Preparation method of hydroxy phosephorite hollow microball

A technology of hydroxyapatite and hollow microspheres, which is applied in the field of preparation of hydroxyapatite microspheres, can solve the problems of difficult large-scale adjustment, high crystallinity of microspheres, complicated process, etc., and achieve simple and easy process operation , large specific surface area and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

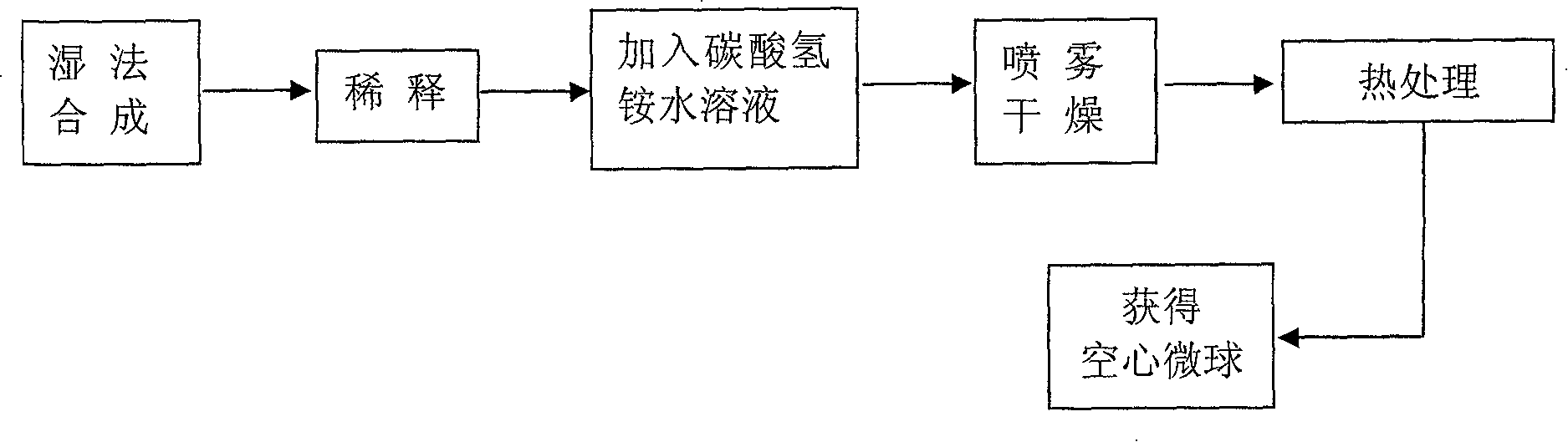

Method used

Image

Examples

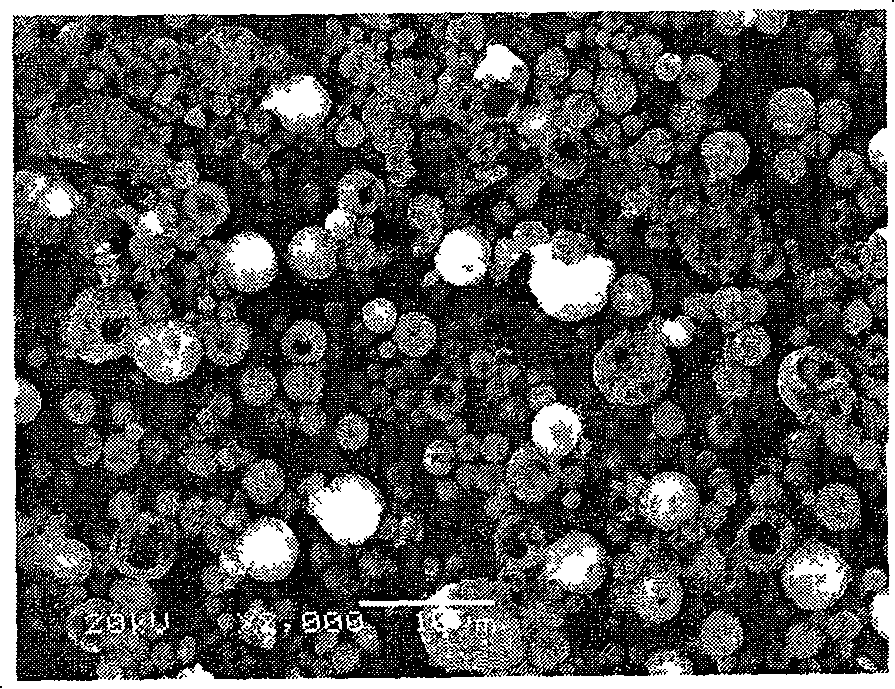

Embodiment 1

[0033] (1) Calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) and diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) as raw material, according to the ratio of calcium to phosphorus molar ratio of 1.67, the hydroxyapatite slurry is prepared by the chemical precipitation method in the wet method, wherein Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The ratio of the mass (g) to the volume (ml) of the final obtained slurry is: 2.98: 1: 17, and the specific chemical reaction formula is:

[0034] 10Ca(NO 3 ) 2 +6(NH4 ) 2 HPO 4 +8NH 4 OH→Ca 10 (PO 4 ) 6 (OH) 2 +20NH 4 NO 3 +6H 2 o

[0035] (2) Dilute the hydroxyapatite slurry with distilled water at a ratio of 5:1 by volume ratio, and add ammonium bicarbonate at a concentration of 0.03 g / ml based on the volume of the diluted hydroxyapatite slurry , mix and stir evenly;

[0036] (3) Under the magnetic stirring speed of 400 rev / min, the above mixed solution is sprayed under the condition that the nozzle diameter is 1mm,...

