Heat-conducting organosilicon, photovoltaic module and packaging method of the photovoltaic module

An encapsulation method and technology for photovoltaic modules, which are applied in the fields of photovoltaic power generation, semiconductor devices, electrical components, etc., can solve problems such as the decline of photovoltaic module photoelectric conversion efficiency and the reduction of photovoltaic module power generation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Component A: 4.8 parts of hydrogen-containing silicone oil, 0.1 part of catalyst, and 0.1 part of inhibitor; Component B: 40 parts of vinyl silicone oil, 5 parts of white carbon black, and 50 parts of boron nitride; 1:1 mixed evenly before use;

Embodiment 2

[0044] Example 2 Component A: 14.8 parts of hydrogen-containing silicone oil, 0.1 part of catalyst, and 0.1 part of inhibitor; Component B: 50 parts of vinyl silicone oil, 15 parts of white carbon black, and 20 parts of boron nitride; 1:1 mixed evenly before use;

Embodiment 3

[0045] Example 3 Component A: 9 parts of hydrogen-containing silicone oil, 0.5 parts of catalyst, and 0.5 parts of inhibitor; Component B: 60 parts of vinyl silicone oil, 5 parts of white carbon black, and 5 parts of boron nitride; The ratio of 3:1 is used after mixing evenly;

[0046] Under the same conditions, the set ratio of component A and component B is blended, and the physical properties of the formed thermal conductive silicone are shown in the following table:

[0047] Example Tensile strength (MPa) Breakdown voltage (KV / mm) Thermal conductivity (W / mK) 1 2.2 >12 6.7 2 3.4 >12 3.1 3 3.7 >12 0.3

