Nano gamma hydrocarboxyl nickel/high ferrite composite material and preparing method

A technology of nickel oxyhydroxide and ferrate, applied in the direction of nickel oxide/nickel hydroxide, chemical instruments and methods, iron compounds, etc., can solve the problems of high battery production cost, affecting discharge efficiency, poor electrode conductivity, etc., and achieve Improve discharge efficiency and discharge specific capacity, good capacity matching relationship, and improve the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

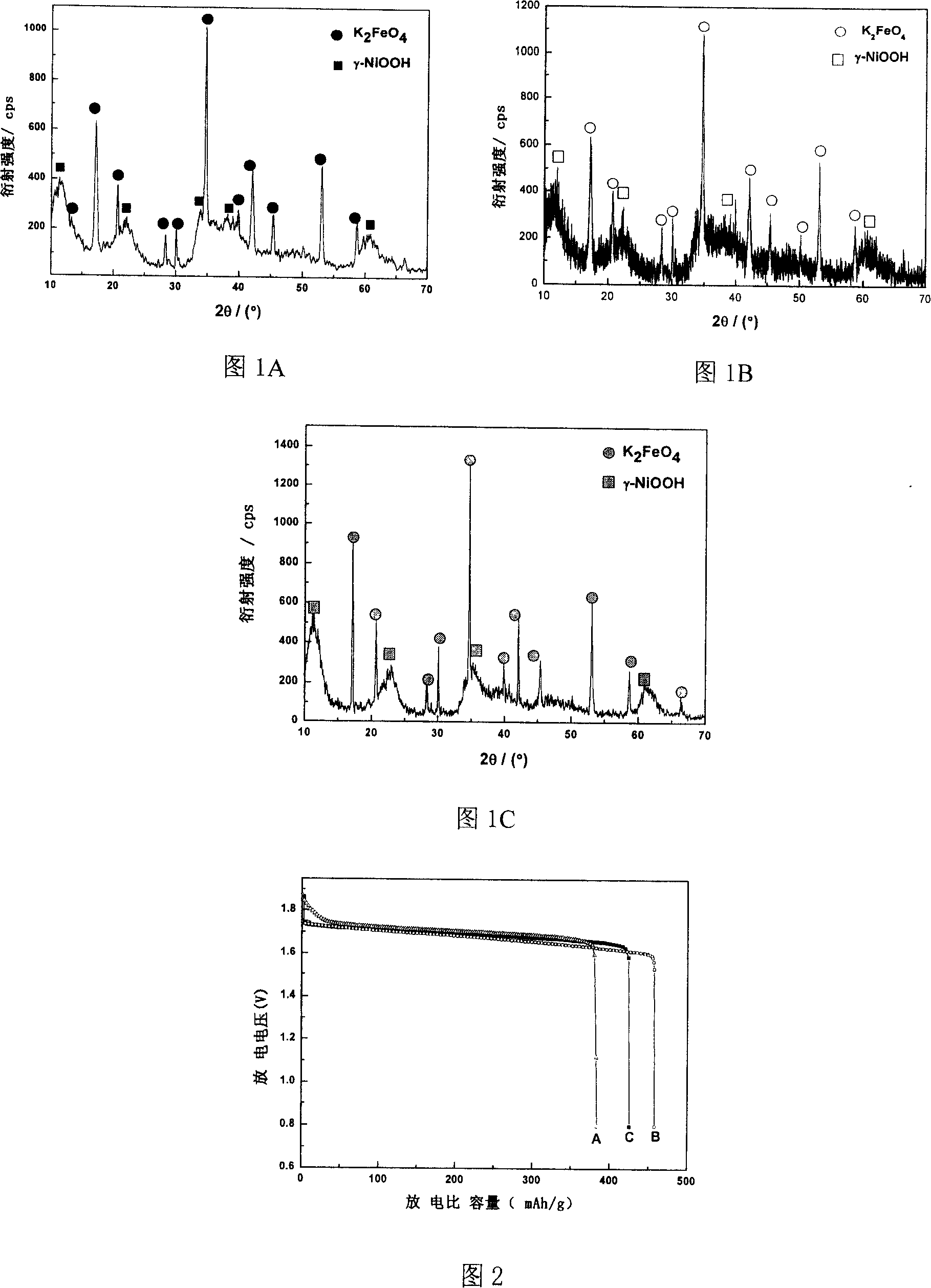

Examples

Embodiment 1

[0027] The first step takes 0.1 mole of nickel nitrate, 0.1 mole of nickel chloride, 0.1 mole of nickel sulfate, adds 0.001 mole of ferric nitrate, 0.001 mole of ferric chloride and 0.001 mole of ferric sulfate (the total amount of moles of iron ions is equivalent to the mole of divalent nickel ions 1%), add 0.001 mole of aluminum nitrate, 0.001 mole of aluminum chloride, 0.0005 mole of aluminum sulfate (the total amount of aluminum ions is equivalent to 1% of the total molar amount of divalent nickel ions), dissolve and prepare nickel / iron The total ion concentration is the reaction solution of 0.1mol / L (the molar concentration unit mol / L of the solution, abbreviated as M, hereinafter the same);

[0028] The second step takes the molar amount (as ClO - Calculation, hereinafter the same) is adding sodium hydroxide solid in the NaClO solution of nickel / iron ion total molar number 300% in the described reaction solution, is mixed with the alkaline oxidizing agent solution that t...

Embodiment 2

[0034] The first step takes 0.5 mole of nickel nitrate, adds 0.025 mole of ferric sulfate (the total molar amount of iron ions is equivalent to 10% of the molar weight of divalent nickel ions), adds 0.0125 mole of cobaltous nitrate, 0.0125 mole of cobaltous sulfate, 0.025 Mole of cobaltous acetate (the total amount of cobaltous ions is equivalent to 10% of the total molar amount of divalent nickel ions) and 0.025 moles of aluminum nitrate (the amount of aluminum ions is equivalent to 5% of the molar amount of nickel ions), dissolved in distilled water to prepare The reaction solution whose total concentration of nickel / iron metal ions is 0.5M;

[0035] The second step takes the molar amount (as ClO - Calculation) is that potassium hydroxide solid is added in the KClO solution of nickel / iron ion total molar number 400% in the described reaction solution, is mixed with the alkaline oxidizing agent solution that potassium hydroxide concentration is 6M;

[0036] In the third step...

Embodiment 3

[0041] The first step takes 1.0 mole of nickel nitrate, adds 0.15 mole of ferric chloride (the total molar amount of iron ions is equivalent to 15% of the molar weight of divalent nickel ions), adds 0.05 mole of manganese nitrate, 0.025 mole of manganese chloride, 0.025 mole Mole of manganese sulfate (the total amount of manganese ions is equivalent to 10% of the total molar weight of divalent nickel ions) and 0.1 mole of aluminum nitrate (the amount of aluminum ions is equivalent to 10% of the molar weight of nickel ions), dissolved in distilled water to prepare nickel / A reaction solution with a total concentration of iron metal ions of 1.0M;

[0042] The second step takes the molar amount (as ClO - Calculation) is that potassium hydroxide solid is added in the KClO solution of nickel / iron ion total molar number 500% in the described reaction solution, is mixed with the alkaline oxidizing agent solution that potassium hydroxide concentration is 6M;

[0043] In the third ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com