Embodiment 2

[0042] (1) Calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) and diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) as raw material, according to the ratio of calcium to phosphorus molar ratio of 1.67, the hydroxyapatite slurry is prepared by the chemical precipitation method in the wet method, wherein Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The ratio of the mass (g) to the volume (ml) of the final obtained slurry is: 2.98: 1: 17, and the specific chemical reaction formula is:

[0043] 10Ca(NO 3 ) 2 +6(NH 4 ) 2 HPO 4 +8NH 4 OH→Ca 10 (PO 4 ) 6 (OH) 2 +20NH 4 NO 3 +6H 2 o

[0044] (2) Dilute the hydroxyapatite slurry with distilled water at a ratio of 5:1 by volume ratio, and add ammonium bicarbonate at a concentration of 0.01 g / ml based on the volume of the diluted hydroxyapatite slurry , mix and stir evenly;

[0045] (3) At a magnetic stirring speed of 350 rev / min, spray the above-mentioned mixed solution with a nozzle diameter of 1 mm, an inlet air tempe...

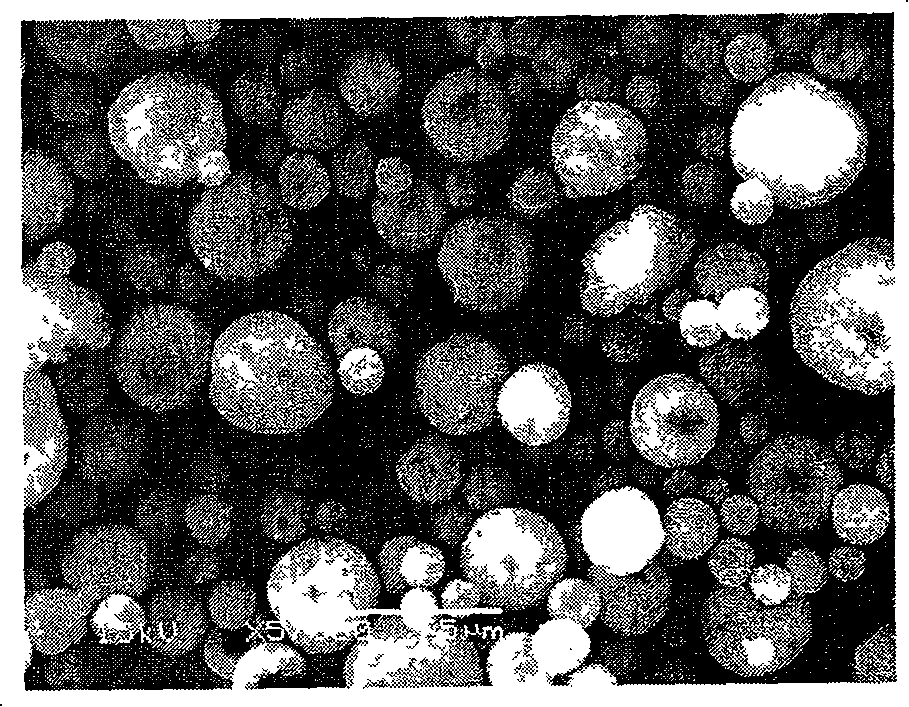

Embodiment 3

[0049] (1) Calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) and diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) as raw material, according to the ratio of calcium to phosphorus molar ratio of 1.67, the hydroxyapatite slurry is prepared by the chemical precipitation method in the wet method, wherein Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The ratio of the mass (g) to the volume (ml) of the final obtained slurry is: 2.98: 1: 17, and the specific chemical reaction formula is:

[0050] 10Ca(NO 3 ) 2 +6(NH 4 ) 2 HPO 4 +8NH 4 OH→Ca 10 (PO 4 ) 6 (OH) 2 +20NH 4 NO 3 +6H 2 o

[0051] (2) Dilute the above-mentioned hydroxyapatite slurry with distilled water at a ratio of 5:1 by volume ratio, and add ammonium bicarbonate at a concentration of 0.05 g / ml based on the volume of the diluted hydroxyapatite slurry , mix and stir evenly;

[0052] (3) At a magnetic stirring speed of 500 rev / min, the above-mentioned mixed solution is sprayed with a nozzle diameter of 1mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com