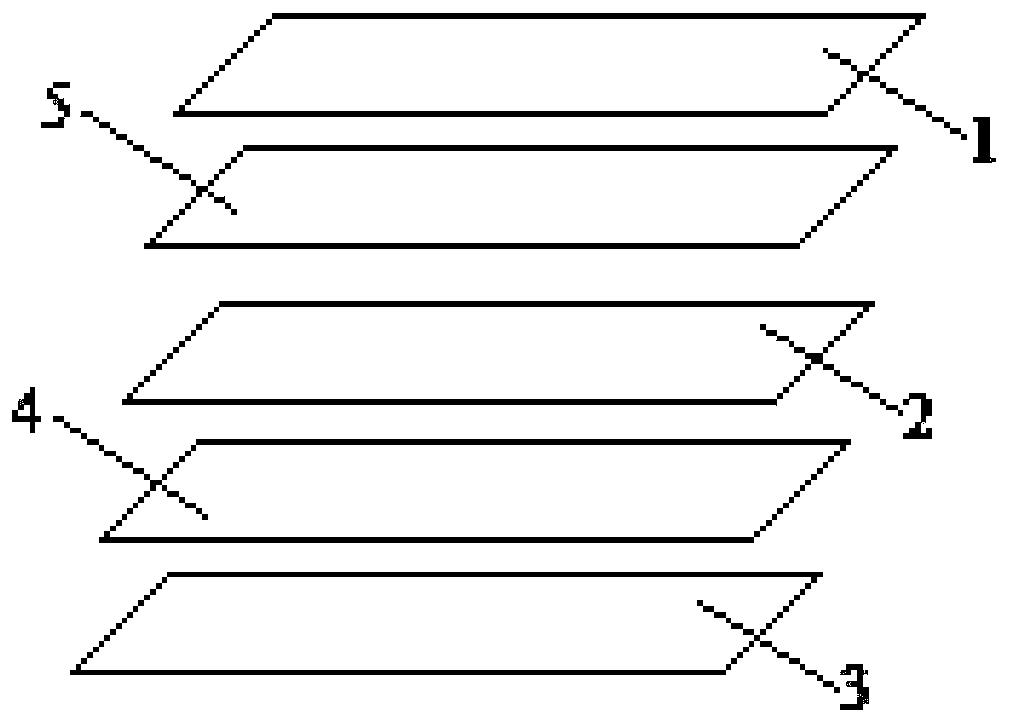

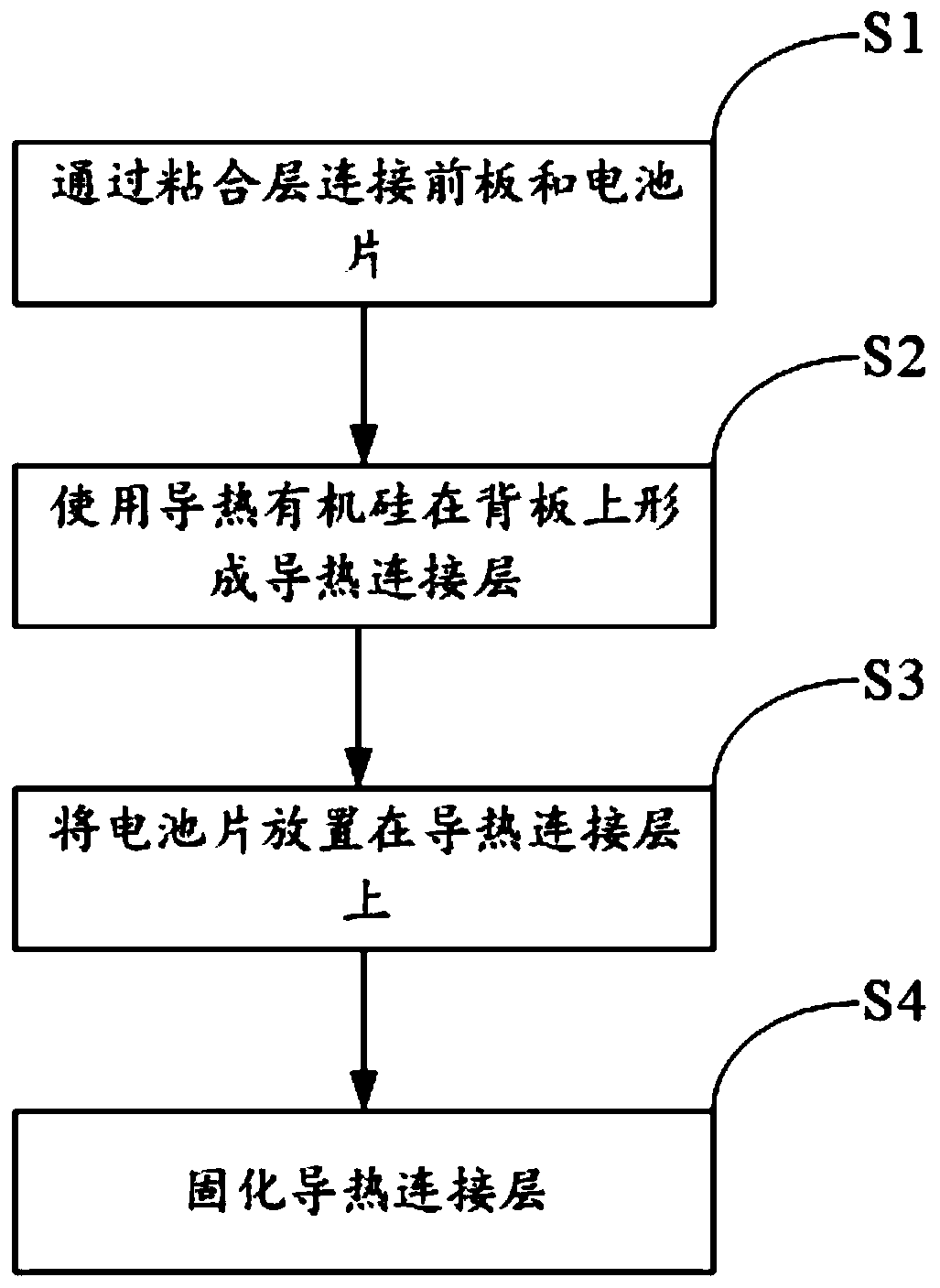

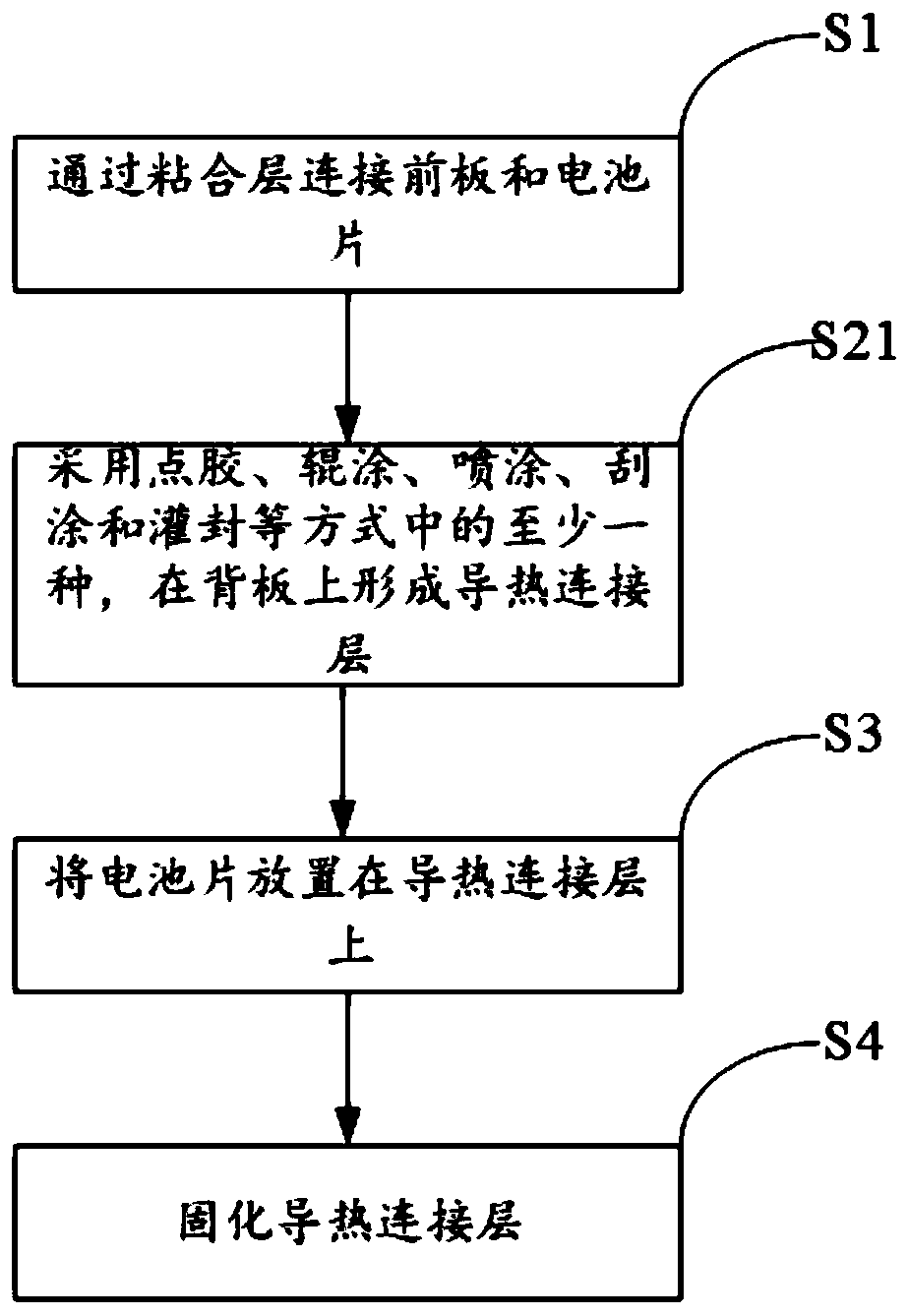

[0048] Based on the thermally conductive silicone provided above, such as figure 1As shown, the present invention also provides a photovoltaic module, which has better heat dissipation performance, and will not reduce the photoelectric conversion rate of the entire photovoltaic module due to heat release and temperature rise of the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com