Self-regulating type vapor sampling rack for super (super) critical generator set

A generator set and ultra-supercritical technology, which is used in sampling devices, preparation of test samples, etc., can solve the problem of not being able to use ultra-supercritical generator sets for water vapor sampling, etc., and achieves small footprint, material saving, and high heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

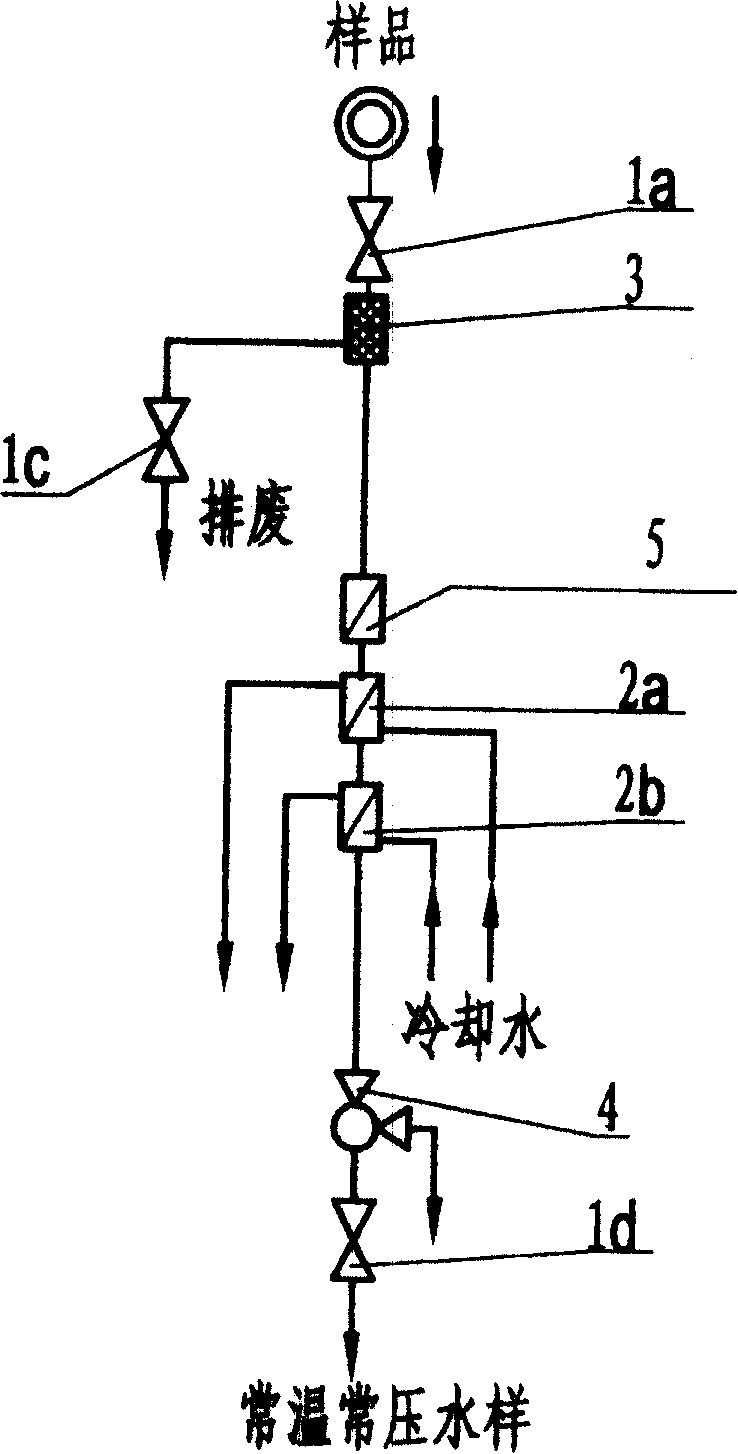

[0034] Embodiment 1: With reference to Fig. 2, the ultra-supercritical generator set self-regulating water vapor sampling rack, the first high temperature and high pressure valve 1a installed on the main road is connected with the water sample inlet of the rod filter 3, the water sample of the rod filter 3 The outlet is connected to the second high temperature and high pressure valve 1b, the waste water outlet of the rod filter 3 is connected to the high temperature and high pressure drain valve 1c, the second high temperature and high pressure valve 1b is connected to the water sample inlet of the air-cooled pre-cooling pressure reducer 5, and the air cooling The water sample outlet of the formula pre-cooling and pressure reducing device 5 is connected with the water sample inlet of the first high-efficiency cooling and pressure reducing device 2a, and the water sample outlet of the first high-efficiency cooling and pressure reducing device 2a is connected with the water sample...

