Method and device for grinding a rotationally symmetric machine part

A machine component, rotationally symmetric technology, applied in the direction of grinding machine parts, machine tools designed for grinding the rotating surface of workpieces, grinding frames, etc., can solve the problems of short life, uneven cooling of grinding positions, etc. Uniform and cooling zone, the grinding speed remains uniform, the effect of a narrow cooling zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

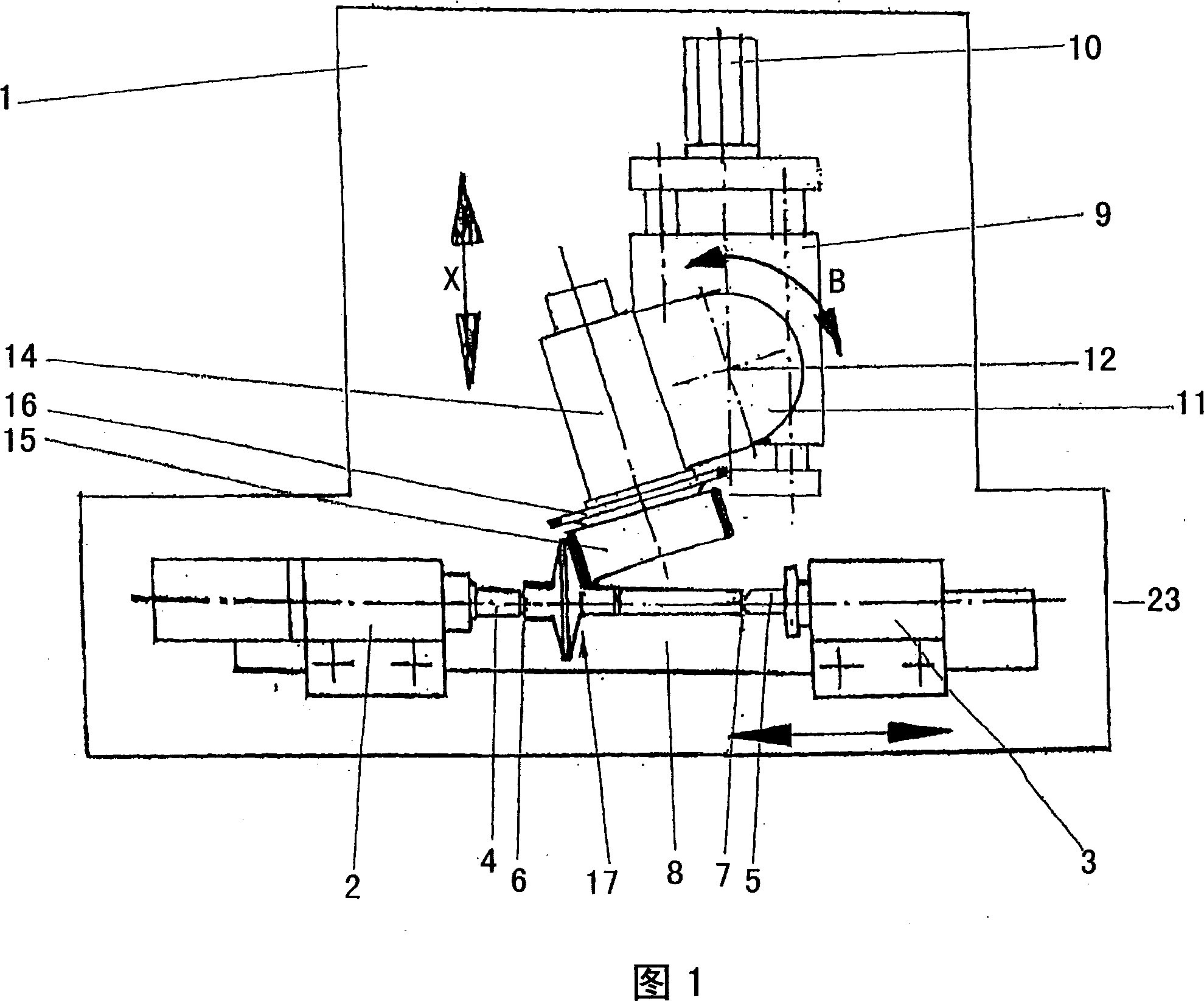

