Light-emitting diode

A technology of light-emitting diodes and light-emitting chips, applied in electrical components, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve problems such as unbalanced energy distribution and non-adjustable divergence angles, and achieve changes in divergence angles, The effect of increasing the divergence angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

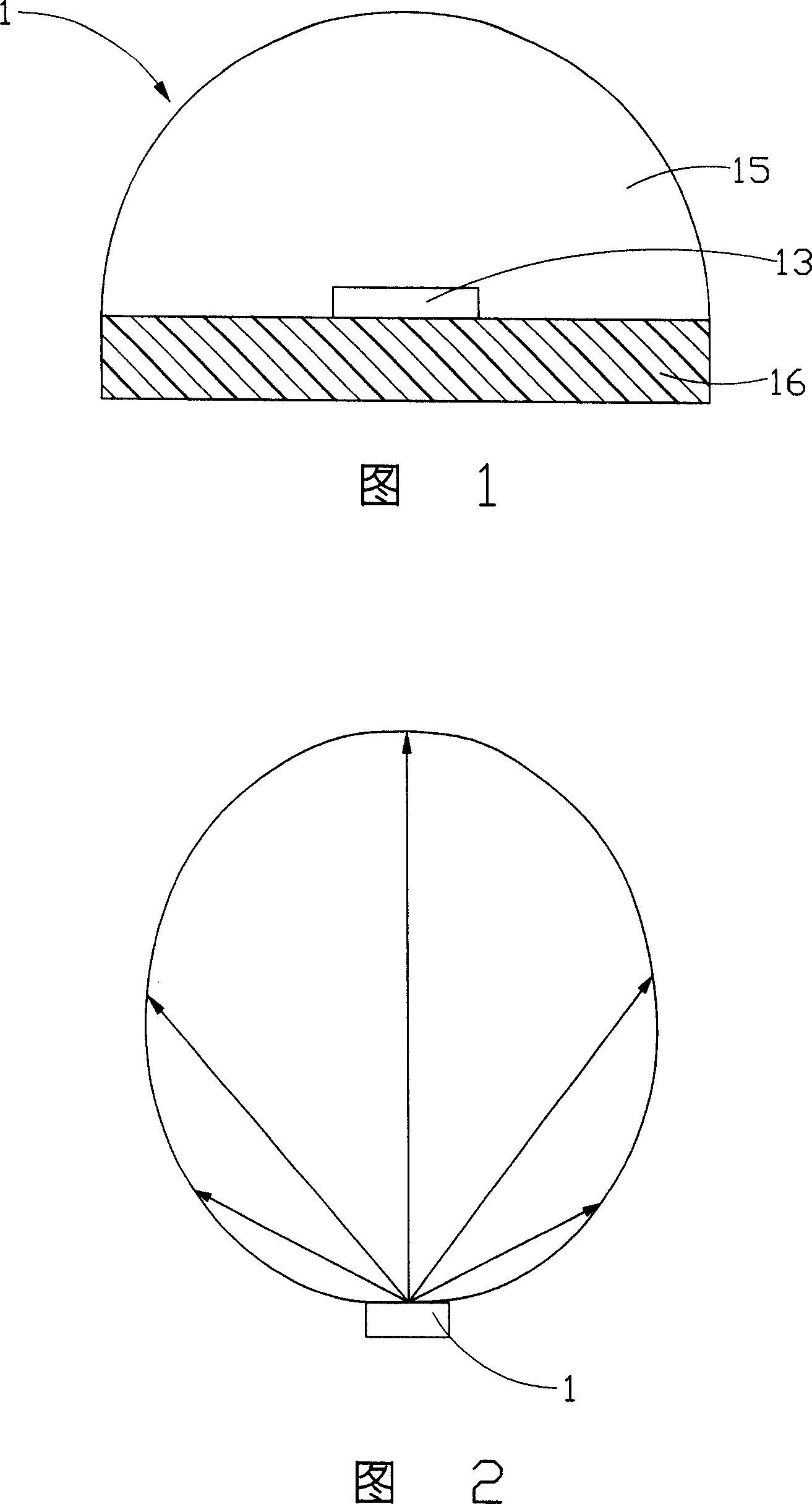

[0012] FIG. 4 is a schematic cross-sectional view of the LED 110 of the present invention. The light emitting diode 110 includes a substrate 111 , a light emitting chip 113 and a packaging structure 115 . The encapsulation structure 115 is used to cover the light-emitting chip 113 and form a light exit surface (not shown), the light exit surface is a curved surface structure, which has the effect of a lens, and the light emitted by the light-emitting chip 113 exits through the light exit surface. A diffraction grating 117 having a plurality of diffraction grating units is continuously arranged on the light exit surface. The diffraction grating 117 is disposed on the light emitting surface, and its distribution area is within the range of the packaging structure 115 irradiated by the light emitting from the light emitting chip 113 . The packaging structure 115 is made of a transparent piezoelectric material, which can be transparent piezoelectric ceramics or polyvinylidene flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com