Preparation method of black soybean seed capsule anthocyanin

A black soybean seed coat and anthocyanin technology, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of poor stability and achieve stability, reduce usage, and increase dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Choose "Yueyin Black Soybean No. 1" variety 100Kg, and peel off the black soybean seed coat accounting for 3% of the weight of black soybean as raw material;

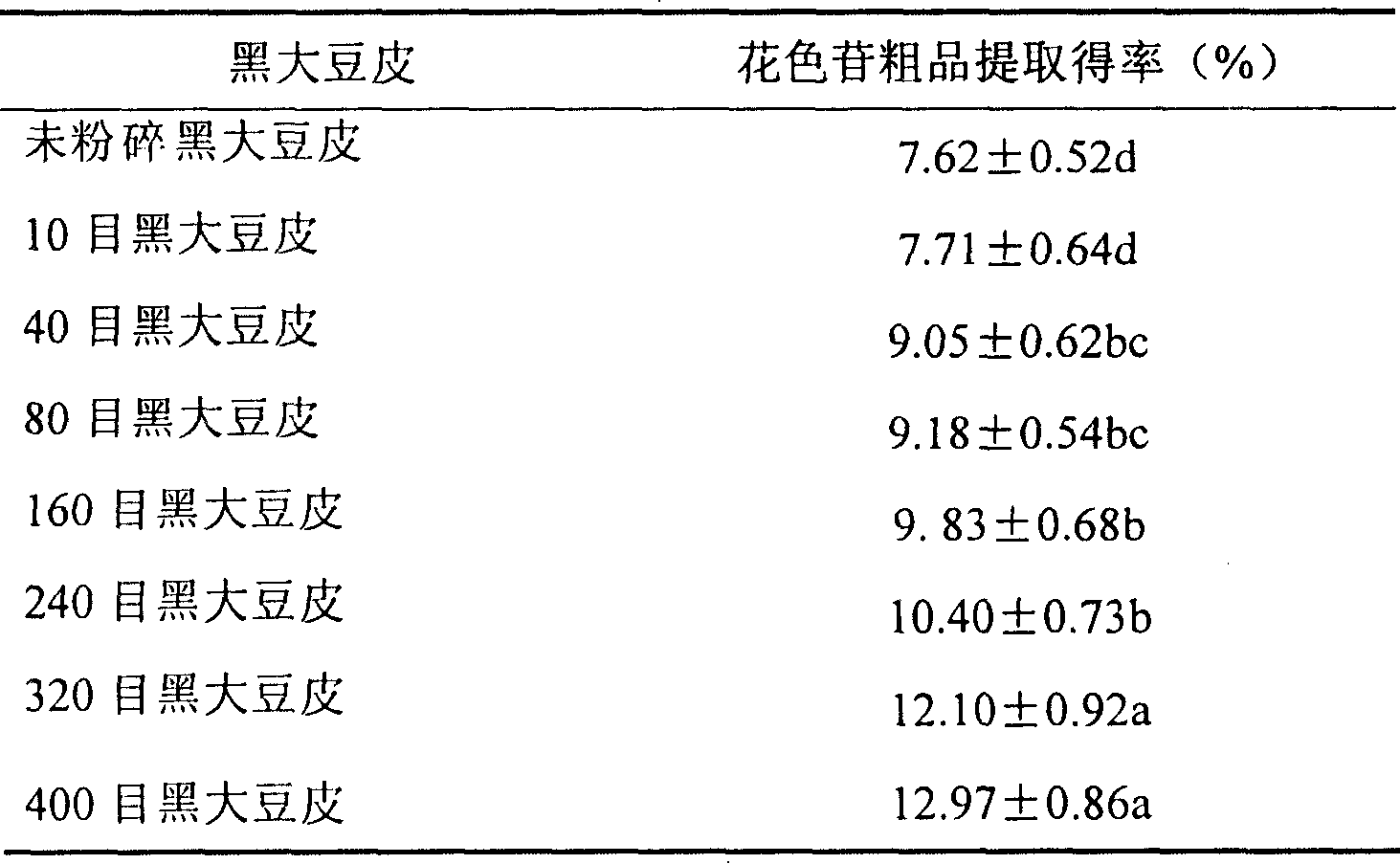

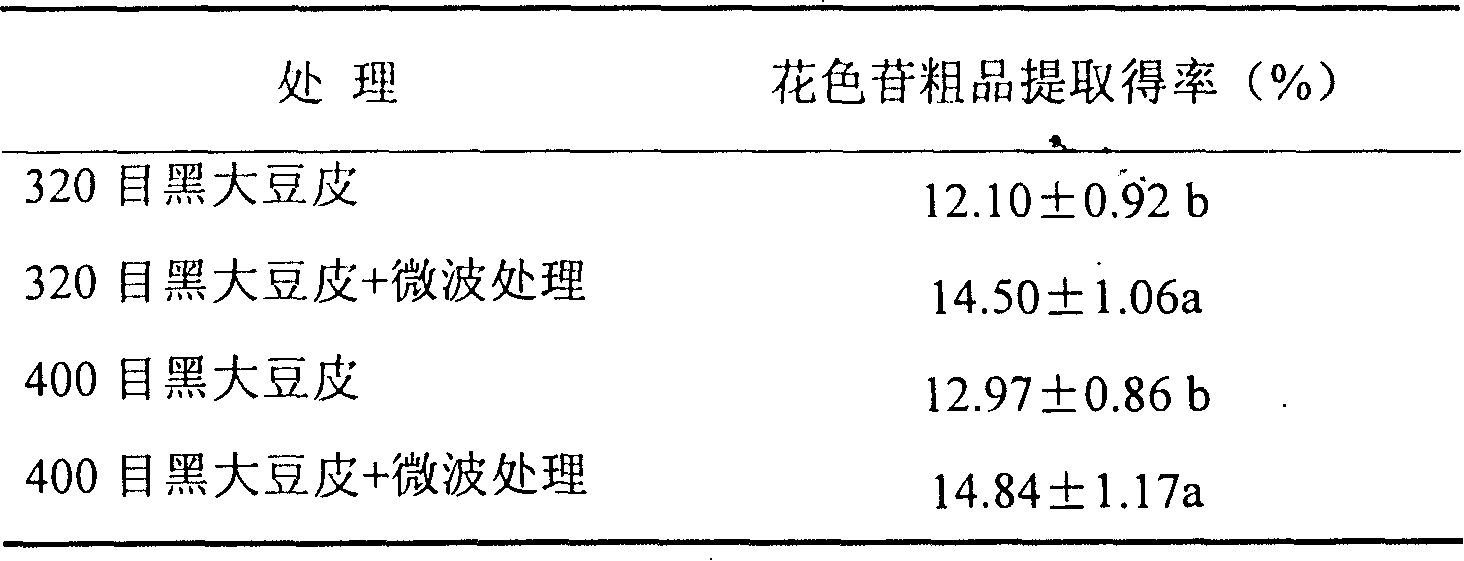

[0042] 2. The black soybean seed coat is pulverized into 320-mesh fine powder with an ultrafine pulverizer; the black soybean seed coat micropowder is processed with a microwave machine, and the cells are broken. Microwave frequency 2450MHz, microwave power 20kw, time 40s;

