Isocyanates are indispensable chemical intermediates, best known for their role in producing polyurethanes—materials that span from foams and coatings to elastomers and biomedical devices. Their reactive -N=C=O functional group enables broad versatility in polymer synthesis, but also raises regulatory and safety concerns. As industries seek more sustainable and high-performance solutions, isocyanate innovation is entering a new chapter.

This blog dissects the molecular design, performance characteristics, industrial relevance, and future direction of isocyanate-based technologies, offering a deep dive into their role in next-gen manufacturing, sustainable materials, and advanced chemistry through PatSnap’s Eureka AI Agent.

Chemical Structure & Composition

Isocyanates are organic compounds that contain one or more isocyanate groups (-N=C=O). They are broadly classified into:

- Aromatic Isocyanates (e.g., TDI – Toluene Diisocyanate, MDI – Methylene Diphenyl Diisocyanate)

- Aliphatic Isocyanates (e.g., HDI – Hexamethylene Diisocyanate, IPDI – Isophorone Diisocyanate)

Each category brings unique reactivity and UV stability characteristics. Aromatics offer higher reactivity (ideal for foams), while aliphatics excel in outdoor durability (used in coatings and elastomers).

Key Performance Characteristics

- High Reactivity: Forms strong urea/urethane bonds with alcohols and amines.

- Customizability: Enables tailored mechanical, thermal, and chemical resistance.

- Curing Flexibility: Compatible with one- and two-component systems.

- Adhesion: Offers superior bonding across metals, plastics, and composites.

- Barrier Properties: Excellent moisture, gas, and chemical resistance.

Comparative Advantages & Limitations

Advantages

- Exceptional Chemical Reactivity and Bonding Strength

Isocyanates form robust covalent bonds with hydroxyl and amine groups, enabling the synthesis of high-performance polyurethanes, polyureas, and related networks with superior mechanical strength, abrasion resistance, and chemical durability. This reactivity supports both ambient and elevated temperature curing across diverse formulations. - Tailorable Reactivity Profile Across Molecular Architectures

By varying the backbone structure (aromatic vs. aliphatic) and functional group count (monomeric, polymeric, or trimerized forms), manufacturers can precisely control curing kinetics, final polymer crosslink density, and material flexibility—essential for fine-tuning foams, coatings, adhesives, and elastomers. - Mature Supply Chains and Commercial Accessibility

Industrial-scale production of key diisocyanates (e.g., TDI, MDI, HDI, IPDI) ensures global availability at competitive pricing. This mature ecosystem supports economies of scale, predictable logistics, and compatibility with legacy processing infrastructure. - Cross-Industry Versatility

Isocyanate systems are compatible with a broad range of polymer matrices and substrates, enabling deployment in diverse sectors such as automotive interiors, aerospace coatings, biomedical devices, construction insulation, electronics encapsulation, and marine protection.

Limitations

- Occupational Health and Safety Hazards

Many isocyanates (especially monomeric TDI and MDI) are potent respiratory sensitizers and dermal irritants. Even low-level chronic exposure can lead to occupational asthma and long-term pulmonary damage. Stringent personal protective equipment (PPE), real-time air monitoring, and exhaust ventilation are essential in both lab and industrial settings. - Stringent Global Regulatory Oversight

Regulatory frameworks such as the European Union’s REACH and the U.S. OSHA Hazard Communication Standard impose strict exposure limits, labeling requirements, and registration duties. The push for “monomer-free” or “ultra-low monomer” formulations is reshaping procurement and formulation strategies, particularly in consumer-facing products. - Volatile Organic Compound (VOC) Emissions and Environmental Burden

Solvent-based isocyanate systems contribute to atmospheric VOCs and photochemical smog. Additionally, the thermal degradation of polyurethane products can release hazardous compounds, raising life cycle and end-of-life disposal concerns. Waterborne and high-solids isocyanate formulations mitigate this but often involve trade-offs in performance or curing conditions. - Difficulties in Recycling and Circularity

Thermoset polyurethanes and polyureas derived from isocyanates are chemically crosslinked, making them inherently difficult to depolymerize or mechanically recycle. Although chemical recycling via glycolysis or aminolysis is under development, these methods remain energy-intensive and not yet economically scalable.

Application Domains

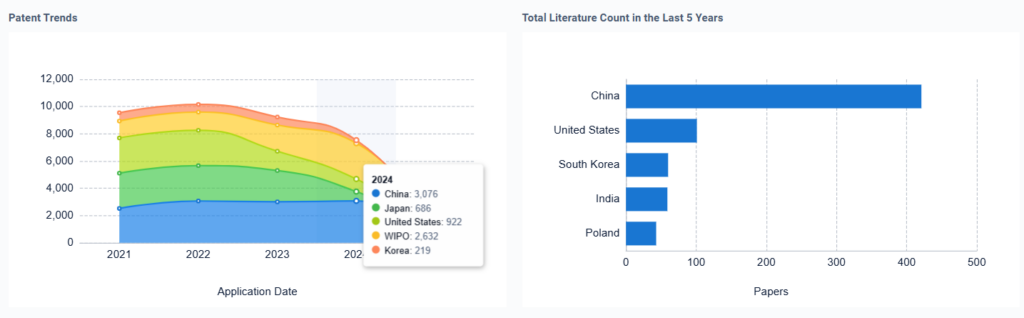

Market and Economic Trends

Global demand for polyurethane materials, coatings, and elastomers has driven significant attention toward the isocyanate market. However, supply chain volatility, geopolitical uncertainties, and sustainability pressure demand deeper market foresight and entry optimization strategies. Isocyanate-based systems remain a cost-efficient and versatile solution for multiple sectors, and understanding market dynamics enables manufacturers and R&D teams to maintain competitiveness.

