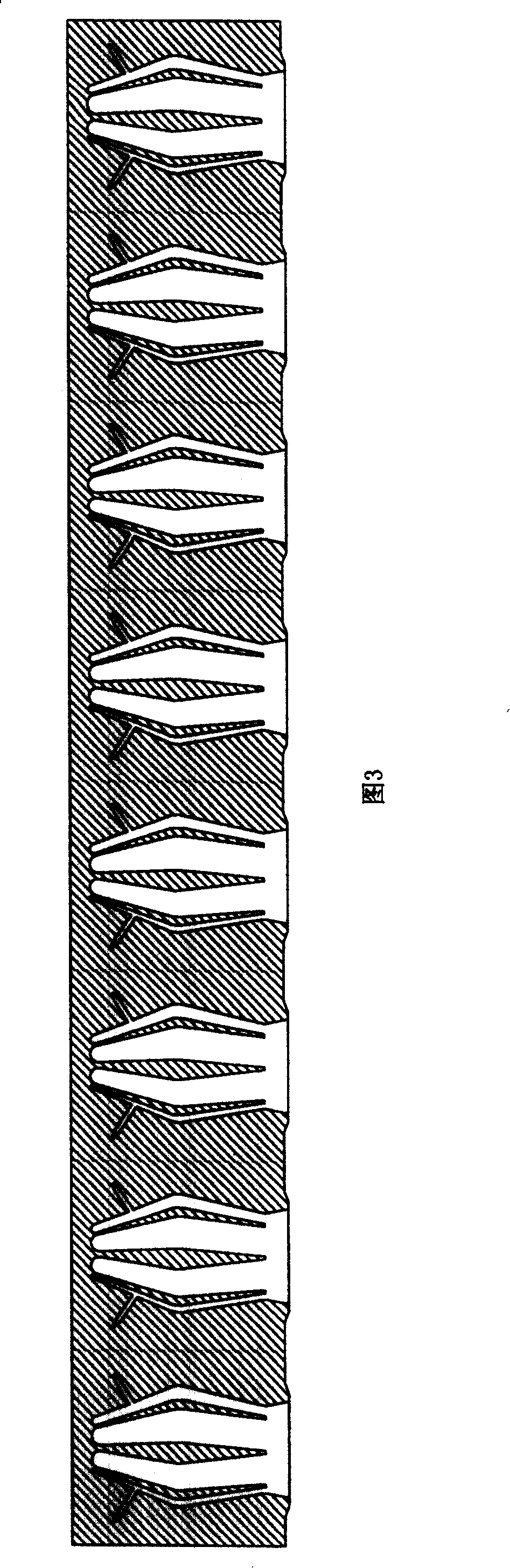

Image

Examples

Embodiment 1

[0027] The linear low-density polyethylene (LLDPE, 7047) is used as raw material, and industrial pigment (reduced bright green FFB) is added, and the added amount accounts for 0.8% of the linear low-density polyethylene (LLDPE) according to the weight percentage.

[0028] The processing steps are as follows:

[0029] The raw materials are stirred, and the raw materials are respectively added into a high-speed mixer, stirred and mixed, and the stirring speed is 5000 rpm, and the time is 50 minutes.

[0030] High temperature and high pressure injection molding. Put the mixed raw materials into a high-temperature and high-pressure injection molding machine, and perform injection molding at a temperature of 180° C. and a pressure of 2 MPa.

[0031] Injection molding. The injection molding material is added to the mold cast according to the shape of the product, and is shaped by the mold.

[0032] Composite, bonding non-woven fabric and heat-resistant non-slip mesh on the bottom...

Embodiment 2

[0037] The linear low-density polyethylene (LLDPE, 7540) is used as raw material, and industrial pigment (reduced olive green B) is added, and the added amount accounts for 0.01% of the linear low-density polyethylene (LLDPE) according to the weight percentage.

[0038] The processing steps are as follows:

[0039] The raw materials are stirred, and the raw materials are respectively added into a high-speed mixer, stirred and mixed, and the stirring speed is 1000 rpm, and the time is 150 minutes.

[0040] High temperature and high pressure injection molding. Put the mixed raw materials into a high-temperature and high-pressure injection molding machine, and perform injection molding at a temperature of 170° C. and a pressure of 0.5 MPa.

[0041] Injection molding. The injection molding material is added to the mold cast according to the shape of the product, and is shaped by the mold.

[0042] Composite, bonding non-woven fabric and heat-resistant non-slip mesh on the botto...

Embodiment 3

[0047] The linear low-density polyethylene (LLDPE, 7042) is used as a raw material, and an industrial pigment (phthalocyanine green G) is added, and the added amount accounts for 2% of the linear low-density polyethylene (LLDPE) according to the weight percentage.

[0048] The processing steps are as follows:

[0049] The raw materials are stirred, and the raw materials are respectively added into a high-speed mixer, and stirred and mixed at a stirring rate of 10000 rpm for 5 minutes.

[0050] High temperature and high pressure injection molding. Put the mixed raw materials into a high-temperature and high-pressure injection molding machine, and inject them under the conditions of a temperature of 190° C. and a pressure of 5 MPa.

[0051] Injection molding. The injection molding material is added to the mold cast according to the shape of the product, and is shaped by the mold.

[0052] Composite, bonding non-woven fabric and heat-resistant non-slip mesh on the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com