Isolating gun bore pressure testing system and testing method

A pressure test and isolation technology, applied in the direction of signal transmission system, electrical signal transmission system, non-electrical signal transmission system, etc., can solve the problems of test instrument damage, insulation layer breakdown, test instrument not working properly, etc., to achieve low Effects of power consumption, ensuring real-time transmission, and ensuring practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. Isolated bore pressure test system and test method

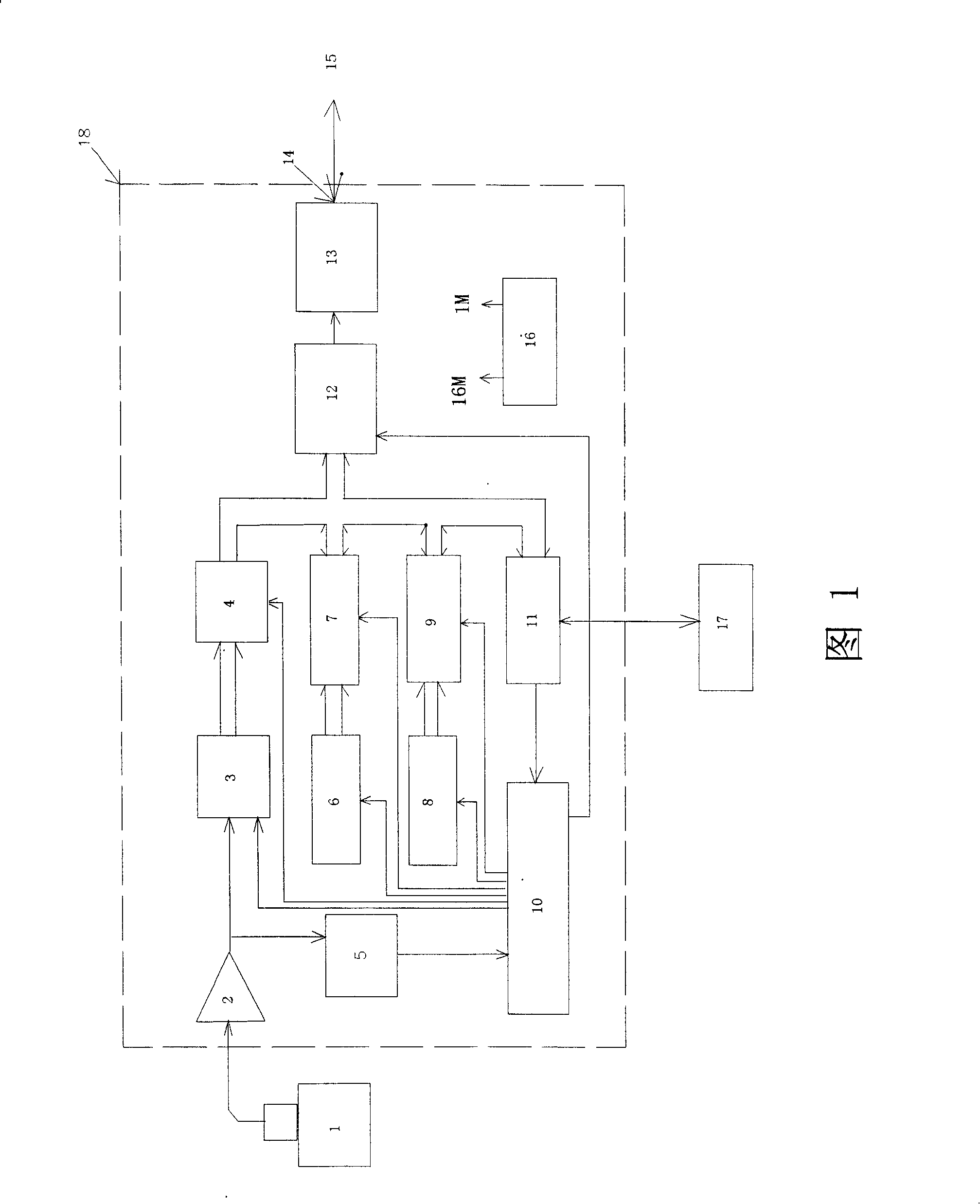

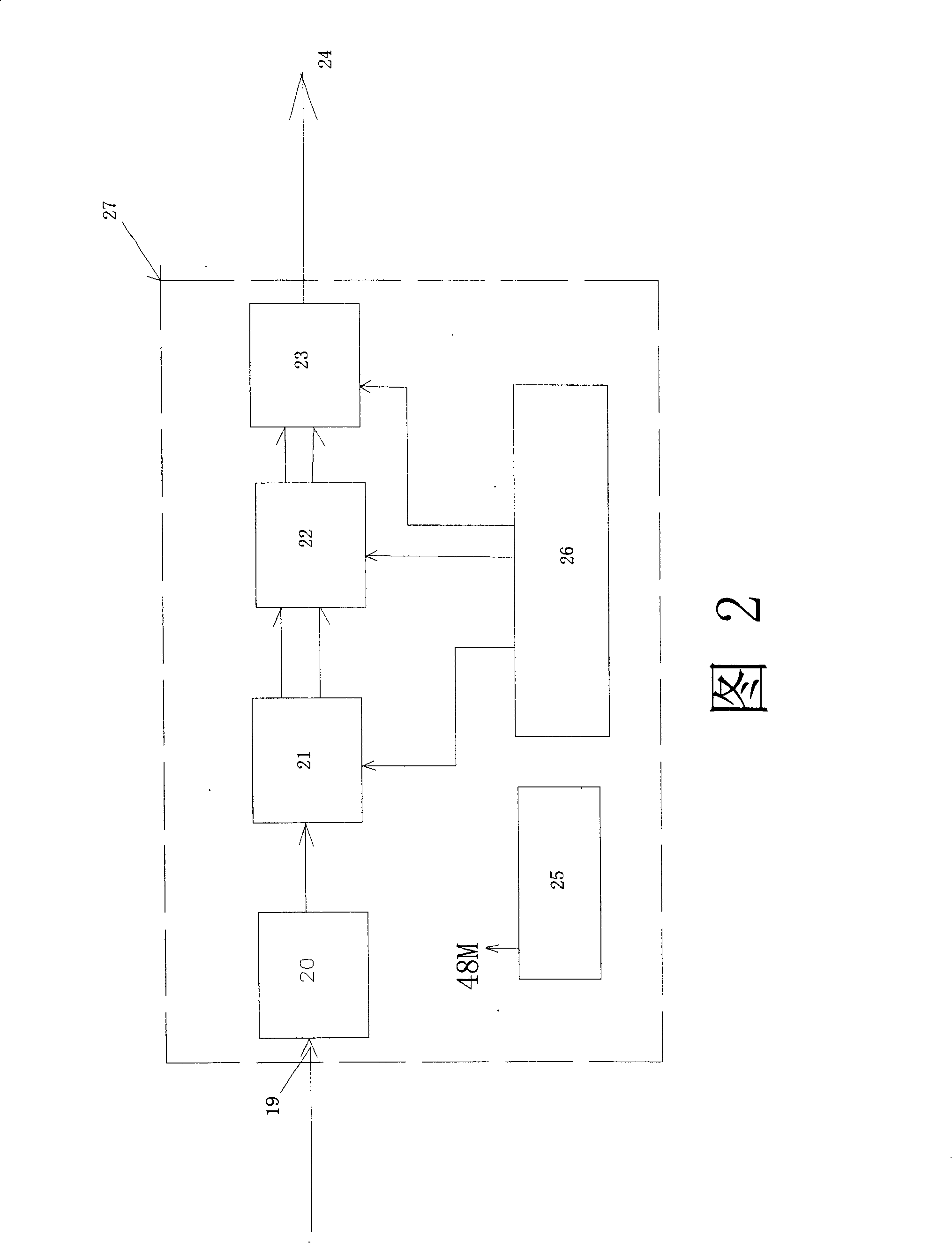

[0030] The specific structure of the isolated gun bore pressure test system in this example is shown in Figure 1- Figure 9 Jointly shown. The system includes the information collection and processing part of the gun bore pressure, the information transmission part and the information receiving part. Wherein the information acquisition and processing part of the gun bore pressure is an isolated gun bore pressure testing device, which is composed of the housing 18 and the inner gun bore pressure information acquisition circuit, information processing circuit, information output circuit and their auxiliary circuits and control software Function connection composition, what Fig. 1 shows is the block diagram of the circuit structure of isolation type gun bore pressure testing device, wherein information acquisition circuit has the piezoelectric sensor 1 of information acquisition, information amplification ...