Research Frontlines:

Efforts focus on growth projections in Asia-Pacific, long-term demand trends from automotive and construction, pricing mechanisms, and global leader strategies.

Related Reports:

- Isocyanate Market Innovations Driving Sustainability

- Market Forecast: Isocyanate Demand and Supply Dynamics

- Isocyanate Market Dynamics in Emerging Economies

- Key Drivers for Isocyanate Market Expansion

- How to Strategize Isocyanate Market Entry Points?

- Isocyanate Trends in Emerging Industrial Sectors

- Isocyanate Market Dynamics Amid Global Challenges

- Isocyanate Market Size and Growth Projections Explored

- Isocyanate Market Leaders Pushing Boundaries

Sustainability and Environmental Impact

As industries accelerate their decarbonization efforts, the spotlight has turned toward greener isocyanate technologies. Traditional formulations pose toxicity and emission concerns, making sustainability transformation a central theme. Bio-based precursors, low-emission reactions, and circular processing pathways allow isocyanates to align better with environmental targets.

Research Frontlines:

Development includes green catalysis, end-of-life recycling schemes, low-VOC polyurethane systems, and collaborative sustainability roadmaps across chemical sectors.

Related Reports:

- Isocyanate Industry Response to Green Chemistry Movements

- Isocyanate Developments in Environmental Impact Reduction

- Exploring Isocyanate Trends in Sustainable Manufacturing

- How to Implement Isocyanate Sustainability Initiatives?

- How Isocyanates Align with Circular Economy Objectives?

- Isocyanate Transformations: Powering Low-Emission Solutions

- Impact of Isocyanates on Global Environmental Goals

- How Isocyanates Contribute to Sustainable Growth Models?

- Isocyanate Research: Progress in Green Chemistry Applications

- Unlocking Potential via Isocyanate Collaborative Endeavors

Safety and Regulatory Compliance

Handling isocyanates involves significant occupational and environmental safety risks, prompting global regulatory revisions. From REACH and TSCA compliance to local worker protection laws, companies face growing pressure to implement robust safety protocols. Process safety, emissions control, and regulatory navigation have become essential components of isocyanate operations.

Research Frontlines:

Innovation spans safer packaging, automated exposure monitoring, enhanced workplace training, and lifecycle risk assessments integrated with digital platforms.

Related Reports:

- Mapping Isocyanate Regulatory Changes: Industry Impacts

- Strategies for Isocyanate Risk Mitigation in Manufacturing

- How to Navigate Isocyanate Regulatory Compliance Challenges?

- Industry Best Practices for Isocyanate Waste Management

- How to Enhance Isocyanate Storage and Handling Safety?

