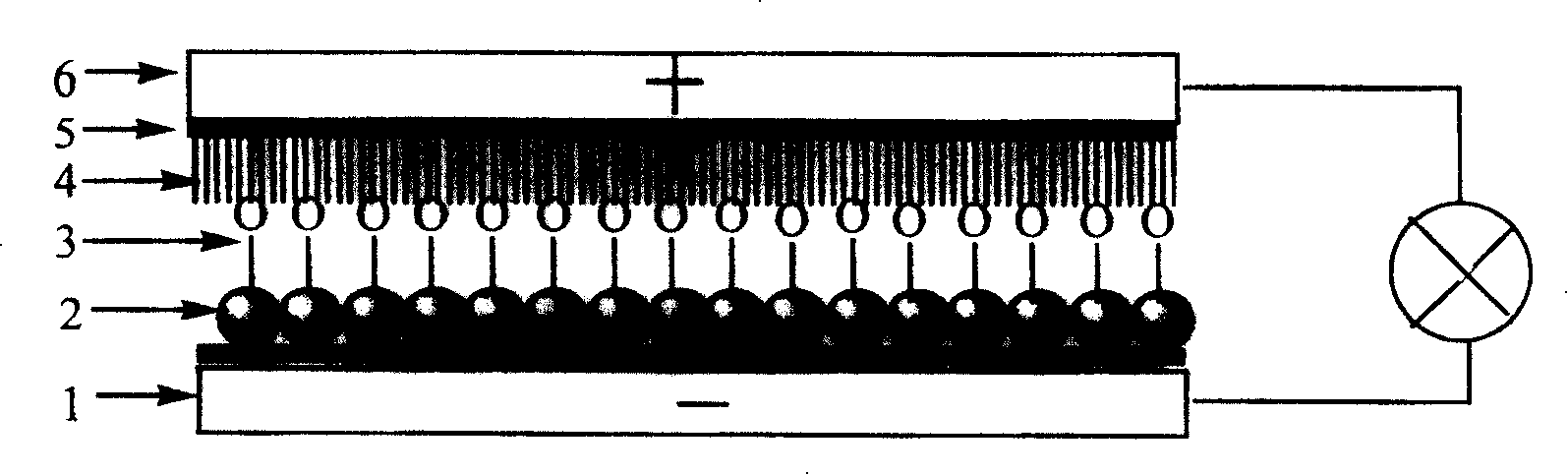

Quasi-solid-state dye sensitized nano crystal salar battery and manufacturing method thereof

A solar cell and dye sensitization technology, which is applied in the field of dye-sensitized nanocrystalline solar cells, can solve the problems of all-solid electrolyte electronic and ion conductivity decline, leakage, liquid electrolyte solvent volatilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

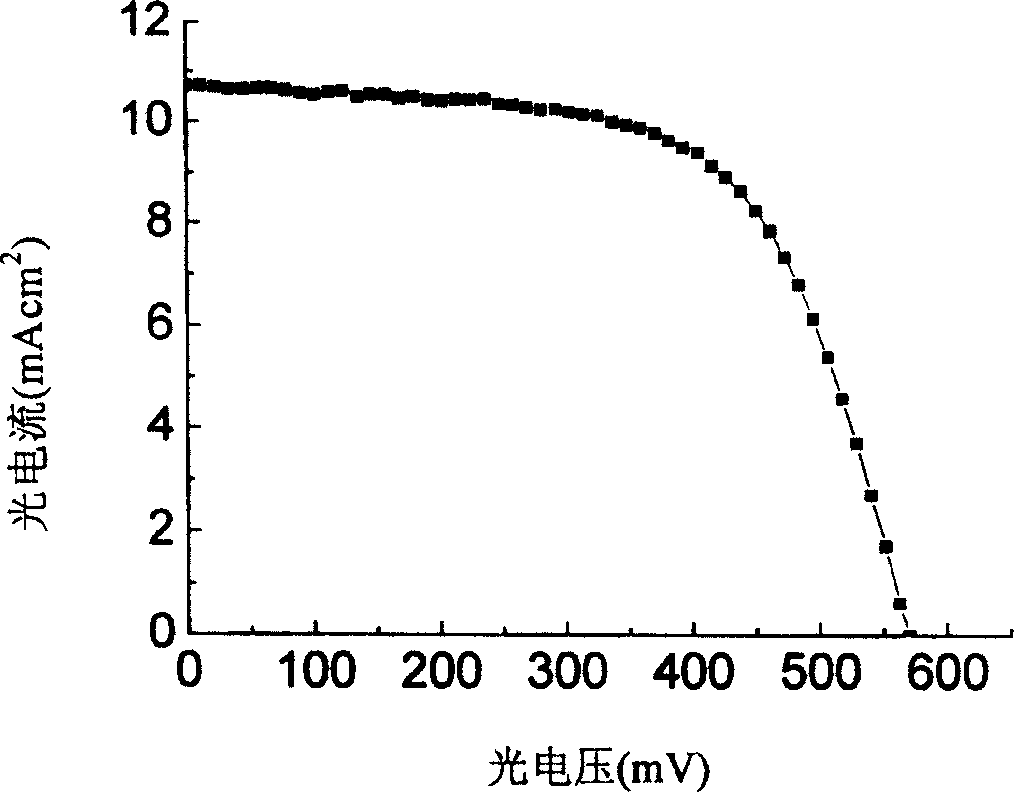

[0025] Embodiment 1: Titanium dioxide nanocrystalline film electrode is placed in 5 * 10 -4 mol / L N 3 Sensitize by soaking in the dye solution for 24 hours. Then drop 0.1mL liquid electrolyte, the composition is 0.1mol / L I 2 , 0.1 mol / L LiI, 0.5 mol / L 4-tert-butylpyridine, 0.6 mol / L 1-methyl-3-propylimidazolium iodide, and then a piece of platinum-coated ITO glass was placed on the dye-sensitized Dye-sensitized solar cells were assembled on the nano-titanium dioxide crystal film and measured. at 80mW / cm 2 Under white light irradiation, the open circuit photovoltage of the battery is 570mV, and the short circuit photocurrent is 10.7mA / cm 2 , The fill factor is 0.62, and the energy conversion efficiency is 4.7%.

