Adhesive for resin roll assembly and resin roll

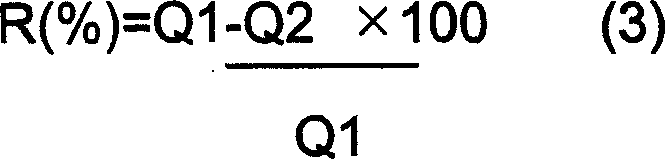

An adhesive and roller technology, which is used in the field of adhesives and resin rollers for assembling resin rollers, can solve the problems of splitting, difficult to inject into the gap of several millimeters, and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0091] In a 2L glass container, put 80 parts of Ebicot epoxy resin 828 (manufactured by Yukaxiu Luo Yubao Kexi (シュルユポキシ) company; bisphenol A type epoxy resin, 20 parts of GOT (Nippon Kayaku Co., Ltd.; glycidyl-O-toluidine), when stirred at 80°C for 30 minutes, a light yellow transparent liquid with a viscosity of 3000mPa.s (25°C) was obtained. This was used as the main ingredient (1).

manufacture example 2

[0093] Except that 80 parts of Epicott epoxy resin 828, 10 parts of GOT, and 10 parts of GAN (manufactured by Nippon Kayaku Co., Ltd.; N, N-diglycidylaniline) were loaded, the viscosity was 3300 mPa as in Production Example 1. .s (25°C) light yellow transparent liquid. Use it as the main ingredient (2).

manufacture example 3

[0095] Except that 70 parts of Epicott epoxy resin 828, 20 parts of GOT, and 10 parts of ELM-100 (manufactured by Sumitomo Chemical Co., Ltd.; triglycidyl P-alkylaminophenol) were loaded, the viscosity was obtained as in Example 1. It is a light yellow transparent liquid at 2500mPa.s (25°C). Use it as the main ingredient (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com