- Examining Isocyanate Global Supply Chain Challenges

- Isocyanate Safety Protocols in Workplace Environments

- Examining Opportunities Within Isocyanate Industry Revolutions

- Strategies for Isocyanate Regulatory Compliance Excellence

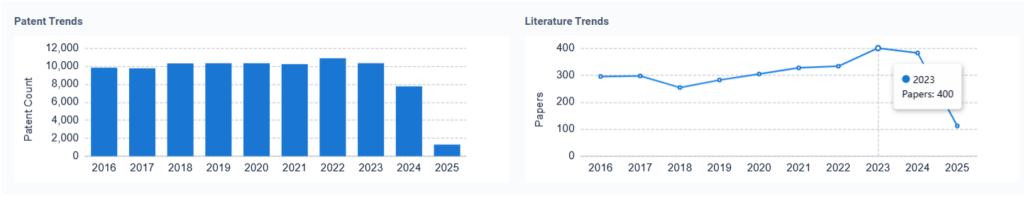

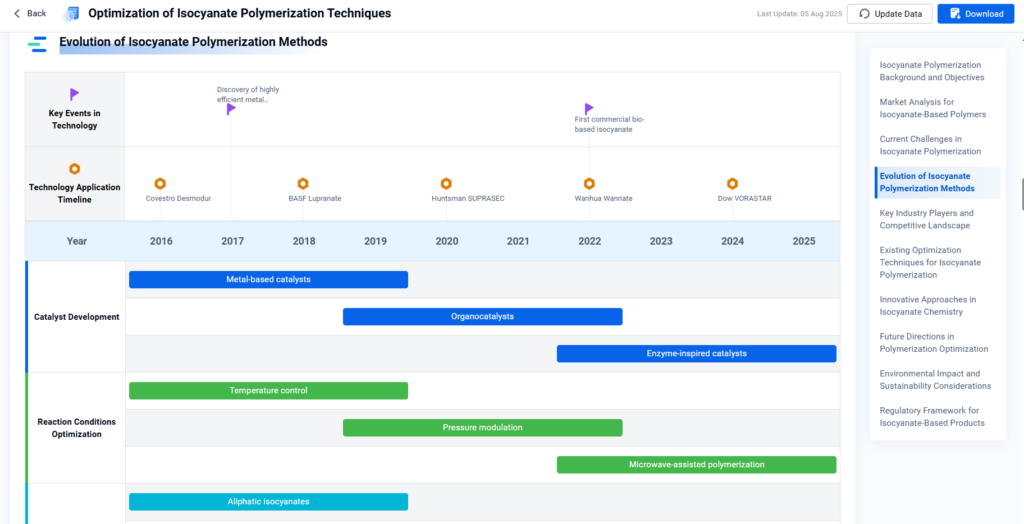

Technological Innovations and Manufacturing Processes

Industrial players seek to enhance isocyanate chemistry through process intensification, greener syntheses, and polymerization control. Catalysis and precision reaction control remain at the forefront, enabling better energy efficiency, higher yields, and broader material functionalities.

Research Frontlines:

Current research focuses on continuous flow synthesis, microwave-assisted catalysis, digital twin modeling of isocyanate processes, and scalable production of bio-based variants.

Related Reports:

- Future Trends in Isocyanate Manufacturing Processes

- Isocyanate Chemistry: Evolution of Industrial Practices

- Cutting-Edge Catalysis Methods for Isocyanate Synthesis

- Advances in Isocyanate-Free Alternatives for Industry Use

- How to Optimize Isocyanate Polymerization Techniques?

- How to Effectively Scale Isocyanate Production Practices?

- Advances in Isocyanate Reaction Control Techniques

- Innovations in Isocyanate Processing: Minimizing Risks

- Breaking Down Isocyanate Catalysis for Improved Efficiency

- Mapping the Growth of Isocyanate Synthesis Technologies

- Isocyanate Industry Developments in Renewable Energy

Applications and Performance Enhancements

Isocyanates are integral to high-performance coatings, adhesives, elastomers, and medical-grade polymers. They provide superior chemical resistance, structural strength, and thermal stability. As new use cases in electronics, lightweighting, and biomedical emerge, performance-tuned isocyanate systems offer key competitive advantages.

Research Frontlines:

Applications are expanding into advanced semiconductors, implantable devices, wearable adhesives, and next-gen automotive materials with optimized heat resistance.

Related Reports:

- Isocyanate Applications in Automotive Manufacturing

- How Isocyanates Innovate in Flexible Packaging Solutions?

- How to Apply Isocyanates in Coating Formulations?

- Isocyanates in Electronics: Enhancing Performance Metrics

- How Isocyanates Improve Adhesive and Sealant Performance?

- Isocyanate Use in Medical Devices: Recent Innovations

- How Isocyanates Enable Superior Structural Integrity?

- Isocyanate Integration: The Backbone of Industrial Advancements

- Isocyanate Applications for Enhanced Heat Resistance

Alternatives and Future Directions

As environmental regulations tighten and green chemistry gains momentum, the search for viable alternatives to traditional isocyanates has intensified. Researchers and industry leaders are now turning toward bio-based inputs, non-isocyanate pathways, and advanced recycling techniques—each offering a possible roadmap to reduce health and ecological risks.

But how do these alternatives compare in terms of cost, performance, and scalability?

What’s the trade-off between eliminating toxic precursors and maintaining product functionality?

And which isocyanate-free strategies are actually viable for commercial deployment?

Try PatSnap Eureka AI Agent to uncover answers!

Emerging Trends & Research Directions

- Next-Gen Bio-Isocyanates: Sourcing raw materials from renewable oils and lignin derivatives.

- Non-Isocyanate Polyurethanes (NIPUs): Using cyclic carbonates and amines as safer alternatives.

- Smart Isocyanate Systems: Incorporating stimuli-responsive properties (temperature, pH) in coatings and biomedical polymers.

- AI-Driven Formulation: Predicting reaction pathways and mechanical properties through machine learning.

Conclusion

Isocyanates remain at the heart of modern materials science, powering everything from foam mattresses to aerospace coatings. Yet, their future hinges on addressing toxicity, sustainability, and regulatory challenges. Whether through safer formulations or bio-derived alternatives, the evolution of isocyanates will shape next-generation polymers.

FAQ

A: Primarily in producing polyurethanes for foams, coatings, adhesives, and elastomers.

A: Yes. Many are respiratory sensitizers and require strict handling protocols.

A: Alternatives exist (e.g., NIPUs), but performance trade-offs currently limit widespread adoption.

A: TDI is more volatile and used in flexible foams; MDI is less volatile and common in rigid foams.

A: Through green synthesis, bio-based inputs, and non-isocyanate alternatives.

Want to discover high-performance isocyanate formulations, identify new bio-derived pathways, or forecast patent-driven innovation?

👉 Use PatSnap Eureka AI Agent to benchmark technology leaders, explore scientific literature, and accelerate formulation discovery—smarter and faster.