Embodiment 2

[0038] Embodiment 2: refer to Figure 4 , Embodiment 2 The self-adjusting water vapor sampling frame of the ultra-supercritical generating set is basically the same as the structure of Embodiment 1, except that between the water sample outlet of the rod filter 3 and the sample inlet 10 of the air-cooled pre-cooling pressure reducer 5 The second high temperature and high pressure valve 1b is removed.

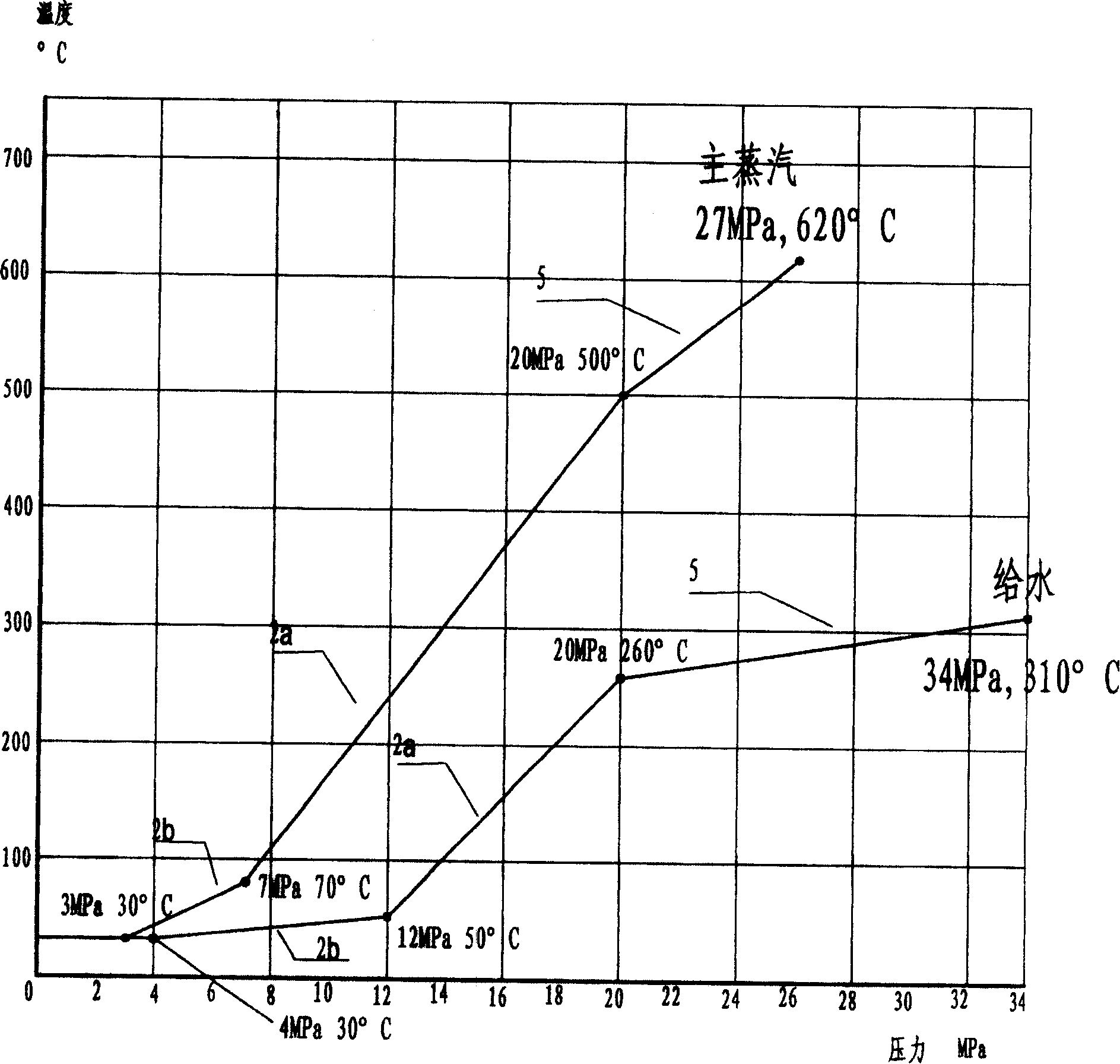

[0039] refer to Figure 5 , the self-adjusting water vapor sampling rack of the ultra-supercritical generating set has a steady-state operating characteristic curve under the stable condition of two representative water sample characteristic parameters. The first curve in the upper part of the figure, firstly, the air-cooled pre-cooling and pressure reducing device 5 uses steam to cool it, and the state changes from 620°C, 27Mpa to 500°C, 20Mpa; then the first high-efficiency cooling and pressure reducing device 2a Use cooling water to make phase change (subcritical steam into l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com