Perovskite solar cells based on spiro-ometad/PBS composite hole transport layer and its preparation method

A hole transport layer, solar cell technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem of low stability of perovskite solar cells, achieve good photoelectric conversion efficiency and stable performance, process Simple and cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

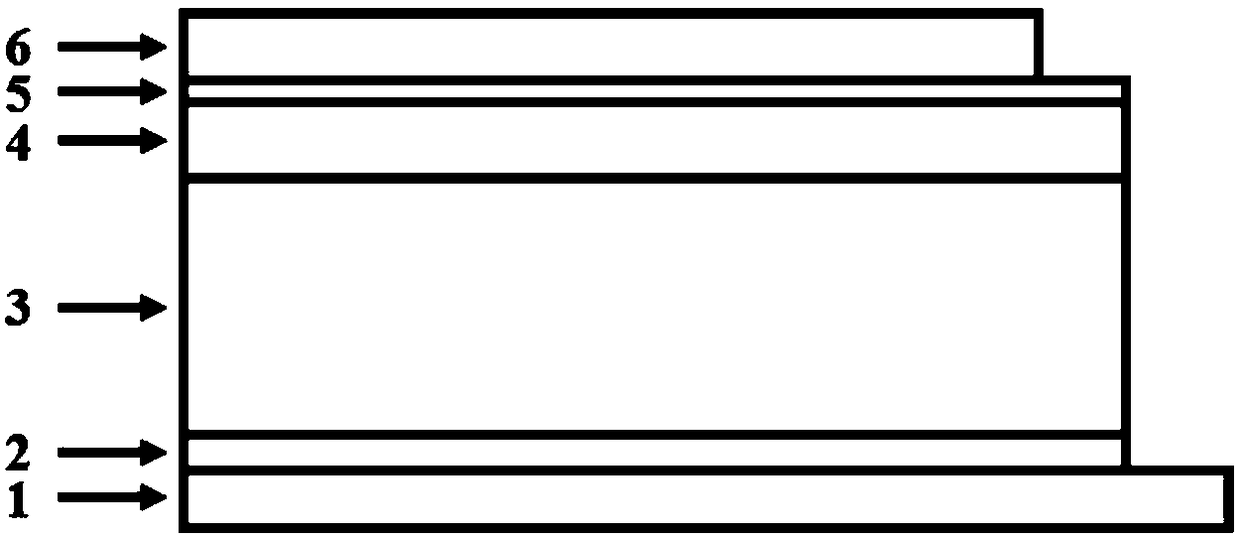

[0052] 1) Cleaning. First, clean and dry the FTO conductive glass. Clean the FTO conductive glass of appropriate size with detergent, and then rinse it with deionized water. Then put it into an ultrasonic cleaner to clean it ultrasonically with acetone, ethanol, and deionized water in sequence, and finally dry it with nitrogen to obtain the FTO conductive glass substrate with a clean surface required for the experiment.

[0053] 2) Preparation of oxide electron transport layer: 0.1mol / L of SnCl 2 2H 2 O ethanol solution was stirred for 30 minutes to obtain SnCl 2 Precursor solution; then SnCl 2 The precursor solution was evenly spin-coated on the cleaned FTO conductive glass with a glue spinner, and annealed at 200 degrees Celsius for 1 hour after the spin-coating was completed to obtain an oxide electron transport layer.

[0054] 3) Perovskite light-absorbing layer (CH 3 NH 3 PB 3 thin film) preparation: pre-synthesized CH 3 NH 3 I and PbI 2 Dissolve in a mixed sol...

Embodiment 2

[0059] 1) Cleaning. With embodiment 1.

[0060] 2) Preparation of oxide electron transport layer: 0.1mol / L of SnCl 2 2H 2 O ethanol solution was stirred for 30 minutes to obtain SnCl 2 Precursor solution; then SnCl 2 The precursor solution was evenly spin-coated on the cleaned FTO conductive glass with a glue spinner, and annealed at 200 degrees Celsius for 1 hour after the spin-coating was completed to obtain an oxide electron transport layer.

[0061] 3) Perovskite light-absorbing layer (CH 3 NH 3 PB 3 thin film) preparation: pre-synthesized CH 3 NH 3 I and PbI2 Dissolve in a mixed solution of dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) at a molar ratio of 1:1 (v / v=4:1), and stir at 60 degrees Celsius for 24 hours to obtain perovskite Precursor solution; then spin-coat the configured perovskite precursor solution evenly on the annealed oxide electron transport layer, first spin-coat at a low speed of 500rpm for 6s, and then spin-coat at a high speed of 400...

Embodiment 3

[0066] 1) Cleaning. With embodiment 1.

[0067] 2) Preparation of oxide electron transport layer: 0.1mol / L of SnCl 2 2H 2 O ethanol solution was stirred for 30 minutes to obtain SnCl 2 Precursor solution; then SnCl 2 The precursor solution was evenly spin-coated on the cleaned FTO conductive glass with a glue spinner, and annealed at 200 degrees Celsius for 1 hour after the spin-coating was completed to obtain an oxide electron transport layer.

[0068] 3) Perovskite light-absorbing layer (CH 3 NH 3 PB 3 thin film) preparation: pre-synthesized CH 3 NH 3 I and PbI 2 Dissolve in a mixed solution of dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) at a molar ratio of 1:1 (v / v=4:1), and stir at 60 degrees Celsius for 24 hours to obtain perovskite Precursor solution; then spin-coat the configured perovskite precursor solution evenly on the annealed oxide electron transport layer, first spin-coat at a low speed of 500rpm for 6s, and then spin-coat at a high speed of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com