Embodiment 2

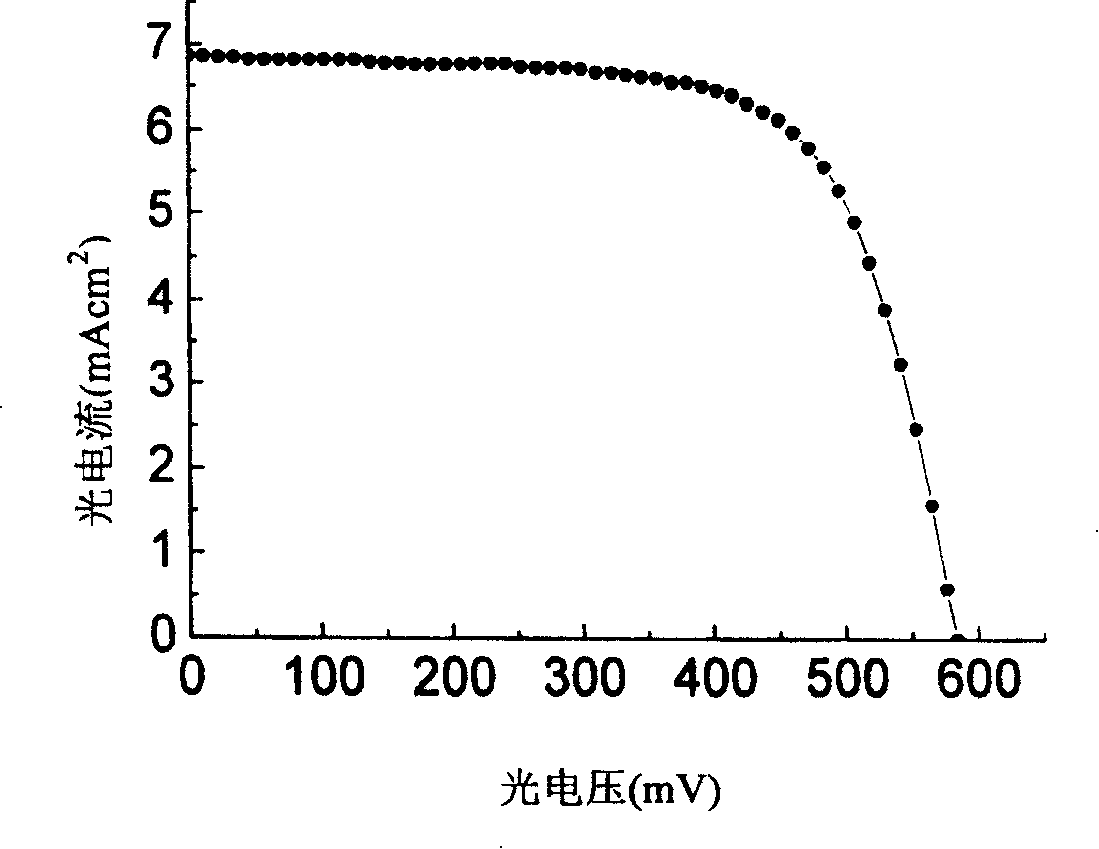

[0026] Embodiment 2: Titanium dioxide nanocrystalline film electrode is placed in 5 * 10 -4 mol / L N 3 Sensitize by soaking in the dye solution for 24 hours. Then drop 0.1mL quasi-solid electrolyte, the composition is 0.1mol / L I 2 , 0.1 mol / L LiI, 0.5 mol / L 4-tert-butylpyridine, 0.6 mol / L 1-methyl-3-propylimidazolium iodide, 0.05% (mass fraction) of mesoporous silica, and then A piece of platinum-coated ITO glass is placed on the dye-sensitized nano-titanium dioxide crystal film, and a dye-sensitized solar cell is assembled and measured. at 80mW / cm 2 Under white light irradiation, the open circuit photovoltage of the battery is 584mV, and the short circuit photocurrent is 6.9mA / cm 2 , The fill factor is 0.68, and the energy conversion efficiency is 3.4%. The photocurrent and photovoltage curves are shown in image 3 shown.

Embodiment 3

[0027] Embodiment 3: Titanium dioxide nanocrystalline film electrode is placed in 5 * 10 -4 mol / L N 3 Sensitize by soaking in the dye solution for 24 hours. Then drop 0.1mL quasi-solid electrolyte, the composition is 0.1mol / L I 2 , 0.1 mol / liter LiI, 0.5 mol / liter 4-tert-butylpyridine, 0.6 mol / liter 1-methyl-3-propylimidazolium salt, 3% (mass fraction) of mesoporous silica, and then a piece of The platinum-coated ITO glass is placed on the dye-sensitized nano-titanium dioxide crystal film, and the dye-sensitized solar cell is assembled and measured. at 80mW / cm 2 Under white light irradiation, the open circuit photovoltage of the battery is 587mV, and the short circuit photocurrent is 6.7mA / cm 2 , The fill factor is 0.68, and the energy conversion efficiency is 3.4%. The photocurrent and photovoltage curves are shown in Figure 4shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com