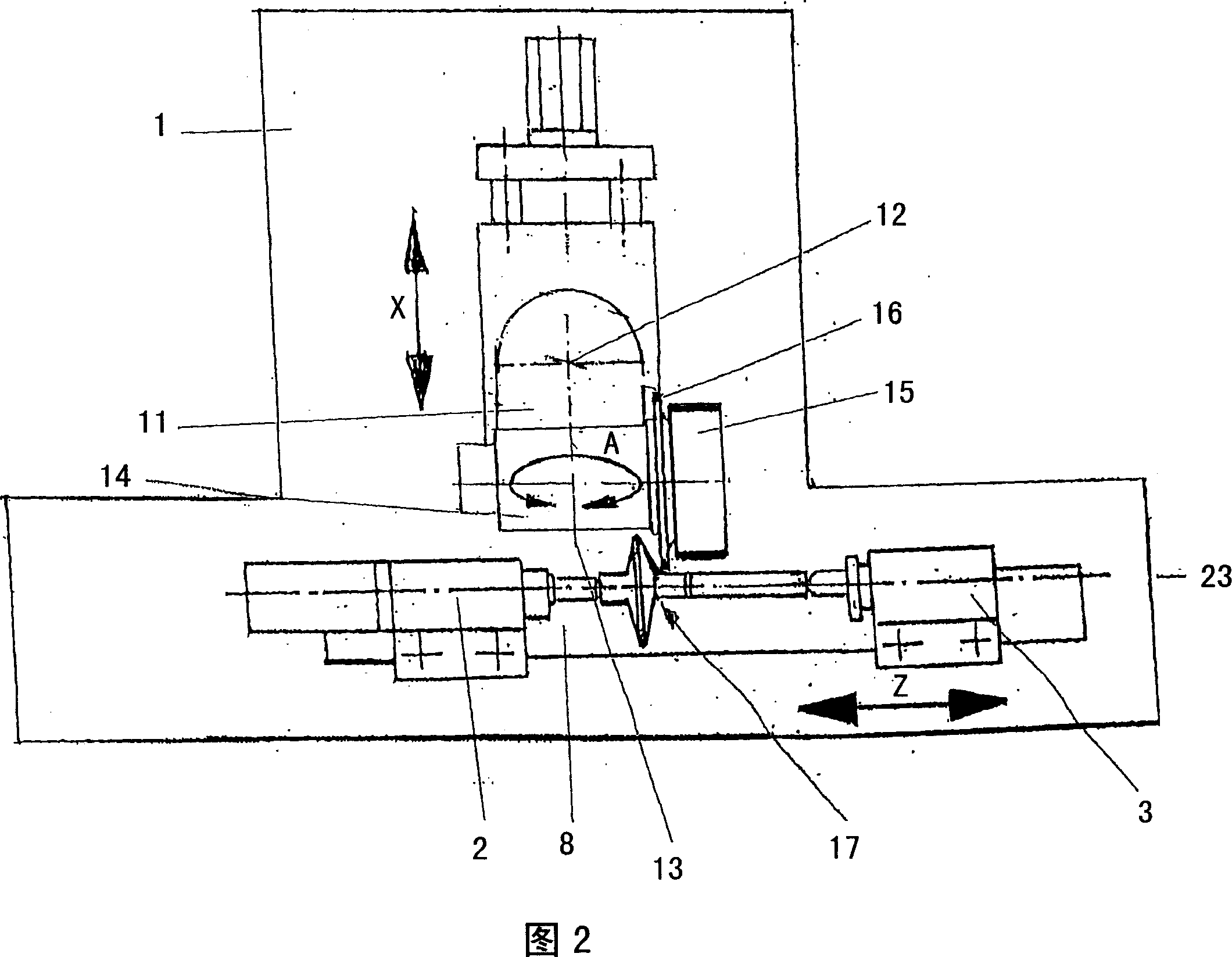

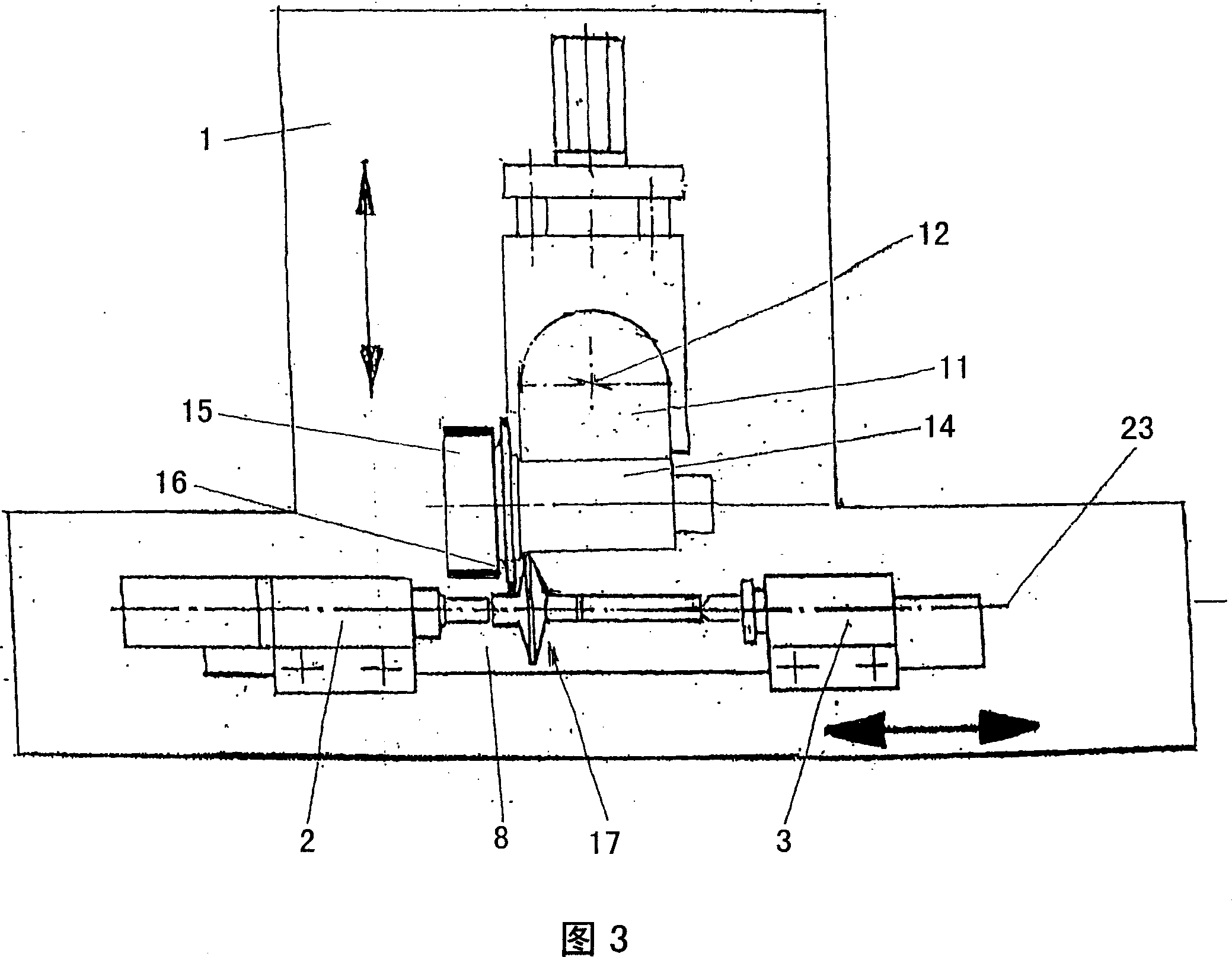

[0057] FIG. 1 shows the device according to the invention for grinding, in particular for carrying out the method according to the invention. The device shown in FIG. 1 consists of a bed 1 on which a workpiece spindle headstock 2 and a tailstock 3 are arranged. The workpiece spindle headstock 2 and tailstock 3 have conventional center sleeves (not shown in the figures) with centers 4, 5 having centers 6 and 7 on the shaft between which machine parts 17 are clamped. between. In the exemplary embodiment shown, the workpiece spindle headstock 2 and the tailstock 3 are arranged on a grinding machine table 8 which is displaceable in the longitudinal direction of the machine part 17 . After clamping, the machine part 17 , the workpiece headstock 2 and the tailstock 3 have a common longitudinal axis 23 which is the reference line on which the other parts are arranged.

[0058] FIG. 1 also schematically shows a grinding wheel spindle saddle 9 which can be advanced in a direction per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com