Chemical modification technique for microfiltering separation film of polyvinylidene fluoride

A polyvinylidene fluoride, chemical modification technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology and other directions, to achieve the effects of simple operation, improved efficiency, and improved hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

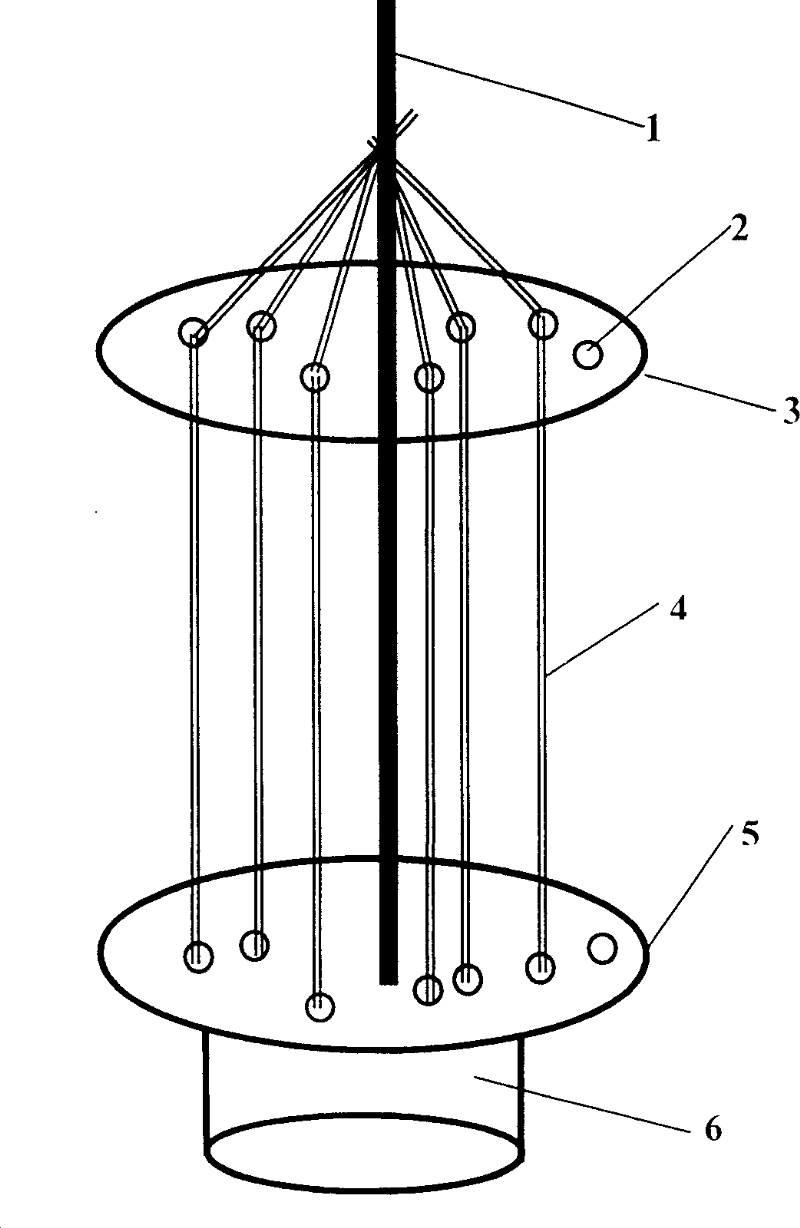

Image

Examples

Embodiment Construction

[0024] The specific chemical modification methods of polyvinylidene fluoride polyvinylidene fluoride hollow fiber micro-membranes and flat-plate membranes are:

[0025] 1) Preparation of polyvinylidene fluoride hollow fiber membrane and flat membrane:

[0026] Weigh a certain amount of porogen polyvinylpyrrolidone, improver polyethylene glycol and lithium chloride first dissolve with a small amount of N,N-dimethylacetamide solvent, then add to N,N-dimethylacetamide solvent Stir in;

[0027] Then weigh the polyvinylidene fluoride powder and add it into the mixed liquid, continue to stir, and heat in a water bath at the same time, and the temperature of the water bath is 85°C to 90°C. After each component is fully dissolved, control the temperature of the water bath to 40°C to 50°C, and let the casting solution stand for about 12 hours for defoaming;

[0028] The mass percentages of polyvinylidene fluoride, polyvinylpyrrolidone, polyethylene glycol, lithium chloride, and N, N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com