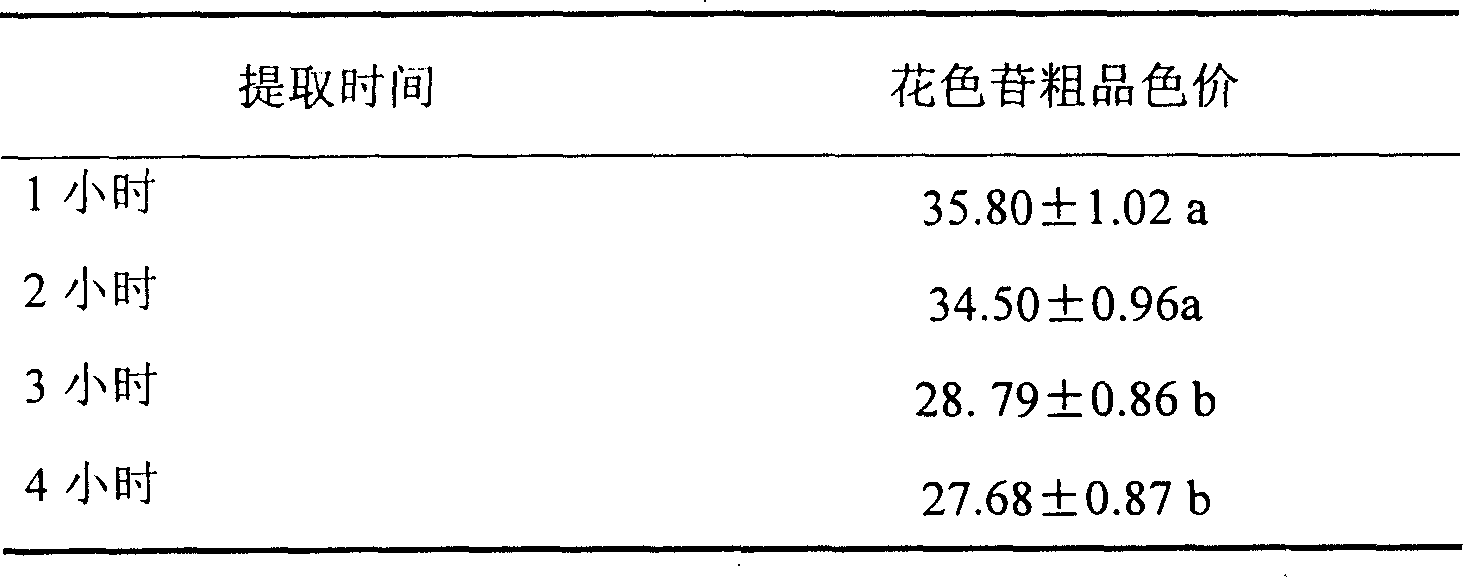

[0043] 3. Using 70% ethanol containing 0.1% vitamin C as a solvent, the above-mentioned black soybean seed coat micropowder is 1:5 at a material-to-liquid ratio, at a temperature of 55° C., for 2 hours for leaching time, and 2 times for leaching times;

[0044] 4. Carry out vacuum concentration to the black soybean anthocyanin extraction solution obtained in step 3, the vacuum degree is 0.09Mpa, the temperature is 50°C, until the solid content concentration of the extraction solution reaches more than 40%;

Embodiment 2

[0048] 1. Choose "Yueyin Black Soybean No. 1" variety 100Kg, and peel off the black soybean seed coat accounting for 4% of the weight of black soybean as raw material;

[0049] 2. The black soybean seed coat is pulverized into a 400-mesh fine powder with a micro pulverizer; the black soybean seed coat micropowder is processed with a microwave machine, and the cells are broken. Microwave frequency 2450MHz, microwave power 12kw, time 60s;

[0050] 3. Using 60% ethanol containing 0.08% vitamin C as a solvent, the above-mentioned black soybean seed coat micropowder is 1:6 according to the material-to-liquid ratio, the temperature is 60°C, the extraction time is 1.5 hours, and the extraction times are 3 times;

[0051]4. Carry out vacuum concentration to the black soybean anthocyanin extraction solution obtained in step 3, the vacuum degree is 0.09Mpa, the temperature is 55 ℃, until the solid content concentration of the extraction solution reaches more than 40%;

[0052] 5. Use p...

Embodiment 3

[0055] 1. Choose "Yueyin Black Soybean No. 1" variety 100Kg, and peel off the black soybean seed coat accounting for 2% of the weight of black soybean as raw material;

[0056] 2. The black soybean seed coat is pulverized into a 400-mesh fine powder with a micro pulverizer; the black soybean seed coat micropowder is processed with a microwave machine, and the cells are broken. Microwave frequency 2450MHz, microwave power 15kw, time 50s;

[0057] 3. Using 80% ethanol containing 0.05% vitamin C as a solvent, the above-mentioned black soybean seed coat micropowder is 1:4 at a material-to-liquid ratio, at a temperature of 70°C, for 1 hour of extraction time, and 3 times of extraction times;

[0058] 4. Carry out vacuum concentration to the black soybean anthocyanin extraction solution obtained in step 3, the vacuum degree is 0.09Mpa, the temperature is 55 ℃, until the solid content concentration of the extraction solution reaches more than 40%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com