Embodiment 2

[0032] Embodiment 2. Isolated type gun bore pressure testing system and testing method

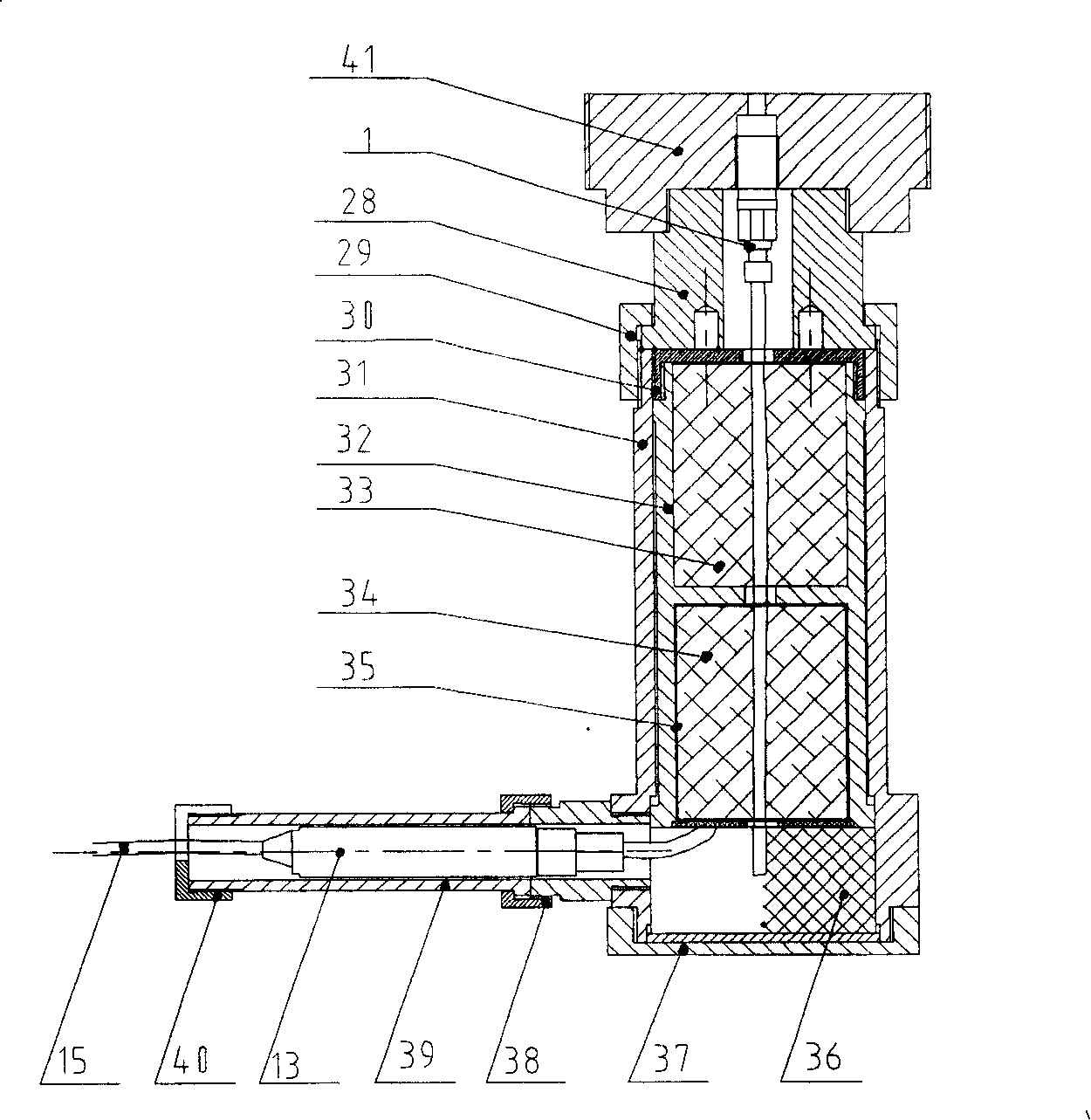

[0033] The specific structure of the isolated type gun bore pressure testing system of this example is shown in Fig. 1~ Figure 9 Jointly shown. The system includes the information collection and processing part of the gun bore pressure, the information transmission part and the information receiving part. Wherein the information collection and processing part of the gun bore pressure is an isolated gun bore pressure test device, and Fig. 1 shows a block diagram of the circuit structure of the isolated gun bore pressure test device, image 3 Then show the sectional view of the physical structure of the isolated type gun bore pressure testing device of this example, the device includes the information acquisition circuit, information processing circuit, information output circuit and their auxiliary circuits and control of the gun bore pressure assembled in the housing 18 and software. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com